REFUEL Ammonia Use-Side Funding Awards

By Stephen H. Crolius on December 23, 2016

Six of the projects designated for funding by the U.S. Department of Energy’s ARPA-E REFUEL announcement on December 15 involve technologies on the use side of the ammonia energy space. Three focus on generating hydrogen from ammonia. Two focus on fuel cells that convert ammonia to electricity. One project involves both ammonia synthesis and use.

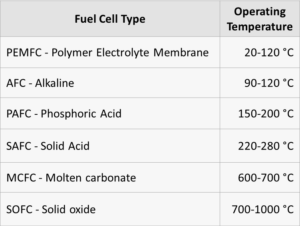

The use-side project with the largest award is “Distributed Electrochemical Production and Conversion of Carbon-Neutral Ammonia”, proposed by SAFCell, Inc. of Pasadena, CA. The award is for $3 million. The goal of the project team is to develop a “distributed system” that can “greatly simplify . . . the infrastructure required to get hydrogen fuel to refueling stations and store it there.” The central technology is a “solid acid stack” that will operate at 250 °C and will both generate hydrogen and compress it to the pressure needed to dispense it. The stack is expected to feature “low cost, long-life, [and] a quick start-up time.” The company’s partners for the project will include Northwestern University and LiOX Inc. SAFCell’s founder has a PhD from the California Institute of Technology. The company’s Web site states it has 12 employees. SAFCell received an award of $3.7 million in 2014 from ARPA-E’s Reliable Electricity Based on Electrochemical Systems (REBELS) Program for its “Solid Acid Fuel Cell Stack for Distributed Generation Applications” project. (See the company’s press release.)

The University of South Carolina will receive $1.6 million for its project entitled “A Novel Hollow Fiber Membrane Reactor for High Purity Hydrogen Generation from Thermal Catalytic Ammonia Decomposition.” The reactor’s hollow fibers have been developed to enable reduced catalyst loadings and lower operating temperatures. The reactor will be configurable to serve either as an on-board hydrogen-supply device or in a stationary refueling setting. The South Carolina team is led by Dr. Miao Yu, of the University’s Catalysis for Renewable Fuels Center in the Department of Chemical Engineering. Yu’s group received an award of $3.2 million in 2014 from ARPA-E’s REBELS Program for its “Novel Intermediate-Temperature Bi-functional Ceramic Fuel Cell Energy System” project.

The Bettergy Corporation of Peekskill, NY will receive an award of $1.5 million for a low-temperature ammonia cracking system. The system involves a non-precious-metal catalyst that is effective at temperatures below 450 °C. Hydrogen purification is achieved via a selective membrane. The system is intended for use in hydrogen refueling stations. On its Web site, the company’s cites “novel membrane technologies” among its core technological strengths. Bettergy’s founder, Dr. Lin-Feng Li, has a background in high-tech start-ups. The company’s staff includes eight PhDs as well as “additional technical and administrative staff and several consultants.” Bettergy received at least two Small Business Innovation Research SBIR awards in 2016 from the U.S. Department of Defense related to its high-performance battery technology. (See Bettergy’s News Page.)

The University of Delaware will receive an award of $2.5 million for its “Direct Ammonia Fuel Cells for Transport Applications” project. This is the larger of the two fuel cell awards. The heart of the Delaware concept is a membrane electrolyte that is similar to that used in proton-exchange membrane (PEM) fuel cells, except that it conducts hydroxide (OH-) ions instead of protons. PEM fuel cells operate at close to ambient temperatures which makes them the technology of choice for fuel-cell vehicles. The hydroxide-exchange technology targeted by the Delaware team is expected to operate at 100 °C. Names of University of Delaware team members were not included in the ARPA-E announcement, but Dr. Yushan Yan, Professor of Chemical and Biochemical Engineering, is identified as a lead proponent in another ARPA-E award received in 2016 by the University. This award was for $1.8 million from ARPA-E’s Integration and Optimization of Novel Ion-Conducting Solids (IONICS) program. According to the ARPA-E Web site, IONICS projects “will work to improve energy storage and conversion technologies in transportation batteries, grid-level storage, and fuel cells.” The Delaware project receiving the award is entitled “Highly Conductive, Stable and Robust Hydroxide Exchange Membranes Based on Poly (Aryl Piperidinium).”

The smallest award on the use side — $1.1 million – will go to Materials and Systems Research, Inc. (MSRI), of Salt Lake City. Given the size of the award, it is notable that MSRI intends to enter the relatively crowded solid oxide fuel cell (SOFC) space with an ambitious objective: to “greatly reduce the cost of solid oxide fuel cells while providing a high-efficiency, long-life power generating option.” The targeted technology is an intermediate-temperature platform that will operate at temperatures under 650 °C. MSRI’s co-founders are faculty members of the University of Utah’s Materials Science and Engineering Department. The company’s Web site lists a staff of nine (including the co-founders). The company received an award of $2.8 million in 2014 under ARPA-E’s REBELS Program for a project entitled “Intermediate-Temperature Electrogenerative Cells for Flexible Cogeneration of Power and Liquid Fuel.”

One additional project involves an electrochemical device that will be able to work on a “reversible” basis, both synthesizing ammonia from nitrogen and water, and using stored ammonia to generate electricity. The project, “Protonic Ceramics for Energy Storage and Electricity Generation with Ammonia”, proposed by FuelCell Energy of Danbury, CT, drew the second largest award at $3.1 million. The heart of the technology is an electrode that incorporates ruthenium catalyst. As notable as the device’s reversible nature is, an additional goal is just as striking: an increase in ammonia production rates by two orders of magnitude vs. “current electrochemical methods”. FuelCell Energy is one of the United States’ oldest companies in the fuel cell space. It was founded in 1969 and installed its first “commercial power plant”, consisting of a 250 kW fuel cell stack, in 2003. Earlier this year, the company completed installation of a 5.6 MW plant. In October the company announced that it would enter into a $3.0 million cost-share contract with the U.S. Department of Energy for a technology that “affordably and efficiently converts power during periods of low demand into hydrogen, an energy carrier, through high efficiency electrolysis using solid oxide electrolysis cells.”

This story was updated on January 13, 2017 to correct the misidentification of the Principal Investigator for the University of South Carolina’s “A Novel Hollow Fiber Membrane Reactor for High Purity Hydrogen Generation from Thermal Catalytic Ammonia Decomposition” project.