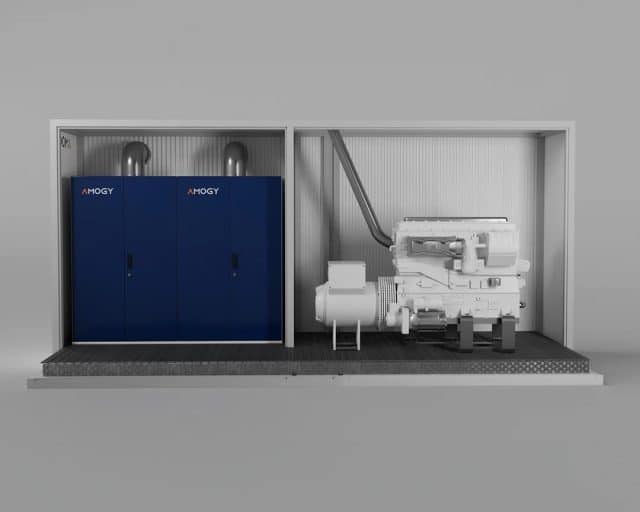

Amogy & Samsung Heavy Industries: new partnership for ammonia-to-power systems manufacturing in South Korea

A new multi-year partnership between the two parties will see Samsung Heavy Industries manufacture Amogy’s ammonia-to-power systems in South Korea for distributed clean energy generation based on ammonia-cracking technology.