SalalaH2: export-focused renewable mega-project targets FID in 2026

By Kevin Rouwenhorst on May 21, 2025

In our May Episode of Project Features, Siddiqa Al Lawati from OQ Alternative Energy and Rodolphe Kotliar from Dutco discussed SalalaH2, a renewable ammonia project under development on Oman’s southwestern coast. The recording is available here, and you can also download the speaker presentations.

Oman’s national hydrogen strategy, Hydrom and OQ

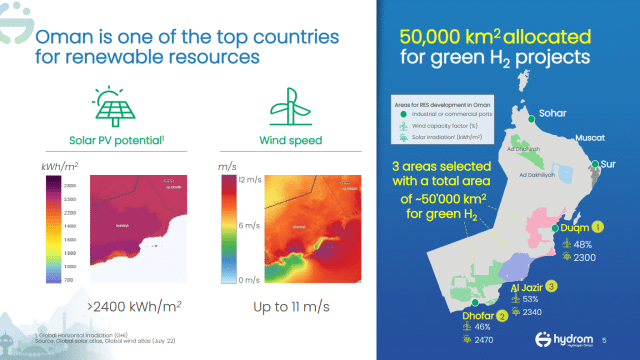

Click to expand. Oman’s solar and wind potential, and industrial renewable hydrogen hubs. Source: Hydrom.

Oman is an existing ammonia producer, with a combined annual capacity in excess of 1.6 million tons of ammonia from two plants, relying solely on gas as feedstock. But, Oman has some of the best complementary solar and wind potential globally. The country published its Green Hydrogen Strategy in 2022, with the aim to produce renewable hydrogen and ammonia for both local consumption and export. The strategy has since been updated, as recently as 2024.

Oman’s Ministry of Energy and Minerals (MEM) sets the national policy and regulatory framework, and created the Directorate General for Renewable Energy and Hydrogen. Government agency Hydrom (Hydrogen Oman) was set up under Energy Development Oman (EDO) in 2022, to structure and accelerate the development of the renewable hydrogen sector in Oman. Hydrom is responsible for developing the ecosystem, including master planning and land allocation, managing project auctions, and coordinating infrastructure development. Various consortia are developing renewable ammonia projects in the Duqm region in the middle of Oman, and in the Salalah region, leveraging the hydrogen frameworks set up in Oman over the past few years.

Government-owned OQ is an integrated energy company, based out of Oman, with existing industrial assets. Its subsidiary OQ Alternative Energy has been designated by the Omani government as the “National Champion for Renewable Energy”, leading renewable energy development and renewable energy supply to industry.

2030 target: production capacity already allocated

The national renewable hydrogen target by 2030 is about 1 million tons (around 5.6 million tons of ammonia equivalent). Through project auctions round 1 and 2 (overseen by Hydrom in 2023 and 2024), this capacity has already been allocated to various project partners and consortia. A total area of 50,000 km2 has been reserved for renewables development and renewable hydrogen development in Oman, for the development of 8.5 million tons of renewable hydrogen by 2050, estimated to require 140 billion USD investment.

SalalaH2

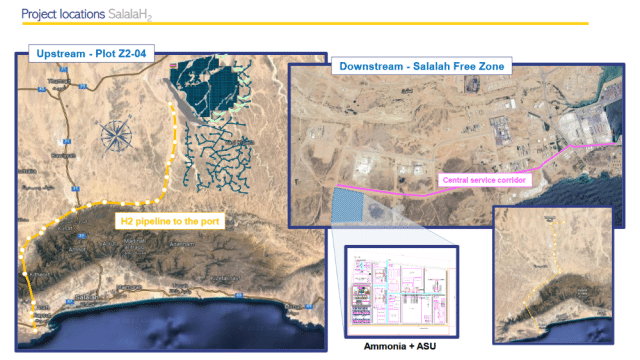

Click to expand. Location of the SalalaH2 project, including key infrastructure. From Rodolphe Kotliar, Export of green NH3 from Oman (May 2025).

Within the SalalaH2 consortium, Marubeni, OQ Alternative Energy, Samsung C&T and Dutco are jointly developing a 1 million tons per year renewable ammonia project in Salalah on Oman’s southwestern coast. 5 GW of wind and solar capacity will power 2 GW of electrolysers. Hydrogen will be transported via a pipeline to the Salalah Free Zone near the Port of Salalah, where the air separation unit for nitrogen purification and ammonia plant will be located. Target offtake markets include Japan, South Korea, and the European Union (the ammonia will be RFNBO-compliant), with contractual volumes of at least 200,000 tons of ammonia per year for long-term offtake (at least 15 years). Ammonia offtake can be FOB (Freight on Board, from the Port of Salalah), or DAP (Delivery at Port, ammonia transport and distributions via project partners).

On the 12th of December 2023, a Project Development Agreement (PDA) was signed with Hydrom, with a concession for land for over 40 years of operation. The expected investment is 5-7 billion USD, with FID aimed for 2026 and operations scheduled in 2030. The consortium aims to build, own, and operate the facilities.

Various activities have been conducted so far, including an Energy Yield Assessment (EYA) for solar-based electricity generation and various proposals from original equipment manufacturers (OEMs), indicating a capacity factor of >30% and energy production of >2750 kWh/kWp per year. A 12 month wind measurement campaign was recently completed, with 7 masts at 100m and 2 Lidars at 80-300m, and the information was compared with national measurements. This indicates a wind capacity factor of >40%, with wind capacity factors especially high in summer.

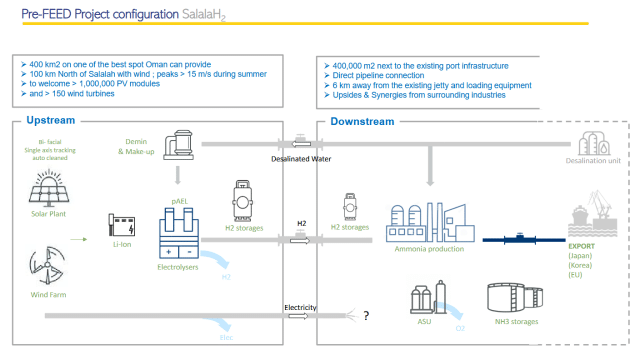

Click to expand. Pre-FEED configuration for SalalaH2 project. From Rodolphe Kotliar, Export of green NH3 from Oman (May 2025).

The pre-FEED study for SalalaH2 conducted by Samsung C&T is concluding this month, with offtake agreements and the FEED as next steps. Over 1 million solar PV panels will be required, and about 150 wind turbines with a capacity of at least 7 MW. Other facilities in the hydrogen production area include pressurized alkaline electrolyzers, battery storage, and hydrogen storage. The downstream ammonia production area will include an air separation unit for nitrogen purification, an ammonia plant, ammonia storage, and a water desalination plant. While utilization of renewable energy resources will certainly make the produced hydrogen and ammonia RFNBO-compliant, the partners are also exploring whether connection to Oman’s national grid will also yield the same result.

Leveraging OQ’s existing infrastructure in Salalah

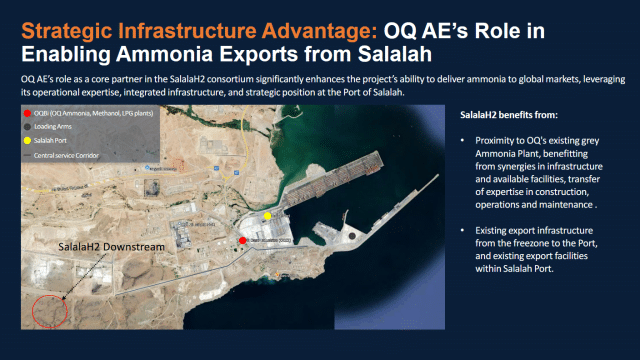

Click to expand. OQ’s existing assets in the Port of Salalah. From Siddiqa Al Lawati, OQ Alternative Energy (May 2025).

The ammonia production plant for the SalalaH2 project will be located in the Salalah Free Zone, close to OQ’s existing gas-based ammonia plant, methanol plant, and LPG plant, as well as the Port of Salalah itself. Proximity to the existing chemical plants allows for synergies, such as leveraging expertise in operations, sharing infrastructure, using existing terminal and port facilities for ammonia exports, as well as using existing maintenance teams and crews.

The Port of Salalah has been recognized as the second most efficient container port in the world, according to the Container Port Performance Index (CPPI) published by the World Bank and S&P Global. The Port of Salalah has an existing ammonia storage terminal, including automated ammonia loading arms, and pipeline infrastructure. Safety measures are in place with leak detection and emergency response systems, regular safety drills, and environmental monitoring such as gas detection.

Reduced emissions of existing ammonia capacity in Salalah

OQ’s existing ammonia plant has been in operation for almost 3 years. The 1,000 tons per day ammonia plant and 3,000 tons per day methanol plant are already highly integrated, reducing the number of processing units required. The purge gas from the methanol plant was previously used to fire the reformer for syngas production. However, the purge gas from methanol production is currently purified using pressure swing adsorption (PSA) to obtain high-purity hydrogen, as feedstock for the ammonia plant.

Plant operator OQBi (OQ Base Industries) claims this results in an energy consumption of around 26.4 gigajoule per ton ammonia on a lower heating value (LHV) basis. This is significantly lower than the industrial base, with IFA’s “global average” benchmark of 36 gigajoule per ton ammonia in 2024. According to OQBi, this results in a carbon footprint of only 1.37 ton CO2 emitted per ton ammonia (excluding upstream emissions from natural gas extraction), with further decarbonization potential down to 1.14 ton CO2 emitted per ton ammonia via electricity grid decarbonization.