The Ammonia Synthesis Plant from Intermittent Renewable Energy (ASPIRE) project is now online outside of Oxford, UK. The demonstrator will produce 300kg per day of renewable ammonia via a containerized, modular system.

Content Related to Science and Technology Facilities Council (STFC)

Presentation

Sunborne reborn!

Despite successfully demonstrating 56kW of controlled combustion of partially cracked ammonia in October 2023, Sunborne Systems was unable to secure Series A funding at the beginning of 2024. Since then, the co-founders have secured UK government funding to tackle two of the challenges set out for Series A funding: to further develop their patented catalysts and to address issues associated with ammonia slippage and NOx emissions. Future opportunities will be discussed.

Article

R&D recap: the Journal of Ammonia Energy – volume II

Geofrey Njovu August 13, 2024

Ahead of the international Symposium on Ammonia Energy event next month, we recap R&D presented in the second edition of the Journal on Ammonia Energy:

- An integrated, indirect ammonia solid-oxide cell featuring a heat exchanger and ammonia cracker was modelled, built and tested by the UK’s Science and Technologies Council (STFC).

- The techno-economics of the transportation of energy from Orkney, Scotland to Milford Haven, Wales using ammonia as an energy carrier transported by ship may be the most cost-effective option.

- N2O and NOX conversion in ammonia engine exhausts is limited by the presence of oxygen and water, presenting an optimisation challenge for technology developers.

- And an academic-industry joint session on ammonia safety highlighted multiple projects currently underway to tackle the risks associated with the use of ammonia in new commercial sectors.

Article

Government funding for ammonia energy in the UK

Julian Atchison May 26, 2022

The Department for Business, Energy and Industrial Strategy (BEIS) will contribute to three ammonia energy projects via the latest funding round of its Net Zero Innovation Portfolio:

- The Tyseley Ammonia to Green Hydrogen Project near Birmingham, where a demonstration ammonia cracking unit based on H2SITE’s technology will be built to deliver hydrogen transportation fuel.

- The GreeNH3 project from Supercritical, ScottishPower and Proton Ventures to develop a renewable ammonia pilot plant based on Supercritical’s new electrolyser technology.

- And the Ammonia Synthesis Plant from Intermittent Renewable Energy (ASPIRE) project. Partners the Science and Technology Facilities Council (STFC) and Frazer-Nash Consultancy are developing autonomous renewable ammonia production plants in the UK.

Article

New UK joint venture for lightweight, modular ammonia crackers

Julian Atchison November 10, 2021

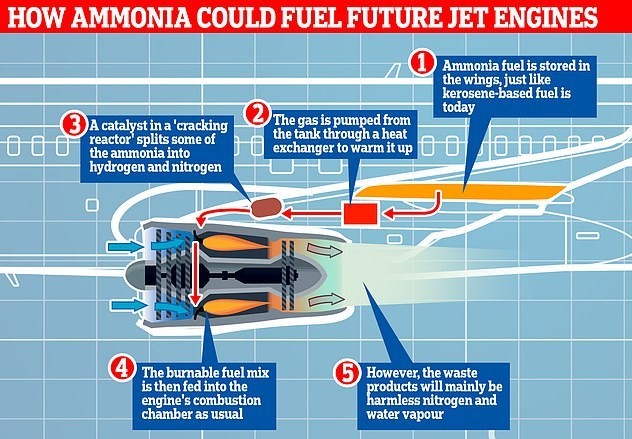

Reaction Engines, IP Group, and the Science and Technology Facilities Council (STFC) launched a new joint venture this week at COP26 in Glasgow. The group will design and commercialise lightweight, modular ammonia cracking reactors to enable the use of ammonia in hard-to-decarbonise sectors, particularly aviation, shipping and off-grid power generation applications. The design will feature Reaction Engines’ heat exchanger technology developed for its SABRE™ air-breathing rocket engine. In this setup, exhaust heat is utilised to partially crack ammonia back into a fuel blend that "mimics" jet fuel. STFC will lead development of the cracking catalyst, with funding to be provided by IP Group.

Article

Cracking Ammonia: panel wrap-up from the Ammonia Energy Conference

Julian Atchison February 19, 2021

When should we be cracking ammonia? How much should we be cracking? How could better cracking technologies open up new end uses? What are the critical challenges still to be overcome for cracking ammonia? On November 17, 2020, the Ammonia Energy Association (AEA) hosted a panel discussion moderated by Bill David from Science and Technology Facilities Council (STFC), as well as panel members Josh Makepeace from the University of Birmingham, Joe Beach from Starfire Energy, Gennadi Finkelshtain from GenCell Energy, Camel Makhloufi from ENGIE, and Michael Dolan from Fortescue as part of the recent Ammonia Energy Conference. All panelists agreed that cracking technology as it stands has a number of key areas to be optimised, particularly catalyst improvements and energy efficiency. But, successful demonstrations of modular, targeted cracking solutions are accelerating the conversation forward.

Article

Zero emission aircraft: ammonia for aviation

Trevor Brown August 20, 2020

This week, Reaction Engines announced a “ground-breaking study” on ammonia as a fuel for zero-emission aircraft. This will soon be followed by a demonstration project, “integrating the technology into a ground-based test engine.” The study combines Reaction Engines’ heat exchanger technology with the ammonia cracking technology being developed by the UK’s Science and Technology Facilities Council (STFC). By partially cracking green ammonia to hydrogen, the resulting ammonia fuel mix “mimics jet fuel,” making it possible to adapt existing engines and aircraft to use zero-emission fuels. “This means a fast transition to a sustainable aviation future is possible at low cost.”

Article

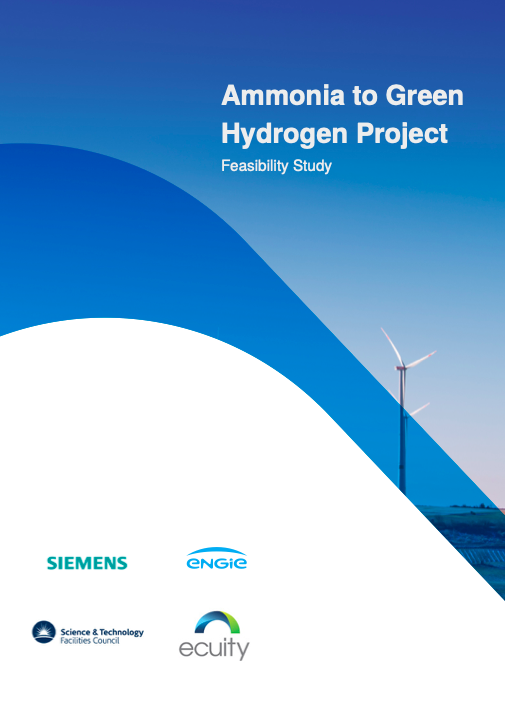

Engie, Siemens, Ecuity, and STFC publish Feasibility of Ammonia-to-Hydrogen

Trevor Brown June 18, 2020

The UK’s Department for Business, Energy and Industrial Strategy (BEIS) recently published the feasibility study for its Ammonia to Green Hydrogen Project. This studies the techno-economic feasibility of importing green ammonia in order to supply large volumes of high-purity low-carbon hydrogen in the UK. The project has been designed and delivered by a heavyweight consortium of ENGIE, Siemens, Ecuity Consulting, and the UK’s STFC. The feasibility study, which is publicly available, represents the conclusion of Phase One of this project. Phase Two is demonstration: “to raise the TRL of a lithium imide based ammonia cracker from 4 to 6/7,” meaning that the technology is ready for deployment.

Article

Engie, Siemens, STFC, and Ecuity awarded funding for green ammonia-to-hydrogen in UK

Trevor Brown September 06, 2019

Last week, the UK Department for Business, Energy and Industrial Strategy (BEIS) announced a "£390 million government investment to reduce emissions from industry," with a focus on low-carbon hydrogen supply and clean steel production. As part of this investment, a consortium led by Ecuity Consulting that includes Siemens, Engie, and the Science & Technology Facilities Council (STFC), has been awarded £249,000 to perform "valuable research on the role of ammonia in the delivery of low cost bulk hydrogen for use in the UK energy system."

Article

254th ACS Meeting, Energy and Fuels Symposium “The Ammonia Economy” — Oxidation, Catalytic Cracking & Storage

Martin Owen Jones October 31, 2017

In August of 2017 a symposium on the Ammonia Economy was held in Washington DC as part of the Energy and Fuels Division of the American Chemical Society (ACS) conference. The symposium was devised to explore the latest results from ammonia related research, including but not limited to; advances in the generation of ammonia, advances in the catalytic cracking of ammonia to nitrogen and hydrogen, ammonia storage and utilisation, detectors and sensors for ammonia, ammonia fuel cells and hydrogen from ammonia, ammonia combustion and ammonia safety.

Article

254th ACS Meeting, Energy and Fuels Symposium “The Ammonia Economy” — Synthesis, Utilization & Nitrogen Reduction

Michael Mock October 31, 2017

In late August, the day before the exciting solar eclipse, the Ammonia Economy symposium was held as part of the Energy and Fuels Division of the American Chemical Society (ACS) National Meeting in Washington DC. This marks the third gathering of Ammonia related research since 2015 at the national level ACS conference. This year, in addition to the important focus on chemistries for the utilization of ammonia, the rapidly developing field of homogeneous catalysts and biological processes for nitrogen fixation was included as a major theme.

Article

The Ammonia Economy at the ACS National Meeting

Trevor Brown July 06, 2017

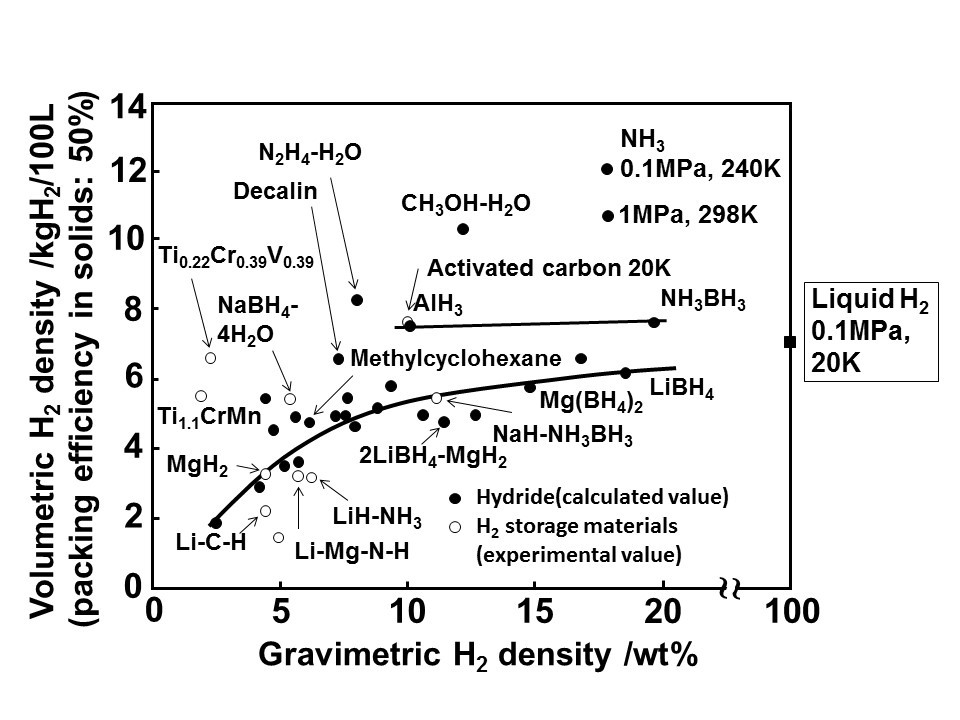

The American Chemical Society (ACS) has published the program for its 2017 National Meeting, which takes place next month in Washington DC and includes a session dedicated to the "Ammonia Economy." The first day of the week-long meeting, Sunday August 20th, will feature a full morning of technical papers from the US, UK, and Japan, covering ammonia energy topics across three general areas: producing hydrogen from ammonia, developing new catalysts for ammonia synthesis and oxidation, and storing ammonia in solid chemical form.

Presentation

Investigating and Understanding Ionic Ammine Materials

Ammonia has been promoted as a viable candidate as an indirect hydrogen fuel vector, due to its high hydrogen content (17.8 wt%) and its ability to store 30% more energy per liquid volume than liquid hydrogen [1]. Ammonia can be safely stored in very high gravimetric and volumetric density in solid state halide materials [2-3], for example, at 109 gL-1 for Mg(NH3)6Cl2 compared to 108 gL-1 for liquid ammonia. These solid state ammonia coordination complexes, known as ammines, have attracted much recent attention (for examples see [4-5] and references there within) with a view to their use as solid state…