Content Related to Nel Hydrogen

Reliance to manufacture Nel electrolysers in India

Nel will license its alkaline electrolyser technology to India-based Reliance Industries which will manufacture them for the Indian market.

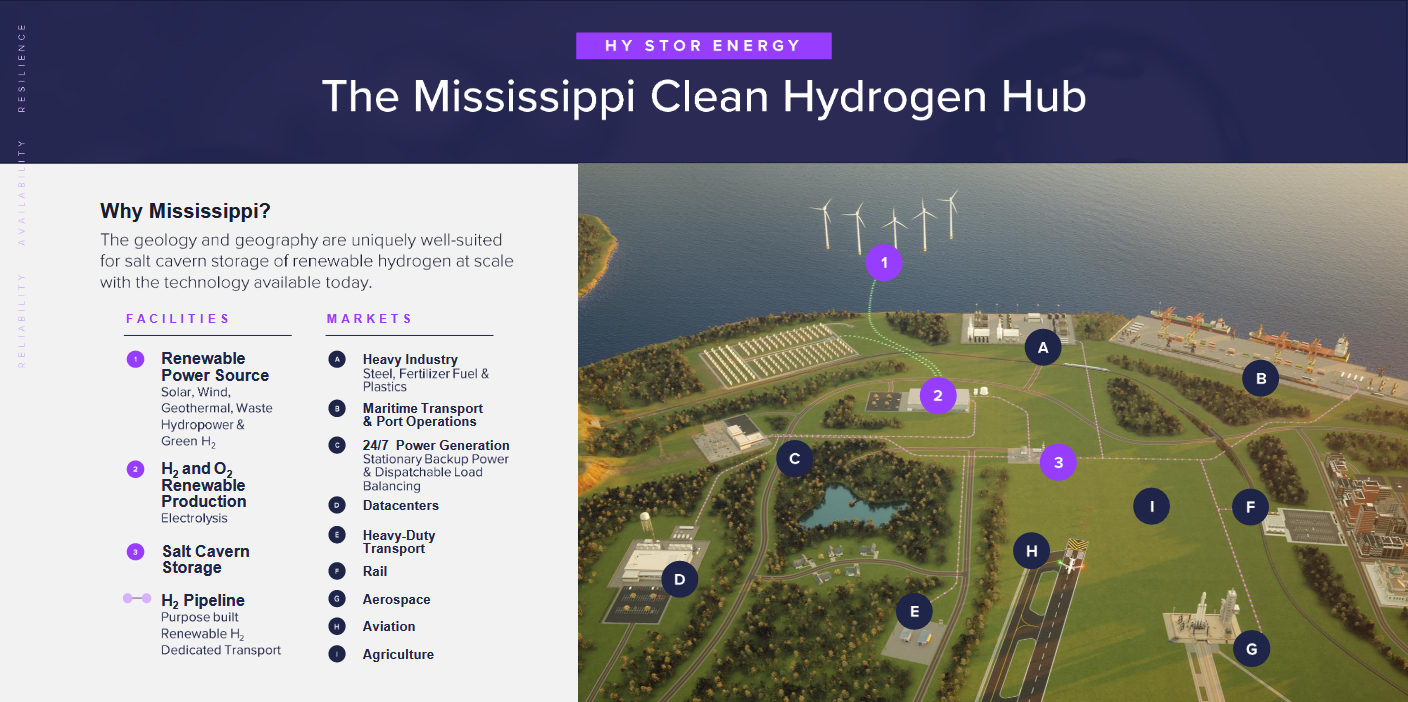

Hy Stor & Nel: electrolyser supply for Mississippi-based renewable hydrogen

Nel will supply over 1 GW of alkaline electrolysers for Hy Stor Energy’s hydrogen production and storage hub project in Mississippi, USA. In other electrolyser news, Cepsa and Allied Green Ammonia have picked technology providers for their under-development projects in Spain and Australia.

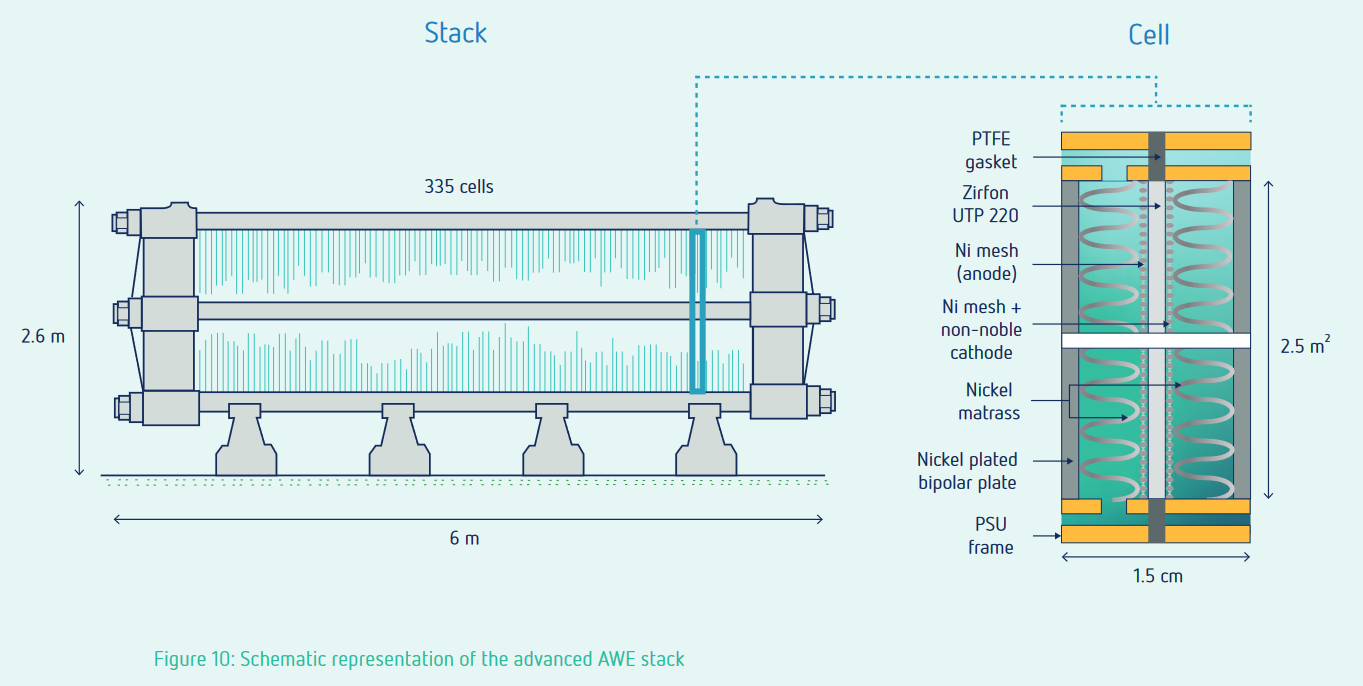

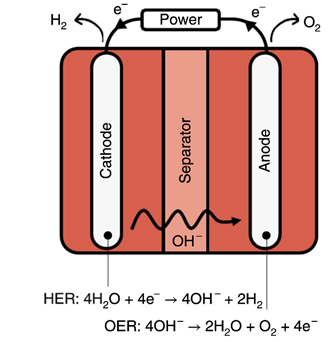

Technology status: alkaline electrolysis for renewable ammonia production

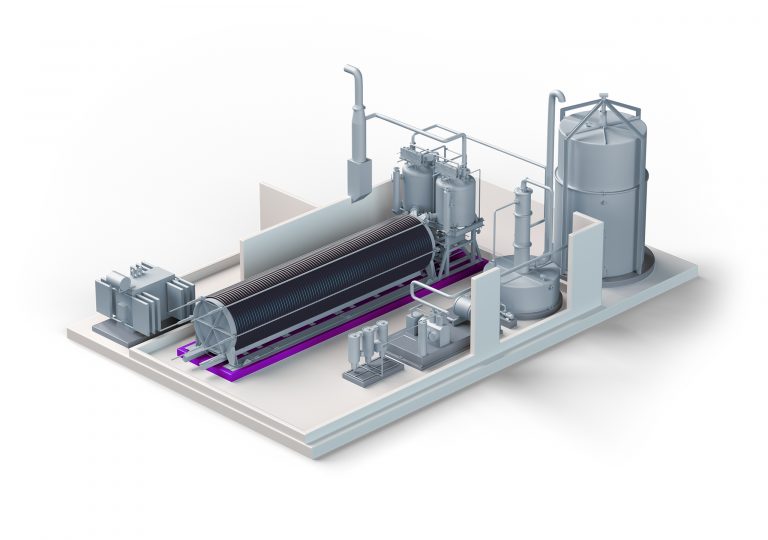

Alkaline electrolyzers will play a significant role in renewable ammonia production going forward. Historical developments in electrocatalysts and optimized stack design have already addressed some of the key bottlenecks in the technology, and new developments will enable flexible operations at higher pressures.

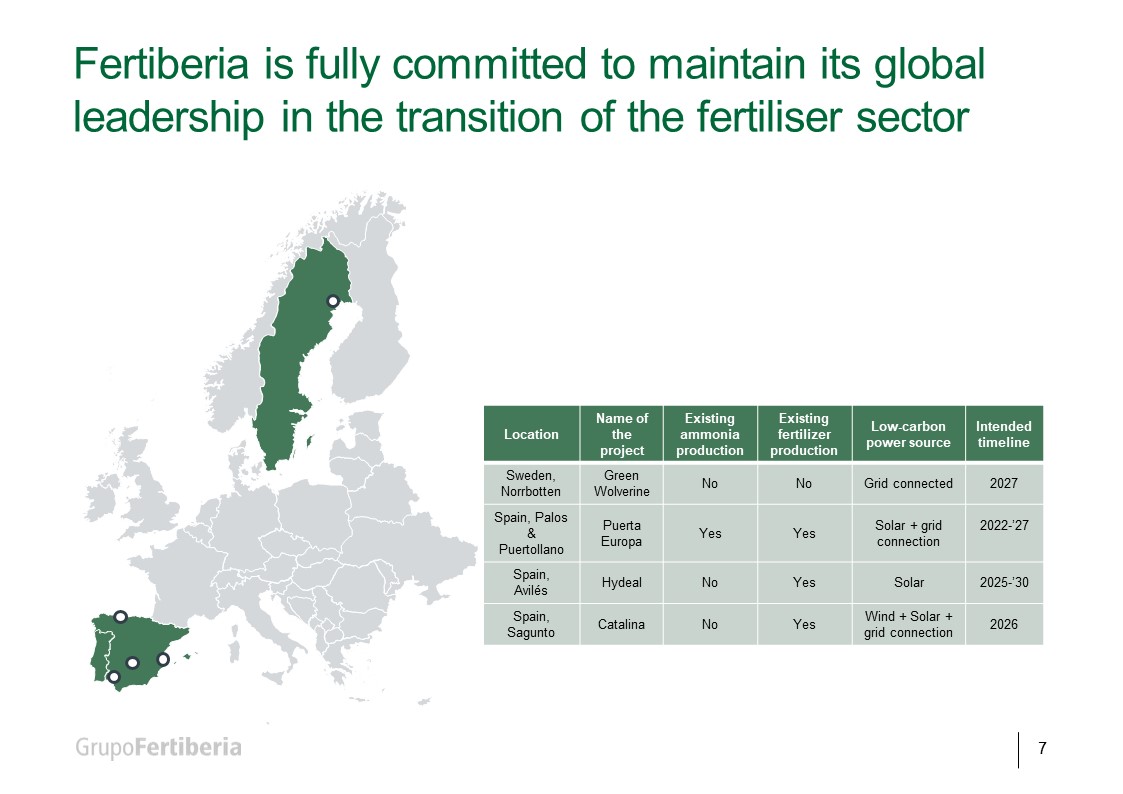

Renewable ammonia: key projects & technologies in the emerging market

For the latest episode of Ammonia Project Features, we explored the ongoing renewable ammonia project in Puertollano, Spain. Marc van Doorn (Grupo Fertiberia) and Imanol Arrizabalaga Prado (Nel ASA) discussed progress to date and technologies used at the first large-scale, electrolysis-based hydrogen facility in Europe, which is operated by renewable energy developer Iberdrola. We also considered what other pioneering projects are on the horizon, and how can electrolyzer manufacturers like Nel scale-up to meet growing demand?

Renewable ammonia in operation: Puertollano, Spain

Fertiberia recently opened its first renewable ammonia production project in Puertollano, with Nel supplying 20 MW of PEM electrolyzer units to produce renewable hydrogen feedstock.

Skovgaard renewable ammonia project orders electrolysers from Nel

The consortium developing the Skovgaard ammonia project has ordered an alkaline electrolyser system from Nel, bringing the 10 MW plant a step closer to reality. Skovgaard will be an important test case for hydrogen production directly from renewable energy, with no battery storage or firming to be used.

In other electrolyser news, German-based Sunfire and US-based Electric Hydrogen have received new funding to develop their technologies. Also in Germany, Siemens and Air Liquide will join forces to develop a GW-sized factory in Berlin, with 3 GW of PEM electrolyser units to be manufactured annually by 2025.

Electrolyser scale-up news: May 2022

This week we explore announcements about novel electrolyser technologies (Advanced Ionics), funding announcements from Europe (ITM Power, Battolyser and Sunfire), and some gigawatt-scale expansions in manufacturing capacities (Hydrogen Optimized, Nel, Cummins and Sinopec).

The Ammonia Wrap: ICE announces its new green ammonia "SuperGiant", Cummins and KBR team up on integrated solutions, a new green ammonia pilot in Minnesota and decarbonisation of existing plants in Russia

Welcome to the Ammonia Wrap: a summary of all the latest announcements, news items and publications about ammonia energy. There's so much news this edition that we're bringing you two, special Wrap articles. Our first focuses on ammonia production - both existing and new build plants. This week: InterContinental Energy to build 25 GW of green ammonia production in Oman, Cummins and KBR to collaborate on integrated green ammonia solutions, New green ammonia pilot plant for Minnesota, Stamicarbon launches new technology for sustainable fertilizer production in Kenya, Haldor Topsoe and Shchekinoazot to explore ammonia plant decarbonisation in Russia, 1 million tonne blue ammonia per year in Norway and Trammo announces off-take MoU for 2GW AustriaEnergy plant in Chile.

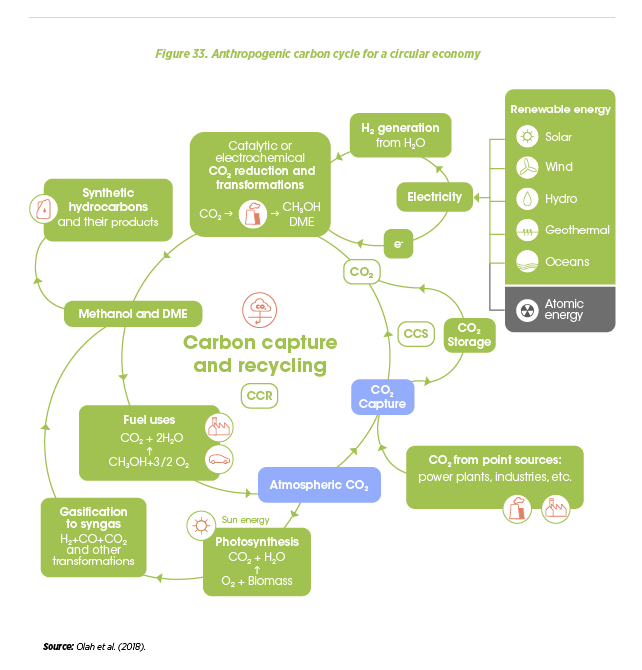

The Emerging Ammonia-Methanol Dialectic

Based on recent press reports, ammonia has a new friend: methanol. With the two upstart fuels being mentioned together with increasing frequency, they seem poised to develop on parallel paths as each seeks market applications where it can become a mainstay solution.

The Ammonia Wrap: India updates, continuous hydrogen production by SOEC, a new zero-emissions shipping company and Port of Rotterdam developments

Welcome to the Ammonia Wrap: a summary of all the latest announcements, news items and publications about ammonia energy. This week: updates from India, the PROMETEO project - continuous hydrogen production by SOEC, Viridis Bulk Carriers - a new zero-emissions shipping company, Korean Register AiP for ammonia bunkering vessel, two green hydrogen import MoUs for the Port of Rotterdam and Haldor Topsoe and Nel team up to offer green fuel solutions.

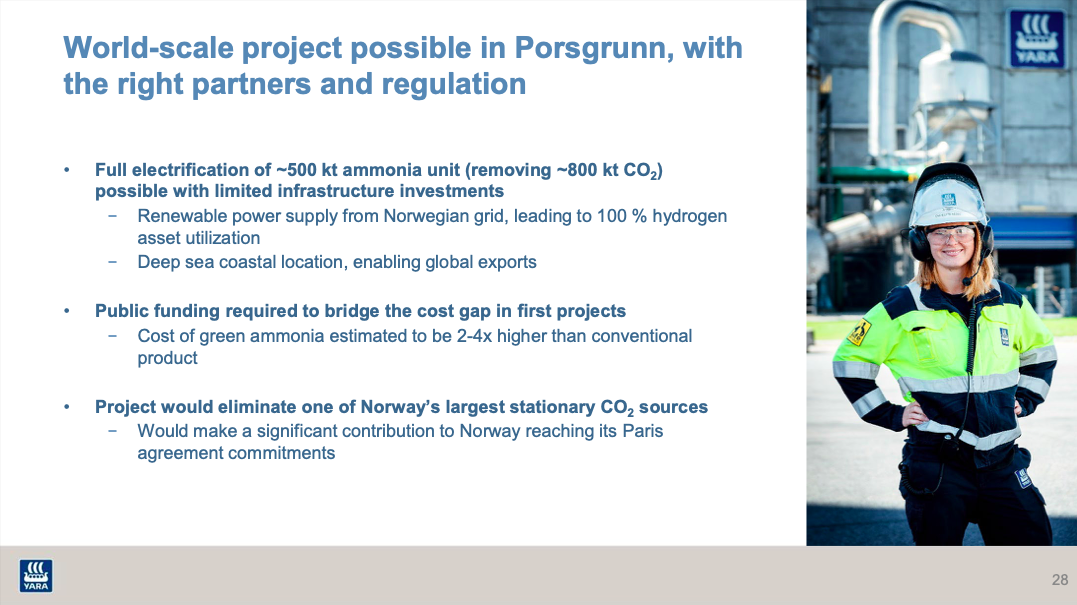

Full electrification: Yara plans 500,000 tons of green ammonia in Norway by 2026

Green ammonia projects continue to be announced at dizzying speed and scale. A few weeks ago, Origin Energy disclosed its feasibility study to develop 500 MW (hydro) / 420,000 tons per year of green ammonia in Tasmania, with first production targeted for mid-2020s. This week, a consortium led by Haldor Topsoe and Vestas announced 10 MW (wind+solar) / 5,000 tons of green ammonia in Denmark, which could be operational in 2022, making it the first green ammonia plant at this scale. Also this week, Yara made a significant corporate announcement, detailing a “transformation of its commercial business models, sales channels and offerings,” with the full decarbonization of its Porsgrunn plant at the heart of its strategy to use green ammonia “to enable the hydrogen economy.”

Europe! (continued)

Last week Ammonia Energy published “Europe!”, an article describing the European Commission’s Green Deal and the related appearance of national hydrogen strategies from several European countries. This week we have an article that describes another consequential European initiative that, while related to the Green Deal, is running on a distinct track: the Clean Hydrogen Alliance. Along the way a clear call to action has been sounded for the ammonia energy community.

Gigawatt-scale electrolyzer manufacturing and deployment

ANNUAL REVIEW 2019: Electrolyzers have featured heavily at this year's Ammonia Energy Conference, which ended today. How much can innovation increase efficiency? How far can volume manufacturing drive down capex? How much could process integration with Haber-Bosch deliver improved ammonia production? How realistically can new, sophisticated strategies optimize variable and baseload power inputs? These technical questions are all important, but none defines profitability. While progress is being made on all these fronts of research and development, major industrial projects are still moving forward.

Israeli Group Develops New Electrolysis Technology

Last month a group of researchers from the Technion Israel Institute of Technology published a paper, “Decoupled hydrogen and oxygen evolution by a two-step electrochemical–chemical cycle for efficient overall water splitting,” in the journal Nature Energy. The key word in the title is “efficient.” In a September 15 Technion press release, the researchers state that their technology “facilitates an unprecedented energetic efficiency of 98.7% in the production of hydrogen from water.” Applied to the appropriate use case, the technology could lead to a major improvement in green ammonia’s ability to compete with brown ammonia and other low-carbon energy carriers.

Green Ammonia Plants in Chile, Australia, New Zealand

Green ammonia plants are being announced quicker than I can report. Here is a summary of four new projects that propose to use electrolyzers, fed by renewable power, to produce hydrogen for ammonia production. These are big companies, operating in regions with excellent renewable resources, making significant investments in their future. In Chile, it is Enaex, a major ammonium nitrate manufacturer, supplying explosives to the mining industry. In Australia, it is Incitec Pivot, "the second largest supplier of explosives products and services in the world," and Wesfarmers, "the largest Australian company by revenue," according to Wikipedia. In New Zealand, it is Ballance-Agri Nutrients, a big farmers' co-operative and the country's sole fertilizer producer. Each aims to make its business "future-proof." The transition from fossil ammonia to renewable ammonia is underway.

Yara and Nel collaborate to reduce electrolyzer costs; announce green ammonia pilot in Norway by 2022

This week, two Norwegian companies, fertilizer producer Yara and electrolyzer manufacturer Nel, announced an agreement to test Nel's "next generation" alkaline electrolyzer at an ammonia production site. The parties expect to begin operating a 5 MW prototype in 2022, feeding green hydrogen directly into Yara's 500,000 ton per year ammonia plant at Porsgrunn.

NH3 Event in Rotterdam, June 6-7

This year's ammonia conference in Rotterdam, the third annual NH3 Event, begins two weeks from today. Since our guest post in March, announcing the initial roster of conference speakers, the organizers have confirmed new speakers, added more sessions, and announced further details. The NH3 Event is a two-day conference, taking place on June 6 & 7, presenting "state of the art solutions and innovations on the subject of Sustainable Ammonia." Although the conference hall is already close to capacity, a few dozen tickets remain available through the NH3 Event website.

Electrolysis for Renewable Ammonia: How do we get to a relevant scale?

This Week in Hydrogen

September 10–14 gave us five remarkable events both evidencing and advancing the rise of hydrogen in transportation and energy. Any one of them would have made it a significant week; together they make a sea change.

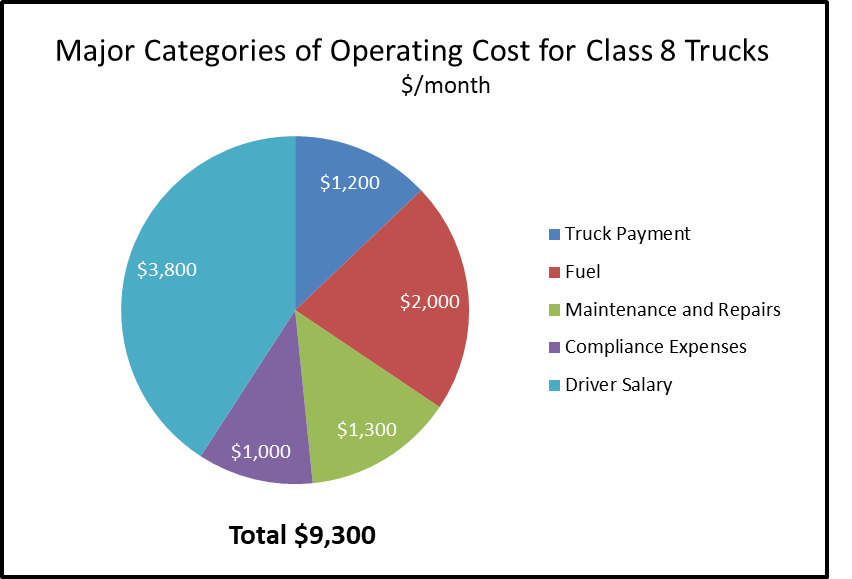

Nel Stakes a Claim on Another Key Frontier of Hydrogen Implementation

On June 28, Norwegian hydrogen company Nel ASA issued a press release announcing that the company will supply “448 electrolyzers and associated fueling equipment to Nikola Motor Company as part of Nikola’s development of a hydrogen station infrastructure in the U.S. for truck and passenger vehicles.” The Nikola-Nel arrangement is a globally significant step in the process of implementing a full-scale hydrogen energy economy. And although its approach for supplying green energy to hydrogen fueling stations does not involve ammonia, it seems likely it will ultimately help make the case for ammonia as an economically advantaged option.

Ammonia Tagged as Storage Medium for Wind Energy

Henrik Stiesdal is a distinguished figure in the field of wind energy. As such, he has had ample occasion to contemplate the field’s challenges and opportunities. Recently he concluded that ammonia may become an important part of wind energy’s future.

Full program announced for the 2018 NH3 Event Europe

The second annual European Conference on Sustainable Ammonia Solutions has announced its full program, spread over two days, May 17 and 18, 2018, at Rotterdam Zoo in the Netherlands. The international cadre of speakers, representing a dozen countries from across Europe as well as the US, Canada, Israel, and Japan, will describe global developments in ammonia energy from the perspectives of industry, academia, and government agencies.

Future Ammonia Technologies: Electrochemical (part 2)

Last week, in Part 1 of this series on electrochemical ammonia synthesis technologies, I quoted a recent article by researchers at MIT that identified avenues for future research and development. One option was a biomimicry approach, learning from "enzymatic catalysts, such as nitrogenases," which can "either be incorporated into or provide inspiration for the design of electrocatalytic processes." The nitrogenase enzyme, nature's ammonia synthesis technology, was developed in an iterative innovation process, otherwise known as evolution, that took hundreds of millions of years to reach this level of efficiency. According to one group of electrochemists, who presented their results at the recent NH3 Energy+ conference, nitrogenase produces ammonia in nature with an enviable 75% process efficiency - so it's no surprise that they are basing their industrial technology on it.

Renewable Hydrogen in Fukushima and a Bridge to the Future

On August 1, 2017 the Japan Government’s New Energy and Industrial Technology Development Organization (NEDO) announced that it will proceed with funding for the construction of a hydrogen production plant in Namie Township, about ten kilometers from the site of the Fukushima nuclear disaster. The project’s budget is not mentioned, but the installation is projected to be “the largest scale in the world” -- in other words, a real bridge to the future and not a demonstration project. The project no doubt has a variety of motivations, not least the symbolic value of a renewable hydrogen plant rising in the shadow of the Fukushima Daiichi nuclear station. In economic terms, though, it appears to be a dead end. This is unfortunate because a similarly conceived project based on ammonia could be a true bridge-building step that aligns with leading-edge developments elsewhere in the world.

NH3 Fuel Association Announces Charter Sponsors

The NH3 Fuel Association (NH3FA) has released the names of the organization’s charter group of sponsors. The common thread that unites the six companies? A conviction that ammonia energy represents a significant opportunity for their businesses. The sponsors are Yara, Nel Hydrogen, Airgas, Haldor Topsoe, Casale, and Terrestrial Energy.

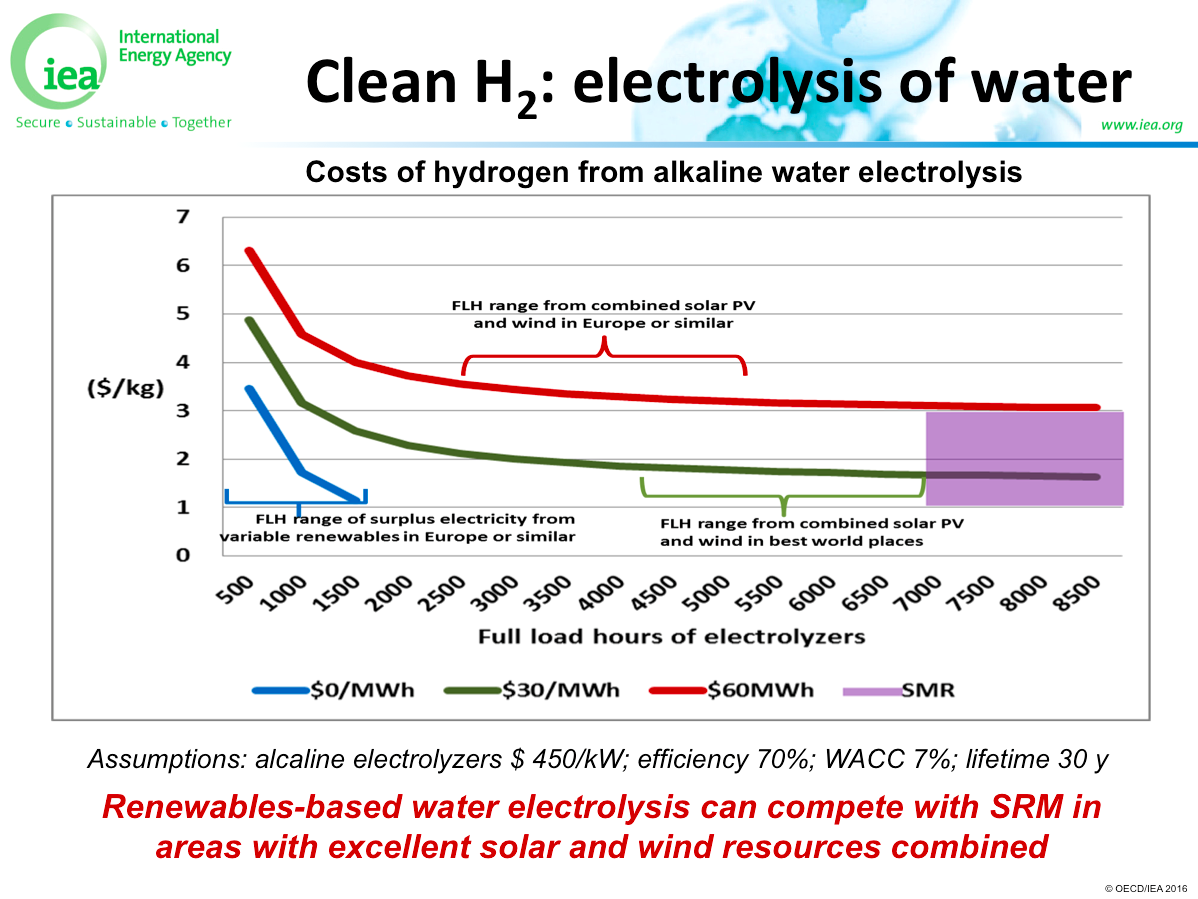

Report from the European Conference: Renewable Ammonia cost-competitive with Natural Gas Ammonia

The viability of producing ammonia using renewable energy was one of the recurring themes of the recent Power to Ammonia conference in Rotterdam. Specifically, what cost reductions or market mechanisms would be necessary so that renewable ammonia - produced using electrolytic hydrogen in a Haber-Bosch plant - would be competitive with normal, "brown" ammonia, made from fossil fuels. A number of major industry participants addressed this theme at the conference, including Yara and OCI Nitrogen, but it was the closing speech, from the International Energy Agency (IEA), that provided the key data to demonstrate that, because costs have already come down so far, renewable ammonia is cost-competitive in certain regions today.

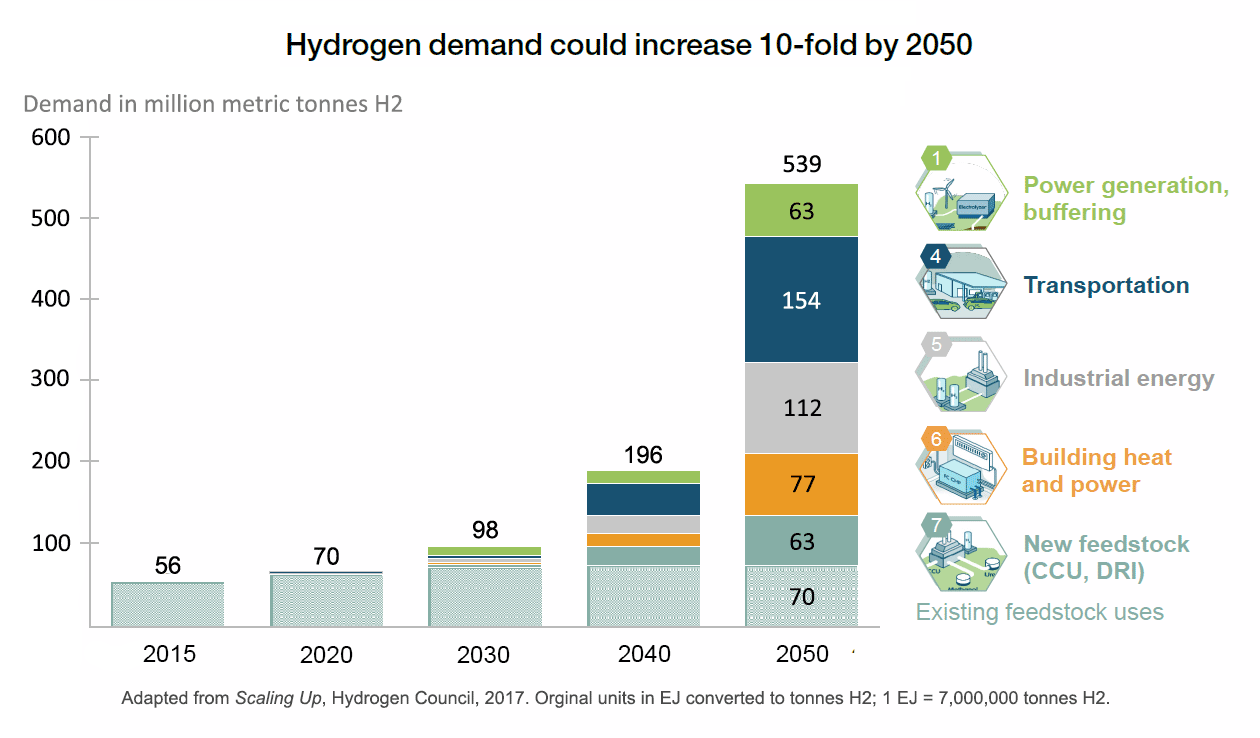

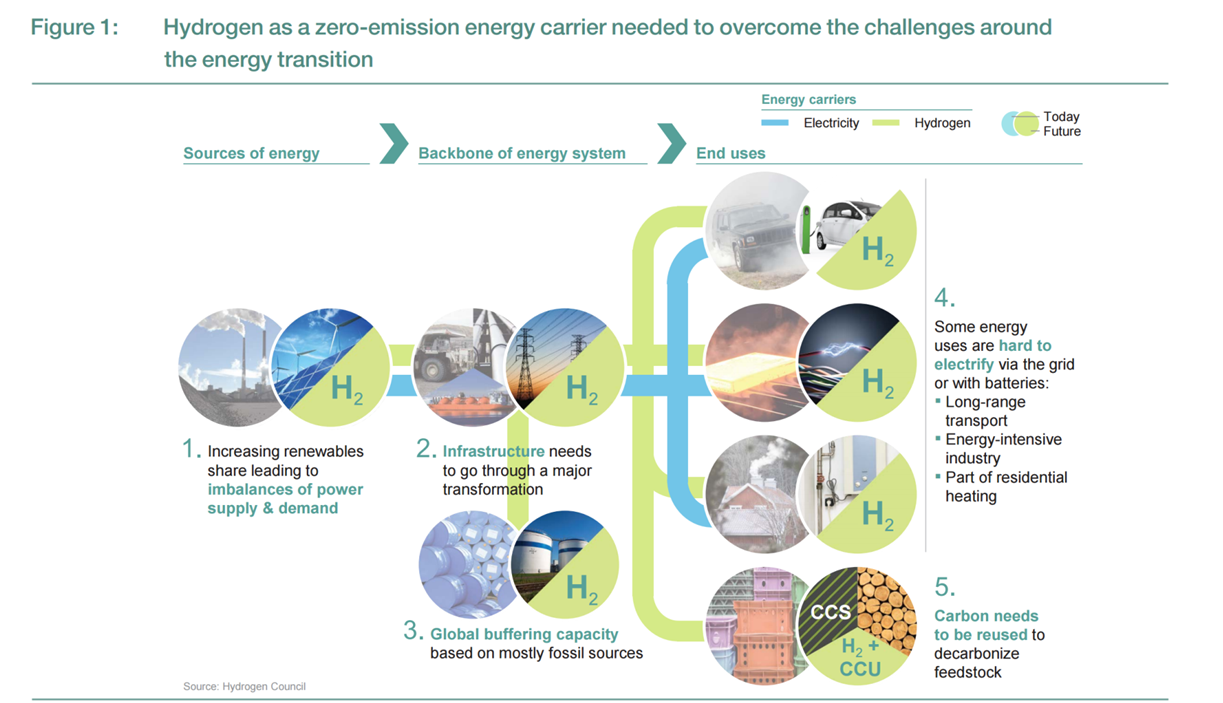

The Hydrogen Consensus

Let’s say there is such a thing as the “hydrogen consensus.” Most fundamentally, the consensus holds that hydrogen will be at the center of the sustainable energy economy of the future. By definition, hydrogen from fossil fuels will be off the table. Hydrogen from biomass will be on the table but the amount that can be derived sustainably will be limited by finite resources like land and water. This will leave a yawning gap (in the U.S., 60-70% of total energy consumption) that will be filled with the major renewables -- wind, solar, and geothermal -- and nuclear energy. This may be as far as the consensus goes today, but more detail is now emerging on the global system of production and use that could animate a hydrogen economy.

IEA calls for renewable hydrogen and carbon-free ammonia

This week, an important new voice joined the chorus of support for renewable ammonia and its potential use as an energy vector - the International Energy Agency (IEA). In his article, Producing industrial hydrogen from renewable energy, Cédric Philibert, Senior Energy Analyst at the IEA, identifies a major problem with the hydrogen economy: hydrogen is currently made from fossil fuels. But his argument for producing hydrogen from renewable energy leads almost inevitably to ammonia: "In some not-too-distant future, ammonia could be used on its own as a carbon-free fuel or as an energy carrier to store and transport energy conveniently."