Nutrien planing world-scale clean ammonia facility in Geismar, Louisiana

By Julian Atchison on May 26, 2022

Nutrien is currently evaluating Geismar, Louisiana as the location for a $2 billion, million-tonne-per-year CCS ammonia production facility. FID is expected next year, with construction to begin in 2024 and operations in 2027. Agreements have been signed with Denbury, who will handle the construction & operation of necessary CCS infrastructure, and also Mitsubishi Corporation, who have agreed to off take up to 40% of the produced ammonia, which will be exported to the “Asian fuel market”.

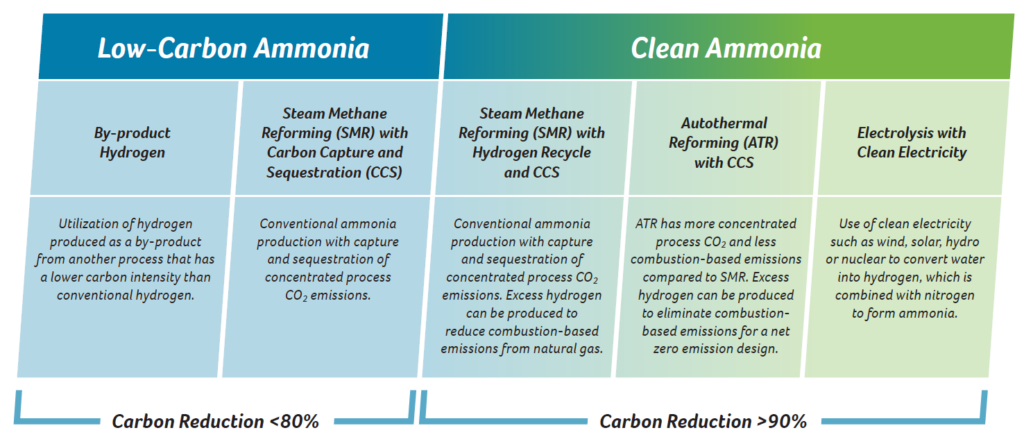

The new clean ammonia plant would leverage low-cost natural gas, tidewater access to world markets, and high-quality carbon capture and sequestration infrastructure at its existing Geismar, LA facility to serve growing demand in agriculture, industrial and emerging energy markets. The plant is expected to have an annual production capacity of 1.2 million metric tonnes of clean ammonia and capture at least 90 percent of CO2 emissions, permanently sequestering more than 1.8 million metric tonnes of CO2 in dedicated geological storage per annum. The new plant will use auto thermal reforming technology to achieve the lowest carbon footprint of any plant at this scale and has the potential to transition to net-zero emissions with future modifications.

Project details from Nutrien’s official press release, 18 May 2022

Leveraging existing technology & partnerships

Nutrien already operates an ammonia & fertiliser production facility in Geismar, with Denbury capturing & utilising CO2 from this plant for enhanced oil recovery since 2013. The pair will build on this successful team-up in developing the new facility, with CO2 emissions to be captured, transported and sequestered underground. Denbury currently has rights to permanent sequestration sites in Texas, Louisiana and Alabama, totaling around 1.4 billion tonnes capacity.

Nutrien’s technology pathway to 90% emissions reduction in ammonia production processes is well-established. As indicated in the press release, the new facility will use auto-thermal reforming coupled with CCS, a pathway that minimises fuel combustion emissions (which are much more difficult and expensive to capture than process emissions). There is also the option to employ hydrogen recycling, a process that directs excess hydrogen from syngas conditioning back to the start of the process, where it acts as a fuel input, displacing natural gas. More information can be found in Nutrien’s white paper Ammonia: Transitioning to a Net-Zero Future.