Ammonia Included in Australian Study of Novel Combustion Technology

By Stephen H. Crolius on February 08, 2019

The most recent meeting of the Ammonia Energy Association-Australia was held on December 6, 2018. Ciaran McDonnell-Worth, the organization’s coordinator, reported that there was “excellent discussion throughout the meeting which was bolstered by the presence of several new participants.” One of those participants, Bassam Dally, Mechanical Engineering Professor at the University of Adelaide, spoke about a novel technology for ammonia combustion that may have application in high-temperature industrial processes and beyond.

There are several variants of the technology and several names that come into play. The name for one variant – “moderate or intense low-oxygen dilution (MILD) combustion” – points to the amount of local oxidant in the combustion environment as one key process parameter. The name for another – “flameless oxidation” – points to the lack of a visible flame as the technology’s most evident result. An early description of the technology was provided by Joachim Wünning, an engineer who serves as the General Manager of the German industrial burner producer WS Wärmeprozesstechnik GmbH, in a 1991 paper published in the journal Chemie Ingenieur Technik. In a later paper, Wünning described his moment of discovery:

In 1989, a surprising phenomenon was observed during experiments with a self recuperative burner. At furnace temperatures of 1000°C and about 650°C air preheat temperature, no flame could be seen and no UV-signal could be detected. Despite that, the fuel was completely burnt. The carbon-monoxide content in the exhaust was below 1ppm. The NOx emissions were close to zero, in the single digits, what was first thought to be a malfunction of the NO-analyser. The combustion was stable and smooth.

Flameless Oxidation, Joachim Wünning, 6th HiTACG Symposium, 2005

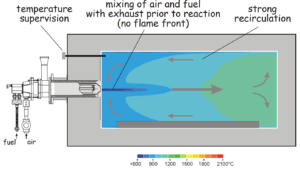

Click to enlarge. “Main characteristics of flameless oxidation.” Flameless Oxidation, Joachim Wünning, 6th HiTACG Symposium, 2005

Wünning’s subsequent research illuminated the “essential conditions” for flameless oxidation. Per his 2005 paper, “fuel and air jets have to be mixed into a strong recirculating flow of exhaust prior to reaction.” The controlled flow of exhaust is so critical, in fact, that Wünning identifies it as the sole indispensable factor in his ultimate definition of the process: “Flameless oxidation is stable combustion without a flame and with defined recirculation of hot combustion products.”

In an Ammonia Energy interview this week, Dally said that MILD combustion has two key advantages over the conventional process. One, reduced formation of nitrogen oxides (NOx), is a function of the relatively low, and homogenous, temperature of MILD combustion, which generally occurs at temperatures below 1,200 degrees C. Conventional combustion of hydrocarbon fuels is characterized by flame temperatures in excess of 2,000 degrees C. NOx formation generally becomes problematic when temperatures in the combustion environment exceed 1,500 degrees C.

The second advantage of MILD combustion is efficiency of heating. Whereas one might intuitively expect that the higher the combustion temperature, the more readily a proximate object might be warmed, in fact the “delta T” effect is trumped by another factor in a MILD environment. This is the release of heat over a larger volume. Flames are hot but highly localized. MILD combustion is cooler but occurs in a broad zone. As a result, according to Dally, “net radiation flux can be 30% higher.”

Flameless combustion has been adopted primarily by industrial customers since its commercialization in the 1990s. Dally says that 74% of the energy used by industry takes the form of heat, which creates a significant opportunity for cost savings from higher heating efficiency and reduced NOx generation. In his 2005 paper, Wünning cites the steel, metals, glass, and chemical industries as the most important opportunities for the technology, while also mentioning possible applications in electricity generation and combined heat and power.

Dally said that he and his group at the University’s Centre for Energy Technology see a particularly strong case for MILD combustion technology in the mining sector. He said they are working with mining company Alcoa on a multi-faceted program aimed at overhauling the company’s energy-consuming processes.

Dally said he became interested in the possibility of ammonia as a MILD combustion fuel based on the broad Australian interest in ammonia as a possible constituent of a hydrogen energy economy. He sees a natural fit between ammonia’s inherent combustion characteristics (e.g., low flame speed) and MILD combustion dynamics, saying “they definitely can go together.” The slides Dally shared at the Ammonia Energy Association-Australia meeting describe the properties of MILD ammonia combustion: “At elevated temperatures ammonia decomposes in the sub-stoichiometric region of the jet and produces radicals to accelerate the combustion of ammonia . . . MILD combustion results in reduced NOx emission due to an active reburn mechanism.”

In late 2018, Dally and his colleagues were awarded an Australian Research Council grant of AUD$520,000 (USD$371,000) for a project entitled Adaptation of carbon free fuels to high temperature industrial processes. The goal is to explore the applicability of MILD combustion to the fuels of tomorrow:

This project aims to deepen our understanding of the underpinning scientific and engineering solutions required to adapt carbon free renewable fuels to high temperature industrial processes. The project will advance the knowledge base of innovative strategies, such as fuel blending and oxidant stream vitiation needed to replace fossil based fuels with alternatives such as hydrogen, or ammonia. Advance experimental and computational tools will be used to investigate the controlling parameters to facilitate adaptation including burning characteristics, modes of heat transfer and pollutant emissions.

Grant Award View – GA28362, Australian Research Council, December 18, 2018

Work on the project is just underway and will continue through the end of 2021.