ARPA-E’s vision for carbon neutral liquid fuels

By Trevor Brown on January 11, 2017

We wrote last month about the US Department of Energy funding ammonia projects through ARPA-E’s REFUEL program (“Renewable Energy to Fuels through Utilization of Energy-dense Liquids”).

Although we introduced the individual projects funded in both the ammonia synthesis category and the ammonia fuel-use category, the REFUEL project merits further analysis as a whole because it describes a roadmap for the development of ammonia fuel systems, and identifies benchmarks for their commercial success.

Source-to-Use Energy Cost

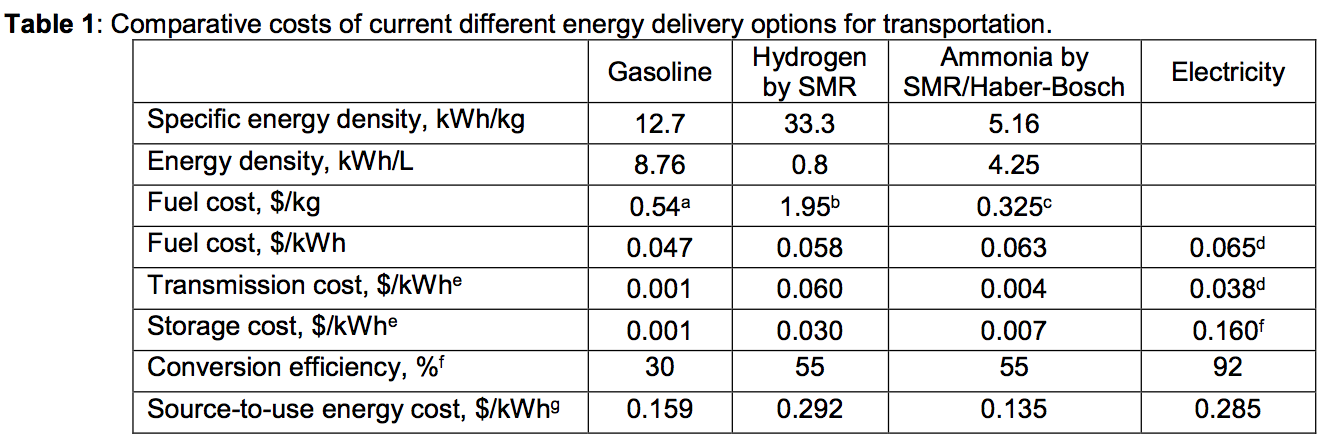

First, the program sets a target of $0.30/kWh as a competitive “source-to-use energy” (SUE) cost, which it defines as the cost of delivered energy, including all production, transmission, storage, and conversion costs and losses – in other words, the energy converted to motive power, not just the primary energy stored in chemical form.

These costs are illustrated in the table below, which compares SUE costs for gasoline, hydrogen, ammonia, and electricity.

It’s worth making a few observations on this table, which looks at today’s technologies (ammonia produced from natural gas) and assumes transportation over a distance of 750 miles by pipeline or high-voltage cable.

- For initial fuel production cost ($/kWh), ammonia is more expensive than gasoline or hydrogen, costing $0.063/kWh to produce.

- But for overall SUE cost, ammonia is less expensive than gasoline or hydrogen or even electricity, costing just $0.135/kWh for delivered power.

- So the additional cost of producing ammonia is more than offset by the cost-savings gained in transportation and storage (relative to hydrogen or electricity) or in conversion efficiency (relative to gasoline).

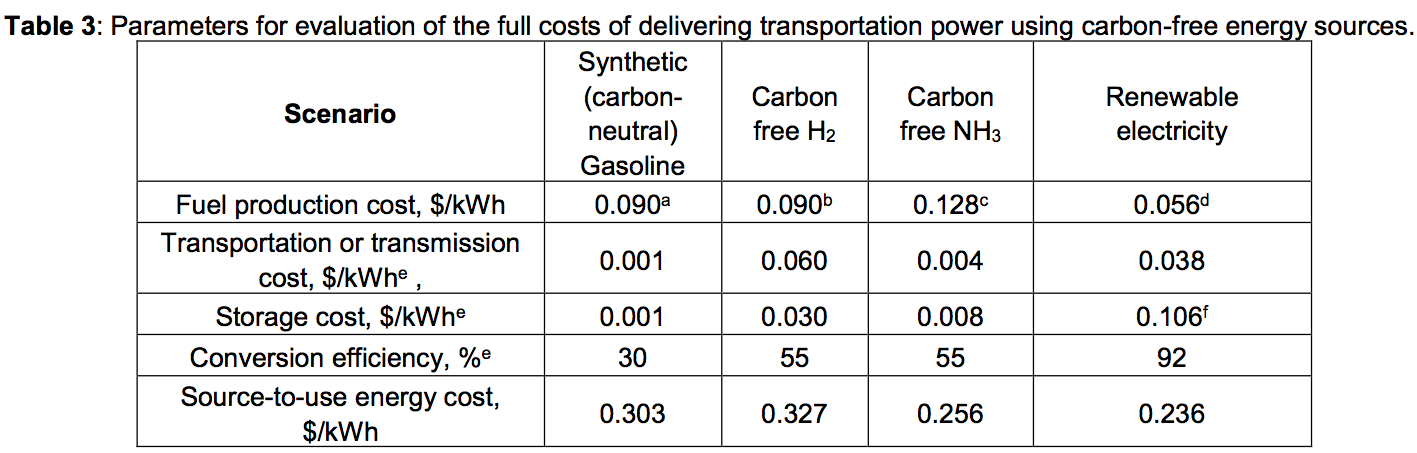

To understand how ARPA-E arrives at the target SUE cost of $0.30/kWh, we need another version of this table – for carbon-neutral technologies. This indicates the cost at which carbon-free ammonia will be competitive against other carbon-free energy sources.

This gives us the $0.30/kWh competitive cost of delivered energy, under the REFUEL assumptions. It also defines a competitive production cost for carbon-free ammonia of $0.128/kWh, which, given ammonia’s specific energy density of 5.16kWh/kg, relates to $0.66/kg or $660 per metric ton.

Address hydrogen infrastructure costs

The table above includes the costs of storing hydrogen at high-pressure (700 bar), which leads to compression losses of 7-19% of the contained energy. For ammonia, which is stored at low pressure (10 bar), the compression losses are just 2-3%.

Beyond comparisons of fuel cost, the REFUEL program sees in ammonia “a viable path to affordable hydrogen refueling stations.” It points out that 75% of the capital cost of a hydrogen refueling station is for compression and storage, with compressor costs increasing “sharply” with size, and reliability presenting a particular issue.

“Continuous cracking” of ammonia “will allow modular capability and increase the station reliability,” while “the use of liquid fuels to generate hydrogen on demand may allow dramatically reduced size and footprint of the storage and compressors.”

Hydrogen storage takes a lot of space, which affects the potential footprint (area) of a refueling station. Tanks to store 300 kg of hydrogen would take up 450 square feet, whereas the same amount of energy could be stored in ammonia tanks taking up just over 50 square feet (a 1,000 gallon tank, with a footprint of about 15 x 3.5 feet). Moreover, the ammonia tank would be stored underground, essentially eliminating storage space as a limiting factor for site selection for hydrogen refueling stations.

Match production capacity to scale of renewables

The REFUEL program also quantifies the case for ammonia as a means of energy storage, “if the scale and production capacity can be matched to regional variabilities in electric power supply.”

Using ammonia as energy storage could allow for a significantly greater penetration of renewables, which are currently “limited by restricted power flow control options for the grid, grid resilience, intermittency, poor long-term predictability, and poor geographic matching of supply and demand.” This is needed because, “if the present grid structure continues, it is estimated that from 5.5% to 21% of variable generation (100-400 TWh) will be curtailed in 2050 at 50% renewables penetration. Further increasing the renewables penetration to 80% would require 95-115 GW of storage capacity.”

To match carbon-free fuel production to renewable power generation, the REFUEL project defines the appropriate ammonia plant scale as 150 MW, based on an average size of 150 MW for solar plants and 80-350 MW for wind plants.

This means that these new ammonia synthesis technologies should be optimized for a peak production capacity of 10-25 tons per hour or 240-600 tons per day: roughly one fifth the size of a new Haber-Bosch plant.

This is a “peak” capacity, because the ammonia production rate must variable, reflecting the intermittency of the solar or wind power input. REFUEL requires that the technologies “be tolerant to the uncertain and variable nature of renewable energy sources.”

To demonstrate performance under these variable conditions, each of the funded synthesis projects will build a bench scale reactor or short stack prototype. “The process should be demonstrated with a prototype … in a continuous (500 hours) operation with at least 5 interruptions designed to test the effect of intermittency in power supply.”

Innovate by developing fuel-use and fuel-synthesis together

One of the central tenets of the REFUEL program is that fuel synthesis technologies and fuel use technologies should be developed jointly. “Fuels research is often conducted with a focus on either production or conversion. ARPA-E seeks to advance a research and development agenda in which both sides are considered and optimized to enable innovation in this area.”

An additional objective of the REFUEL program is to create a research community, from various backgrounds and disciplines …

Implementation of the aggressive targets of the REFUEL program will require R&D teams to be built from several communities, including: electrocatalysis, heterogeneous catalysis, materials science, electrochemical systems design, gas separation, process engineering, and systems integration.

ARPA-E, “REFUEL” program technical overview

Although only one of the projects announced so far will be co-developing technologies for both synthesis and use, ARPA-E clearly sees cross-disciplinary collaboration as the solution to this optimization challenge.

You can read the full and highly detailed (and densely referenced) REFUEL Technical Overview, or read our earlier articles introducing the individual projects funded in the ammonia synthesis and ammonia fuel-use categories.