Australia-based Aviation H2 have selected the use of liquid ammonia to turbofan combustion as the best pathway forward for developing hydrogen-powered aircraft. Based on the existing Dassault Falcon 50, Aviation H2 aims to have the converted aircraft in the skies by mid-2023.

Content Related to Reaction Engines

Article

New UK joint venture for lightweight, modular ammonia crackers

Julian Atchison November 10, 2021

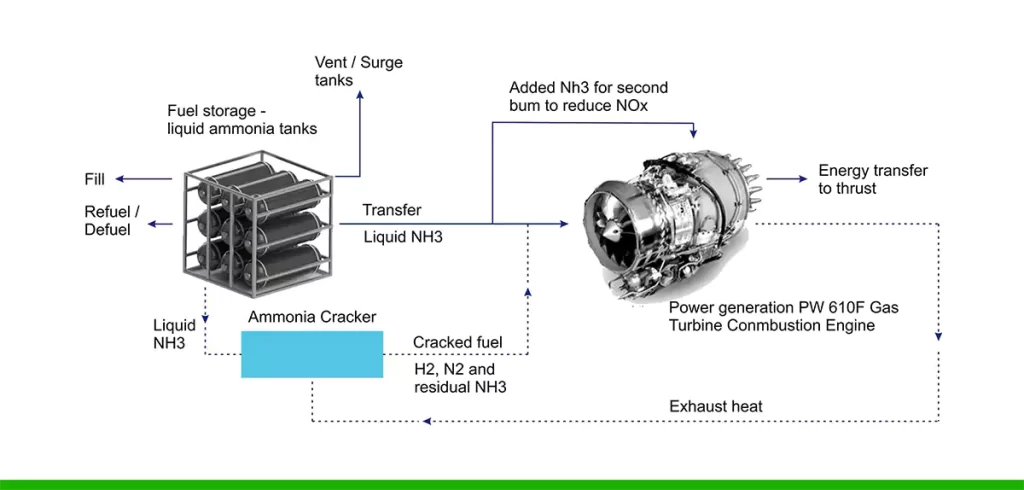

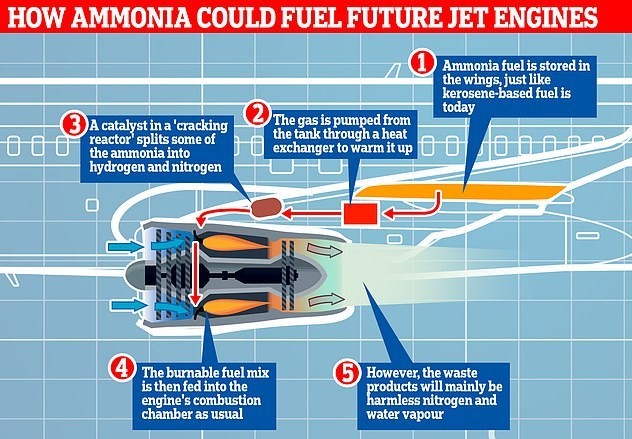

Reaction Engines, IP Group, and the Science and Technology Facilities Council (STFC) launched a new joint venture this week at COP26 in Glasgow. The group will design and commercialise lightweight, modular ammonia cracking reactors to enable the use of ammonia in hard-to-decarbonise sectors, particularly aviation, shipping and off-grid power generation applications. The design will feature Reaction Engines’ heat exchanger technology developed for its SABRE™ air-breathing rocket engine. In this setup, exhaust heat is utilised to partially crack ammonia back into a fuel blend that "mimics" jet fuel. STFC will lead development of the cracking catalyst, with funding to be provided by IP Group.

Article

Zero emission aircraft: ammonia for aviation

Trevor Brown August 20, 2020

This week, Reaction Engines announced a “ground-breaking study” on ammonia as a fuel for zero-emission aircraft. This will soon be followed by a demonstration project, “integrating the technology into a ground-based test engine.” The study combines Reaction Engines’ heat exchanger technology with the ammonia cracking technology being developed by the UK’s Science and Technology Facilities Council (STFC). By partially cracking green ammonia to hydrogen, the resulting ammonia fuel mix “mimics jet fuel,” making it possible to adapt existing engines and aircraft to use zero-emission fuels. “This means a fast transition to a sustainable aviation future is possible at low cost.”