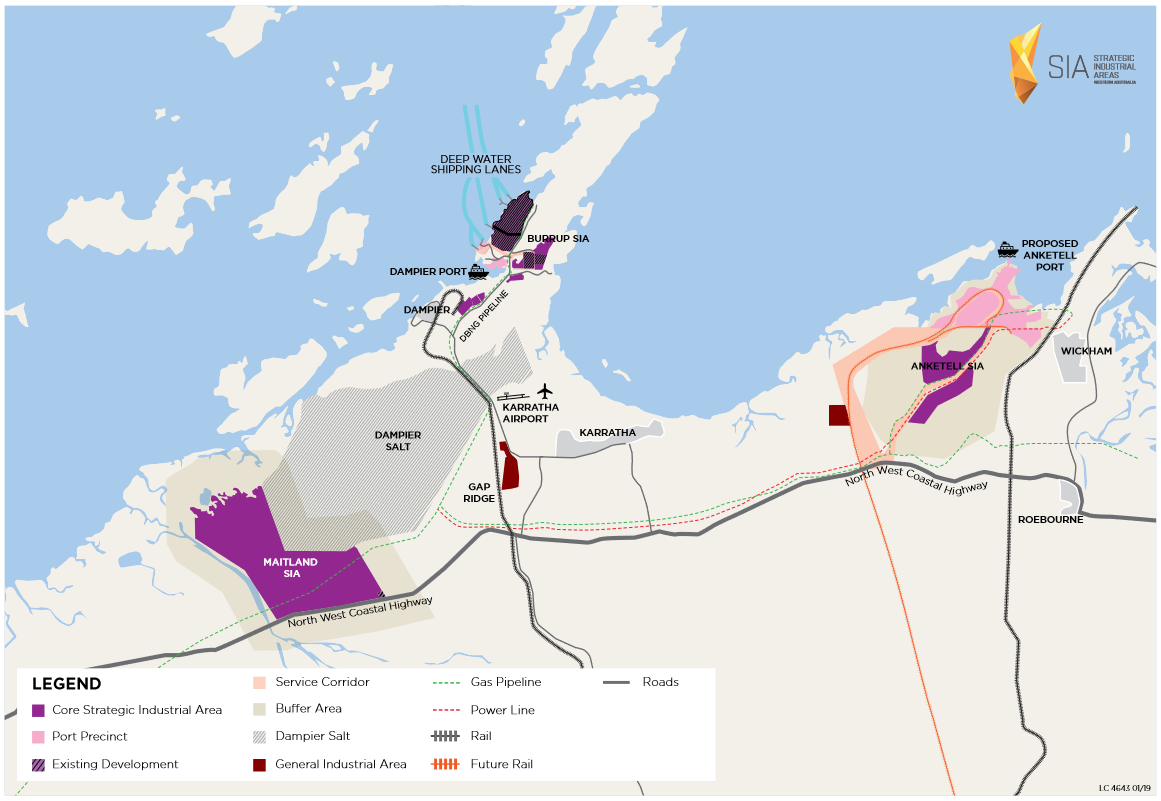

First Ammonia to produce renewable ammonia at the Port of Victoria

First Ammonia and the Port of Victoria have announced a partnership to produce renewable ammonia at the Port on Texas’ Gulf Coast. Electrolytic hydrogen feedstock will be produced via renewable energy, with the ammonia plant expected to be fully operational in 2025.