Pathways to electrolysis success for USA, Australia

By Julian Atchison on December 16, 2024

Department of Energy: $1/kg production cost still achievable

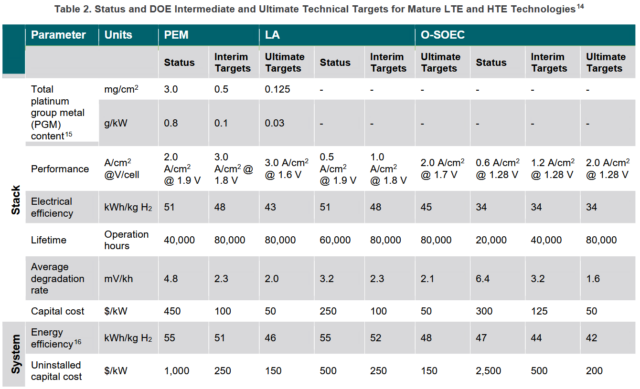

Click to enlarge. Performance and capital cost targets for various electrolyser technologies to reach the $1/kg Hydrogen Shot goal by 2030. Table 2 from Hydrogen Shot: Water Electrolysis Technology Assessment (US DoE, Dec 2024).

New analysis from the US Department of Energy highlights ways to reduce the cost of producing hydrogen via electrolysis. In order to achieve the aggressive Hydrogen Shot initiative goal of $1/kg by 2030, DoE sets out a series of performance and capital cost targets for established and lower-TRL electrolyser technologies (see right). Manufacturing these technologies at high volume to achieve economies of scale, lower-cost manufacturing processes, and technology advances across the material, cell/stack, and system levels are all critical to meet these targets.

The higher-TRL electrolyzers (PEM, LA, and O-SOEC) are targeting to meet the interim target of an LCOH of $2/kg by 2026 and the ultimate target of $1/kg H2 by 2031.13 AEM electrolyzers are aiming to achieve targets similar to PEM, and P-SOEC electrolyzers are expected to achieve targets similar to O-SOEC, though timelines for meeting cost goals will vary depending on investments. While the lower-TRL technologies may not achieve $1/kg H2 by 2031, investments in these technologies may eventually lead to even lower hydrogen production costs, as some approaches have advantages over current commercial technologies.

Summary of electrolyser technology abilities to meet $1/kg Hydrogen Shot goals, from Hydrogen Shot: Water Electrolysis Technology Assessment (US DoE, Dec 2024)

The report also highlights that advanced throughput methods for manufacturing electrolyser units will be necessary to drive down capital costs and push closer to the Hydrogen Shot goal. As well as general manufacturing improvements across the technology range, there are technology-unique process steps that can be adopted.

This is the second of three assessments from the DoE into hydrogen production pathways. The first report (Hydrogen Shot Technology Assessment: Thermal Conversion Approaches) shows that technology advancements may reduce production costs from $1.64/kg to $1.40/kg for SMR with CCS, and from $1.60/kg to $1.33/kg for ATR with CCS. A third and final report will explore “advanced pathways” for hydrogen production, including the use of sunlight to split water (instead of electricity).

CSIRO: $1.7 billion manufacturing opportunity

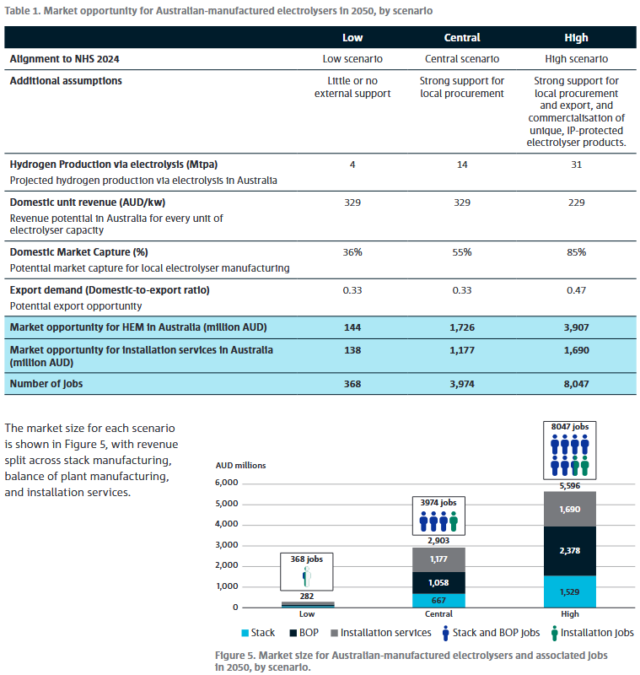

Click to enlarge. Market opportunity for Australian-manufactured electrolysers in 2050, with three modeled scenarios. Table 1 and Fig 5 from Hydrogen Electrolyser Manufacturing: A strategic guide for seizing Australia’s clean-tech manufacturing opportunity (CSIRO, Oct 2024).

In a new report, Australia’s national science agency CSIRO projects that Australia’s hydrogen electrolyser manufacturing sector could generate AU$1.7 billion in revenue annually by 2050, as well as creating 4,000 jobs. In addition, electrolyser installation services could add an additional AU$1.2 billion in revenue and 1,000 jobs by 2050. The report highlights a “strong starting position” for Australia, with an emerging cohort of Australian manufacturers already translating research into commercial applications. Australia also boasts a significant pipeline of renewable hydrogen projects, which creates local demand and supply chain benefits.

Australia has a significant pipeline of renewable hydrogen projects, with specific electrolyser procurement and maintenance needs. If we can use our natural and technical advantages to develop a geographically aligned supply chain, Australia could reap the economic and environmental benefits of owning a significant portion of the electrolyser market.

Patrick Hartley, Leader of CSIRO’s Hydrogen Industry Mission, in his organisation’s official press release, 4 Dec 2024