Presentation

Ammonia Production Can be Practically Free

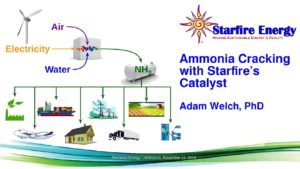

As a prototype I take Green ammonia: Haldor Topsoe’s solid oxide electrolyzer ( https://ammoniaenergy.org/green-ammonia-haldor-topsoes-solid-oxide-electrolyzer/ ) to produce synthesis-gas (1/2 N2 + 1.5 H2 ) for ammonia production from air, water and renewable energy. The big disadvantage of it is very expensive CAPEX of the electrolyzer consuming 7.2 MWh electricity per a ton of ammonia. In my turn, I suppose a following technology consuming 7.0-7.4 MWh electricity to produce ammonia with by-product of 0.4 ton formaldehyde solution (40% in water) being now USD 300-350/ton fob price, considered as that ammonia payback including CAPEX. The world annual consume of formaldehyde exceeds 10…