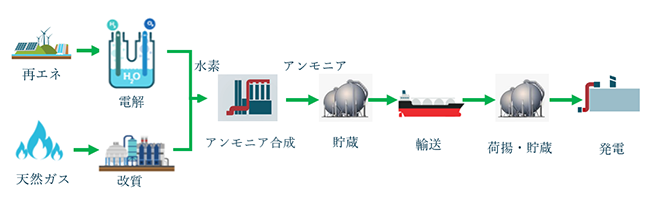

Hydrogen Filling Stations: techno-economic analysis of on-site ammonia reforming and H2 purification

This month, a team of researchers from Fuzhou University in Fujian, China, published a new paper in the journal Sustainable Energy & Fuels that provides a “Techno-economic analysis and comprehensive optimization of an on-site hydrogen refuelling station system using ammonia.” The study concludes that “the H2 production cost of the NH3-fed on-site hydrogen refuelling station was at least 15% lower than other carbon-free routes (such as electrolysis, solar thermolysis, photo-electrolysis, etc.), and comparable to that of a methane steam reforming system with carbon capture and storage.”