AFC Energy: Power Tower & off road racing

Two updates from AFC Energy:

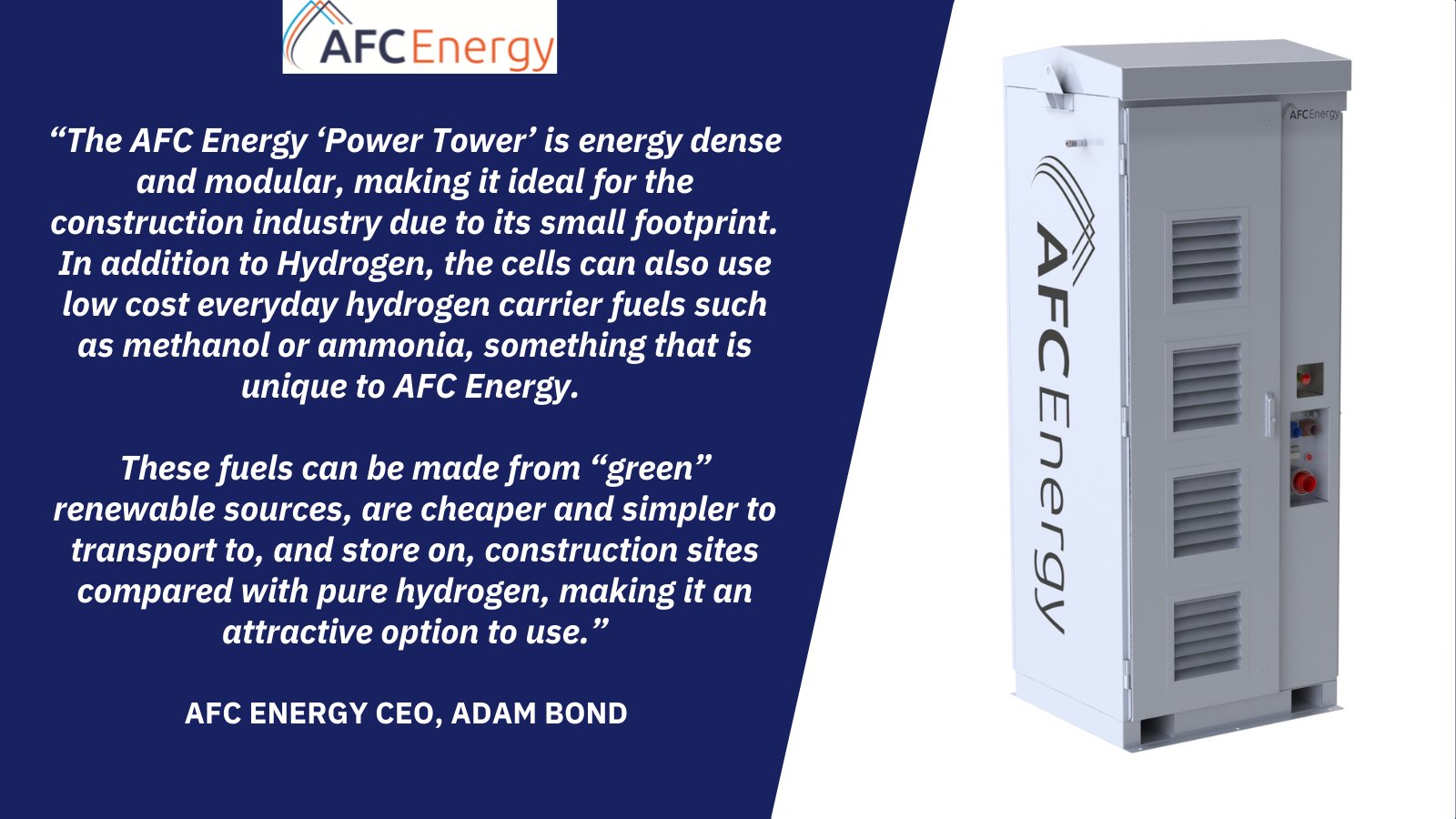

1. The “Power Tower”, a 10kW, ammonia-fueled, off-grid power was launched last month, with Keltbray and Acciona to deploy modular units on construction sites mid-year.

2. The launch of Extreme-H off road racing, with green methanol and ammonia likely to act as hydrogen carriers for the hydrogen-fueled racing championship.