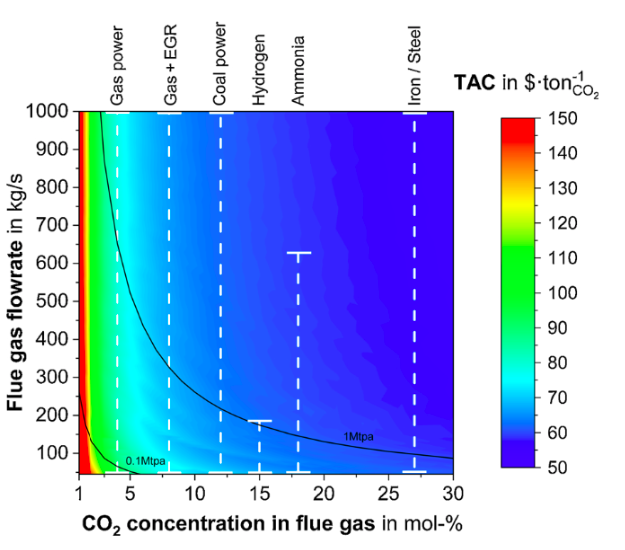

In discussions of carbon capture technology for low-carbon ammonia production, there are two informal rule-of-thumb numbers: 60% and 90%. We know we can capture, at very little additional cost, over 60% of the CO2 from a natural gas-based ammonia plant because this is the process gas (the byproduct of hydrogen production). Many ammonia plants already utilize this pure CO2 stream to produce urea or to sell as food grade CO2. The remaining CO2 emissions are in the much more dilute flue gas (the product of fuel combustion to power the process). For some decades we have assumed we could capture most of this but the lingering question has always been: how much of that flue gas is economically feasible to capture? A team of researchers at Imperial College London has just published a fascinating study into this question, entitled “Beyond 90% capture: Possible, but at what cost?” The paper quantifies the tipping point — ranging from 90% to 99%, depending on flow rates and concentration — beyond which it is easier to capture CO2 directly from the air than it is to capture more flue gas emissions.