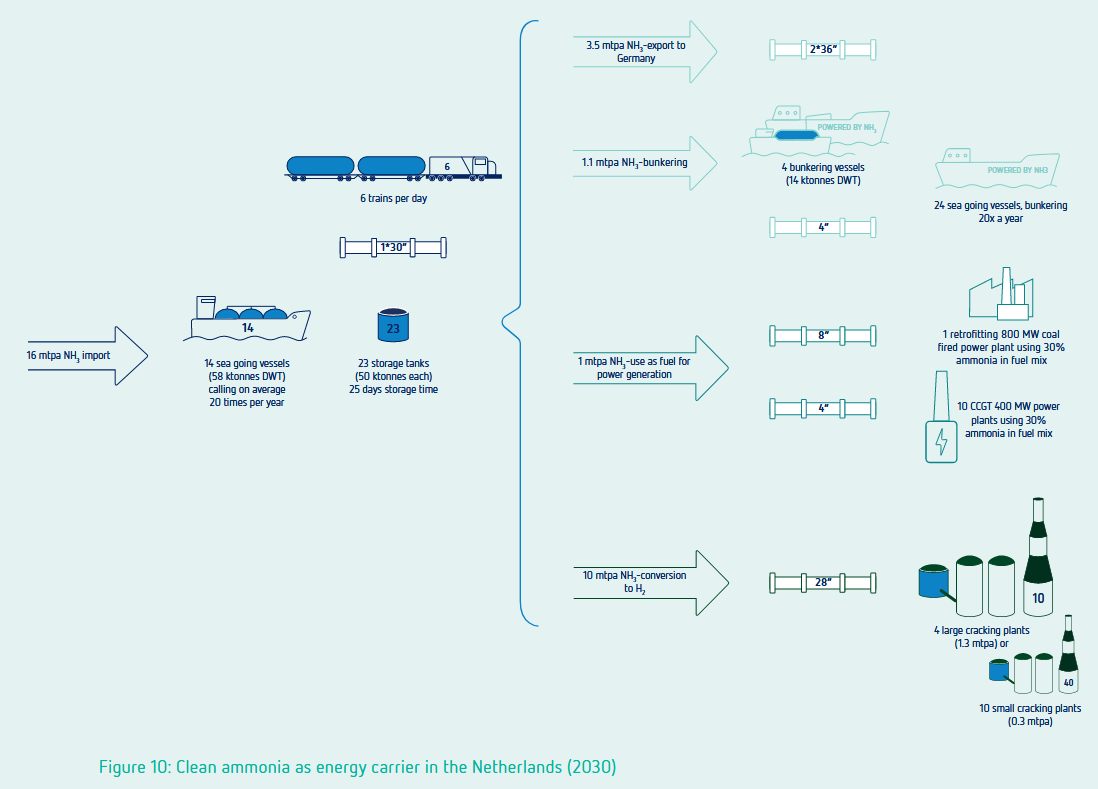

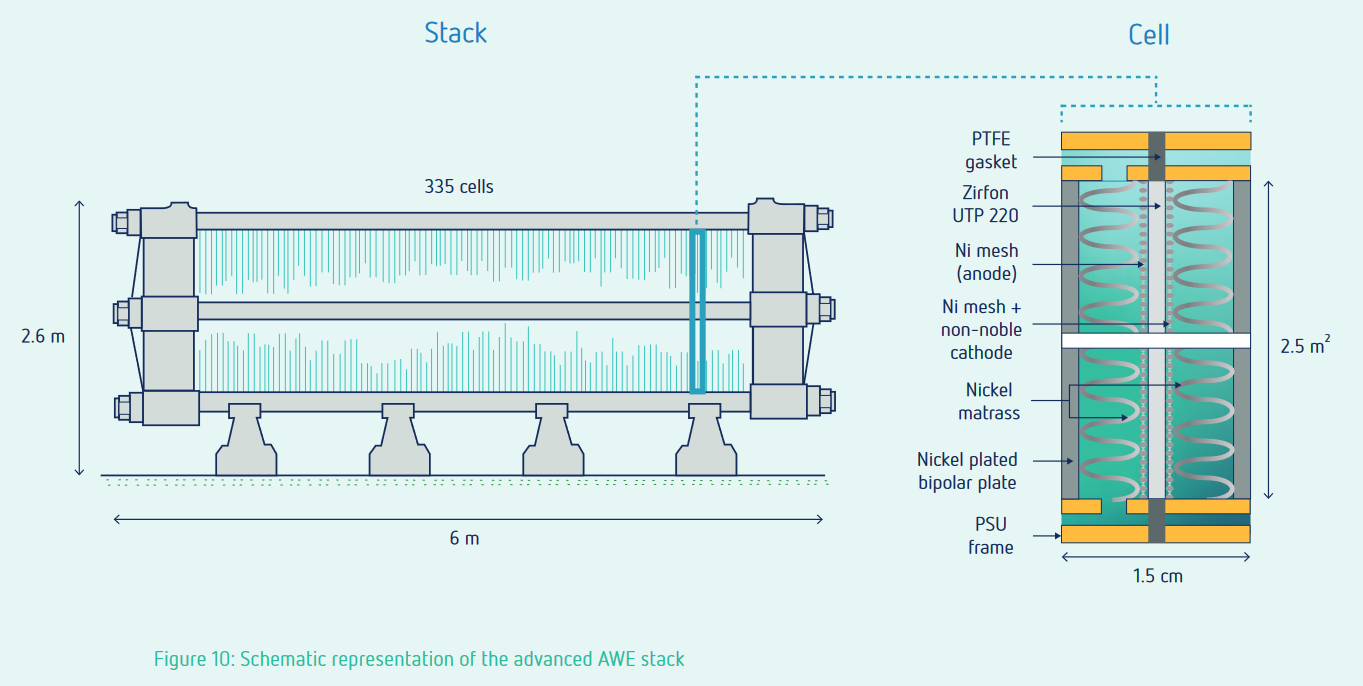

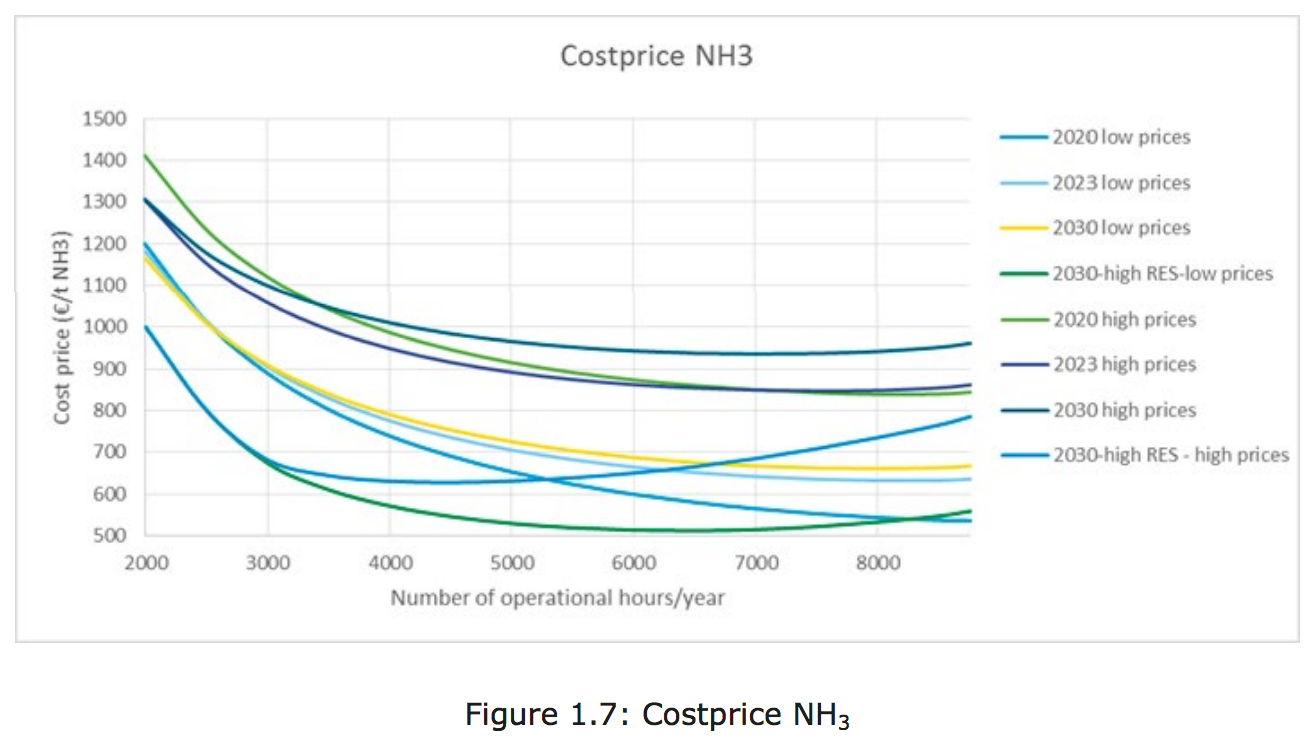

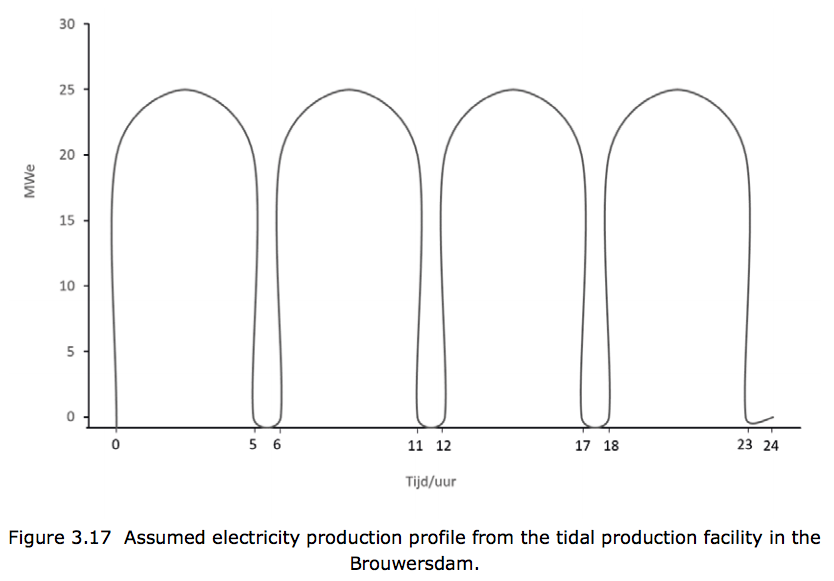

Last month, a heavyweight consortium of local and global companies announced plans to collaborate on a project to design, build, operate, and evaluate a demonstration plant to produce "green ammonia" from water, air, and renewable energy in The Netherlands. This is one practical outcome of last year's Power-to-Ammonia study, which examined the economic and technical feasibility of using tidal power off the island of Goeree-Overflakkee in Zuid-Holland to power a 25 MWe electrolyzer unit, and feed renewable hydrogen to a 20,000 ton per year green ammonia plant. This new demonstration plant phase of the project will still be led by the original developer, Dutch mini-ammonia plant developer Proton Ventures. However, its partners in the venture now include Yara and Siemens, as well as speciality fertilizer producer Van Iperen, and local sustainable agricultural producer, the Van Peperstraten Groep.