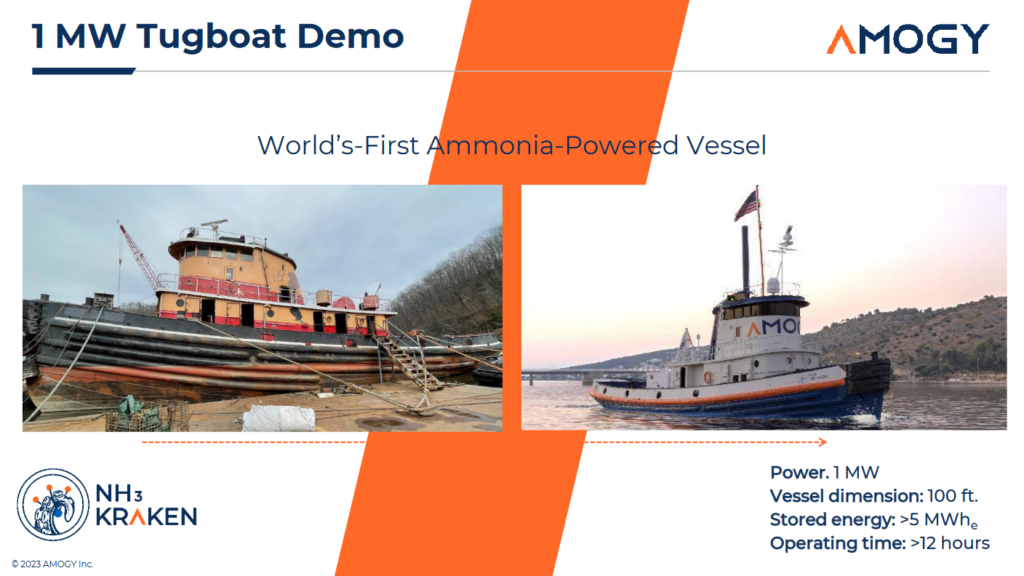

The NH3 Kraken: Amogy’s ammonia-powered tugboat

By Conor Furstenberg Stott on October 05, 2023

Building on the success of their previous technology demonstrations – which featured a 5 kW drone, a 100 kW tractor, and a 300 kW semi-truck – Amogy is now retrofitting a tugboat to be the world’s first ammonia powered vessel.

In this episode of Maritime Insights, Abigail Jablansky (Head of Project Management at Amogy) provided insight into Amogy’s approach to retrofitting the tugboat (dubbed the NH3 Kraken), and Herbert Fowlkes (Chief Safety Consultant at Chief Safety Solutions) described how his organisation is helping to guide Amogy through safety compliance requirements, and how best to work with regulatory bodies like the United States Coast Guard. You can download the speaker’s slides here, and watch a full recording of the conversation here.

Calling in from the shipyard

Calling in from Feeney Shipyard where the tugboat works are taking place, Abigail took us through the origin of Amogy, founded three years ago and currently counting USD 220 million in fundraising. Centered in Brooklyn, they also have a presence in Houston, Norway and Singapore. The tug is 32m in length, was built in 1957, and currently lies at Feeney (about 2 hours north of NYC), where she is being converted to feature a new ammonia to electric powertrain.

Much of the development phase has been asking: “what does ammonia power mean for such a vessel?” The initial physical work stages have required a lot of demolition in preparation for the powerpack and rest of the plant that needs to be installed. While the original hull form remains the same, much needs changing in the interior to accept the new equipment. A specific new space requirement was identified for the ammonia powerpack, including reworking of reinforcement and renewing of the deck and pilot house. Most of the existing internal machinery has been ripped out.

In parallel, on the process design side, Process and Instrumentation Diagram definition continued while placement of equipment was decided, respecting safety requirements for ventilation and fire prevention. A continuous HAZOP evaluation process was required to take such decisions. The first construction phase in the dry dock was mostly in the interior, where the engine room was partitioned off forming the powerpack space and a separate electrical space. Other works included sea chest installation and necessary frame reinforcing. Where weight assumptions and estimations had to be made, strength factors of safety were increased. Hull painting and various pressure testing is now complete, and the vessel is ready for the next phase: receiving the drivetrain plant.

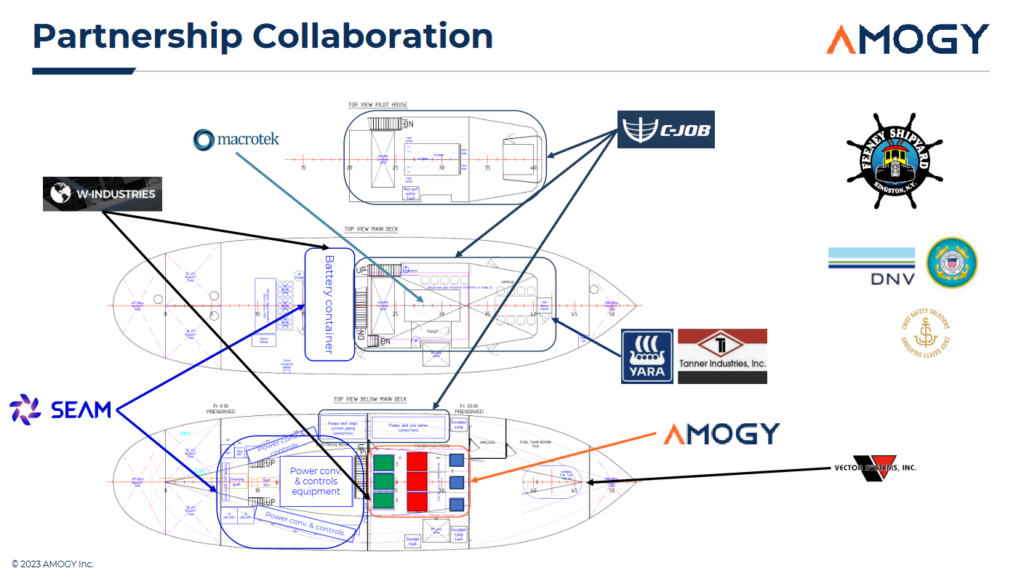

The plan and partners involved

The ammonia tank room is located furthest forward. It is classified as a hazardous zone and includes an airlock, and entry is allowed only when authorized. Vector Systems are supplying the ammonia tank. Immediately aft of this is the Amogy powerpack room including cooling water pumps, scrubbers etc. Aft again, we find the electrical drive components and switchboards (SEAM to supply these).

On the main deck is a forward bunkering station and reconstructed deck house with control room, where data is to be collected and safe operation maintained. There are also batteries installed for backup redundancy and peak shaving. SEAM is the key partner for the power control distribution. Other technology partners include W-Industries, Macrotek, Yara & Tanner Industries. Additional project partners include DNV, Feeney Shipyard, Chief Safety Solutions and the US Coast Guard. C-Job covered the overall naval architecture requirements.

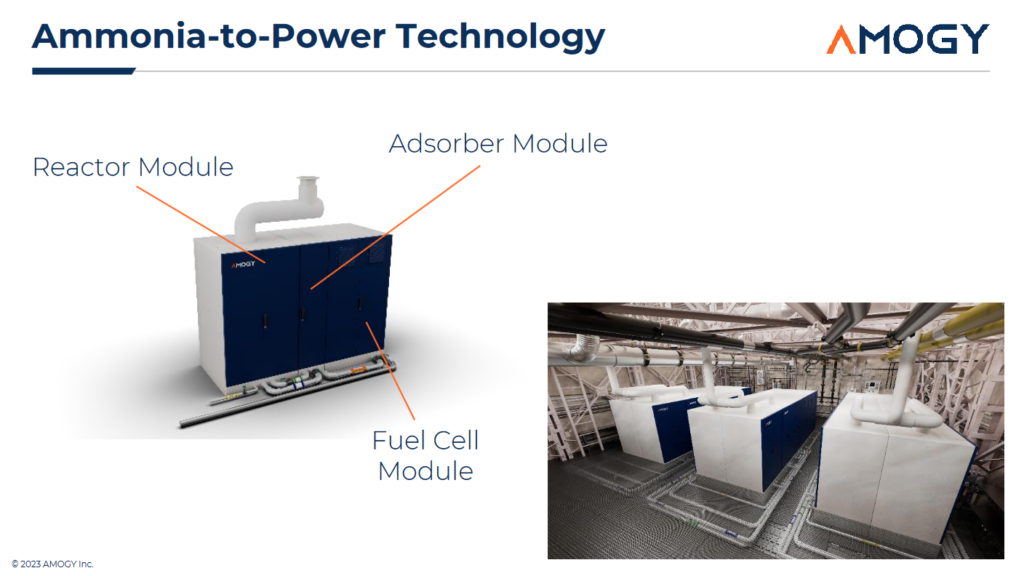

The Amogy Powerpack: three parts

The Amogy powerpack is first composed of a reactor, which cracks the ammonia to nitrogen and hydrogen, then an absorber which removes any residual ammonia from the stream. After this comes the fuel cell module, a low temp PEM which consumes the hydrogen fuel, converting it to electrical energy & water.

The modules will be skid installed and connected to the required piping installation. This method allows for further development & optimisation, and will provide valuable learnings toward future maritime applications (many companies are developing similar, fuel cell-based propulsion systems for maritime vessels). The project is also extremely valuable for Amogy, being the first on-water application for its ammonia-to-power technology. When functioning, the result leverages the best part of hydrogen (its energy potential) but without the worst part (its storage challenges). This is the central value proposition of an on-demand ammonia cracking solution.

Including the Coast Guard

Chief Safety Solutions (CSS) has been critical to unlocking the regulatory aspect of this project work. CSS partnered with Worley Marine Consulting (WMC) to provide a direct communication path to the Sector New York Coast Guard, enabling smooth cooperation with Amogy. The communication journey has thus far been about review of plans for key work packages like Worst Case assessment, Safety Equipment, Sea Trials permission, Regulatory Matrix and construction/installation plan review. WMC, with a strong background in electrical and plant installation, were able to advise on best practice from the Coast Guard point of view. Ongoing, CSS & WMC will assist with onsite construction execution and crew training.

To date, Amogy has been extremely transparent with their project & proactive in providing information. The willingness to take advice from CSS, WMC and the New York Coast Guard has not gone unnoticed, and the open dialogue has allowed significant progress.

How to start such a project?

Starting this project was challenging. The first conversation was with C-Job, who helped Amogy identify the appropriate vessel type for conversion. Following this, the huge amount of interest shown by potential partners across the value chain was key to building momentum. Everyone involved has been willing to bring in their own existing insights, but remain flexible to ensure steady progress.

The difference with a “regular” conversion of such a vessel is that regulations are missing for ammonia. Technology development is moving faster than regulatory progress, so the methodology is to throw all possible safety requirements in at first, and scale back later if appropriate. This process has had the effect of speeding up the regulatory development mission at the US Coast Guard – a valuable outcome. In the course of conversation Abigail remarked that “being the first, we get a lot of possibly excessive safety measures – but that’s necessary.”

HAZOPs well advanced

There have been two HAZOPs completed with C-Job and DNV. The first covered vessel design, including specifics around the powerpack and the new Amogy technology itself. The vessel part drew from vessel design requirements, existing alternative fuels standards and already available provisional Class rules for ammonia-powered vessels. The second HAZOP was a review of the first – meant to both stress test the original and to bring in any changes or elements which were not covered in sufficient detail. So, the established circular workflow process of Design – HAZOP – Closeout – Recycle is well advanced with the NH3 Kraken project.

What’s next?

Like so many projects of this type, commercialization is the destination. This is also the final Amogy technology application demonstration, completing the journey to MW-scale Amogy wants to use this project to better understand product development in the maritime industry, making this vessel a kind of “internal customer”. Amogy will target a few key markets, and scale up is imminent. With 2 – 3 million tonnes of blue and green ammonia production expected to come online annually from later this decade, Amogy is positioning itself to have the technology ready to use this fuel supply. Thus, Norway and Singapore are strategically active places for them to operate in , and they are among the first movers.