Alternative synthesis start-ups: exploring the growing ecosystem in Australia and New Zealand

By Julian Atchison on July 18, 2023

Electrochemical ammonia

Since 2021, Jupiter Ionics has been developing its electrolytic cell technology to produce ammonia via power, air and water. Inside the cell, an electrochemical pathway is followed that directly reduces nitrogen in the presence of a catalyst, with a proton source providing the other building blocks needed for an ammonia molecule. This chemical reaction occurs at much lower temperatures and pressures than the conventional Haber Bosch process, and at a much smaller scale, opening up the possibility of decentralised, on-demand production of ammonia via renewable electricity, air and water. In Newcastle we’ll hear an update on where Jupiter’s technology advancement is up to, as well as future plans.

Miniaturised Haber-Bosch

NZ-based Liquium was formed as a commercialisation spin-out from the University of Wellington in 2017. A patented, small-scale Haber Bosch reactor was the outcome of several years of research by Professor Franck Natali’s team, with Liquium looking to take the technology on its next commercialisation steps. Liquium will shortly open a new investment round to scale up and deploy a 100 kg/day ammonia reactor at a pilot facility in New Zealand. CEO Paul Geraghty will share details of this soon-to-open round, as well as taking our audience through progress made to date on Liquium’s technology.

Alternative chemical pathways

The AMMONIAC “chemical-looping” system for distributed ammonia production has been under development at the University of Newcastle for the last decade. A new, $18 million partnership with technology developer Element One will further progress the project. Phase one will focus on the development and validation of a prototype, while phase two will be dedicated to the construction, commissioning, and operation of a 10 tonnes/day ammonia reference plant at a site in Queensland. Laureate Professor Behdad Moghtaderi joins us in Newcastle to take us through the technology package, and its potential in the Australian agricultural sector.

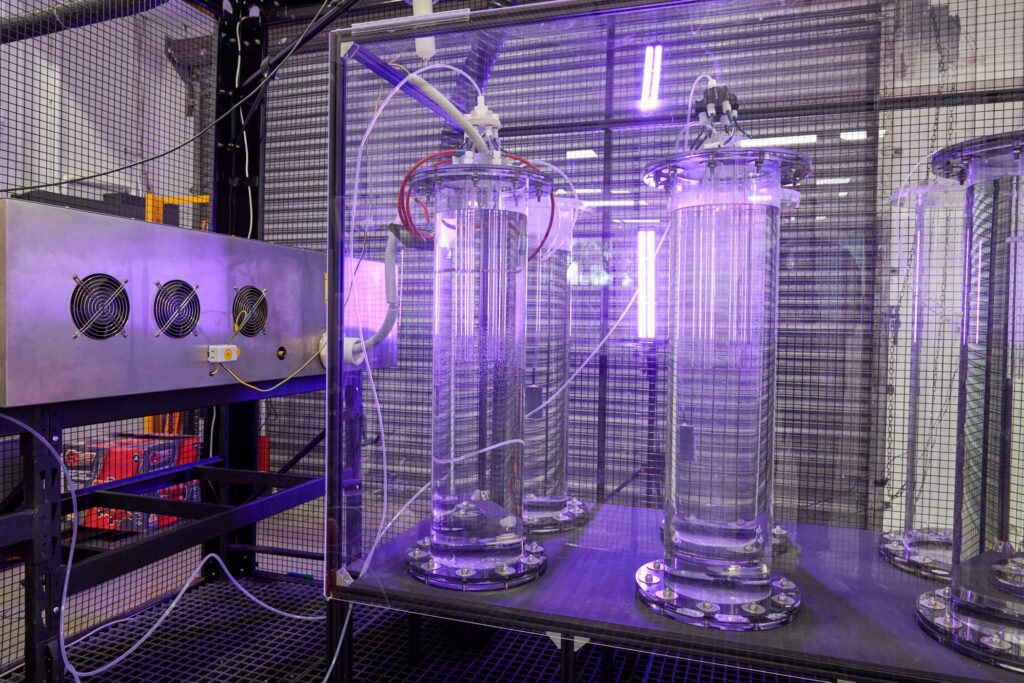

Plasma-based ammonia

Sydney-based PlasmaLeap is commercialising a plasma-based process for ammonia production from air, water and electricity. Activated plasma produces intermediary NOx molecules contained in solution, which are then electrochemically converted to ammonia. PlasmaLeap is targeting an energy efficiency of 20 kWh/kg of ammonia produced by its large-scale reactors, making it commercially viable compared to conventional ammonia by the end of this year. An on-farm trial in Tasmania is already planned.