New offshore export jetty design receives AiP

By Julian Atchison on October 06, 2022

SBM Offshore and Imodco’s Ammonia CALM Terminal design has been granted Approval in Principle (AiP) by DNV. SBM Offshore first deployed the buoy technology in 1959, and in 2014 created subsidiary Imodco to handle its CALM terminal business. The technology may be well proven, but this is the first time it has been applied to shore-to-ship (and vice-versa) liquid ammonia transfer. For ammonia production projects in remote locations – or even those projects where no port infrastructure is possible – offshore mooring presents a huge opportunity to reduce impacts.

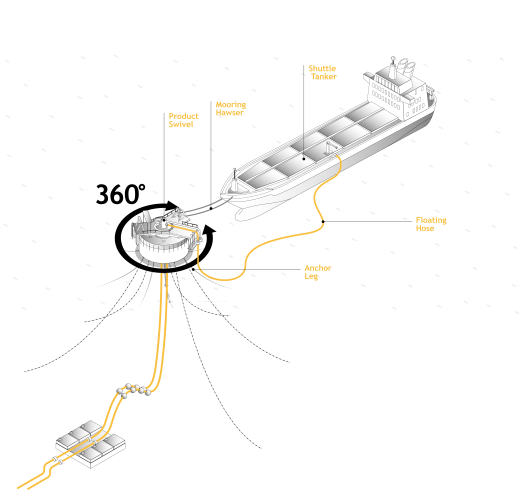

The Catenary Anchor Leg Mooring (CALM) or Single Point Mooring (SPM) system is a buoy that performs the dual function of keeping a tanker moored and transferring fluids, from tanker to shore -and vice-versa- via a subsea pipeline, while allowing the ship to weathervane…They are used for a variety of applications, water depths and vessel sizes ranging from small product carriers to Very Large Crude Carriers (VLCC).

CALM systems are securely anchored offshore, permitting cargo operations to continue in almost all weather and sea conditions. Floating hoses, which rotate around the SPM terminal with the tanker, connect the ship’s cargo manifolds to the SPM. Other hoses connect the underside of the SPM to the submarine pipelines at the seabed via a Pipeline End Manifold (PLEM).

Technology explanation & applications, from Imodco’s website

Jettyless export

This May we reported that ECONNECT Energy would deploy its “jettyless” ammonia transfer terminal in Vietnam, enabling export of renewable ammonia from a project being developed by The Green Solutions. ECONNECT’s IQuay technology was first deployed for LNG transfer in 2017, and was also designed to work with liquid carbon dioxide and ammonia.