Carbon intensity of fossil ammonia in a net-zero world

By Trevor Brown on January 14, 2021

In discussions of carbon capture technology for low-carbon ammonia production, there are two informal rule-of-thumb numbers: 60% and 90%.

We know we can capture, at very little additional cost, over 60% of the CO2 from a natural gas-based ammonia plant because this is the process gas (the byproduct of hydrogen production). Many ammonia plants already utilize this pure CO2 stream to produce urea or to sell as food grade CO2. The remaining CO2 emissions are in the much more dilute flue gas (the product of fuel combustion to power the process). For some decades we have assumed we could capture most of this but the lingering question has always been: how much of that flue gas is economically feasible to capture?

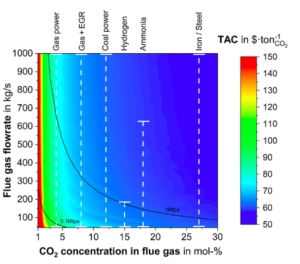

A team of researchers at Imperial College London has just published a fascinating study into this question, entitled “Beyond 90% capture: Possible, but at what cost?” The paper quantifies the tipping point — ranging from 90% to 99%, depending on flow rates and concentration — beyond which it is easier to capture CO2 directly from the air than it is to capture more flue gas emissions.

If 100% capture is infeasible, how do we hit net zero?

The context for this research is the movement towards “net-zero” GHG emission targets, which have now been announced by a range of countries, recently including Japan, and companies, including ammonia producers like Yara and CF Industries.

The paper argues that because we will never capture 100% of flue gas emissions but we must achieve 100% CO2 reduction to meet net-zero targets, it will be necessary to co-develop two independent technologies: carbon capture from flue gas (eg, power plants, ammonia plants) and carbon dioxide removal (CDR). The team defines CDR as “a suite of technologies that cover amongst others: afforestation, Bio-Energy with CCS (BECCS), and direct air capture (and carbon storage) DAC(CS)”).

To meet net-zero targets, the CO2 capture rate should be as high as economically viable and as close to 100% as technically possible. However …

A capture rate of 100% is very challenging with an absorption-based system and residual emissions will need to be indirectly captured by CDR. The economic viability will further limit the capture rate to the range of 90–99%. In other words, it would be easier to recover that final one percent from air, as opposed to trying to capture it directly from the processed flue gas. In this context, it is imperative to be clear that the use of indirect capture via CDR to deliver net-zero emissions is not an alternative to mitigation. Rather, it is an integrally co-deployed technology to deliver net-zero in an affordable way.

MacDowell et al, Beyond 90% capture: Possible, but at what cost?, International Journal of Greenhouse Gas Control, February 2021

This call for “co-deployment” of carbon capture and carbon removal technologies is, in my view, a welcome development.

Moreover, given that it is increasingly likely that atmospheric CDR will need to be scaled up post-2050 to deliver a globally net-negative paradigm, this approach of early co-deployment will help bootstrap the creation of this new industry.

MacDowell et al, Beyond 90% capture: Possible, but at what cost?, International Journal of Greenhouse Gas Control, February 2021

Why not stop combusting fossil fuels?

There is of course a strong argument to make here for all flavors of renewable and nuclear energy. But there is also a recent trend towards new fossil-based technologies that omit the CO2 emissions.

Net Power recently announced that it has four power plants under construction using the Allam-Fetvedt Cycle, which employs pure, supercritical CO2 from natural gas as the working fluid (instead of steam) to drive a turbine. As a result, in theory, all of the CO2 can be captured and sequestered (in practice, I am not aware of any information regarding expected levels of CO2 slip or other life-cycle emissions). As we wrote in February 2019, the company has proposed co-production of hydrogen and ammonia using this process.

Methane pyrolysis, a technology that produces solid carbon instead of CO2 from natural gas, is another potential contributor to a fossil-fueled net-zero future. As always, residual life-cycle emissions (eg, upstream methane slip) must be addressed but eliminating these emissions is increasingly a fundamental business position. This much was demonstrated by Monolith Materials’ recent announcement with Nebraska Public Power District regarding purchasing renewable power for its $1 billion expansion — making a single ammonia plant the largest electricity consumer in Nebraska, and all of it renewable.

And, of course, for the power sector, eliminating CO2 emissions completely will be significantly easier when the fuel molecule no longer contains carbon — even Net Power will have to do something with all of its pure CO2. As Japanese power producer JERA announced in October 2020, its net-zero target is supported by a technology roadmap that begins with co-firing coal and ammonia (in an 80:20 ratio by energy content) and over time replaces coal-fired boilers with 100% ammonia-fired turbines. As stated last month in METI’s new Green Growth Strategy, the 20 million tons per year of ammonia required to co-fire its fleet of 40 coal-powered plants would increase to 100 million tons per year if ammonia were to be deployed as a mono-fuel at the same scale.

For ammonia to make sense as a net-zero solution for power generation, or any application, we must of course eliminate 100% of the emissions from ammonia production. And to achieve this, as this new paper demonstrates, emissions that cannot be captured directly must be captured indirectly.