Kepco and the Hydrogen Utility have signed an offtake agreement for renewable ammonia produced at the under-development H2-Hub in Gladstone, Queensland. The pair will develop supply chains for the ammonia product to be exported to Korea, where it will be used to decarbonise power stations. In Western Australia, two new renewable energy-powered, million-tonne-per-year projects have been launched, with Korean-based KOMIPO and Australia-based Progressive Green Solutions agreeing to develop the new export plants.

South Korea

Ammonia cracking to enable hydrogen-fueled power generation in South Korea

Johnson Matthey and Doosan Enerbility will develop hydrogen-fueled, closed cycle gas turbine power plants in South Korea. Johnson Matthey will provide cracking technology and catalysts to convert ammonia into pure hydrogen fuel, while Doosan is currently developing a 380 MW, 100% hydrogen fed gas turbine, which will reportedly be complete by 2027. The two will work together to integrate cracking & CCGT technologies, potentially providing a blueprint for similar power plants in the future.

ACWA Power: ammonia partnerships in Korea and South Africa

Saudi-based ACWA Power has signed agreements to explore the overseas production of hydrogen & ammonia with two organisations: South Korean power utility KEPCO, and government-owned finance body the Industrial Development Corporation of South Africa.

Building a renewable ammonia supply chain between Australia and Korea

Korea Zinc, Hanwha Impact, SK Gas and Australia-based Ark Energy will work together to build a million-tonne-per-year renewable ammonia supply chain between Korea and Australia by 2032. Ark Energy’s renewable energy portfolio in Queensland will be leveraged for ammonia production, with the three South Korean organisations acting as offtakers. The announcement comes as the Qld state government launches an ambitious new energy plan, which will support the addition of 20-plus GW of renewable energy generation to Qld’s grid.

Ammonia combustion for power generation: updates from Korea, Malaysia and Singapore

Joint venture SK Plug Hyverse has agreed to deploy its Korean-manufactured PEM electrolysers overseas, and then supply Korea South-East Power (KOEN) with renewable hydrogen & ammonia imports for co-firing at natural gas and coal power plants. In Malaysia, power utility Tenaga Nasional Bhd, IHI Power Systems and Petronas announced they have successfully conducted 60% ammonia co-combustion trials. And in Singapore, Jurong Port, Mitsubishi Heavy Industries and JERA will conduct a joint study on Jurong Island, where a 60MW, combined-cycle gas turbine will be fueled by 100% ammonia to produce zero-carbon electricity.

Syzygy & LOTTE join forces to deploy cracking tech in South Korea

Syzygy Plasmonics, LOTTE and Sumitomo Corporation of Americas announced they will join forces to deploy & test Syzygy’s fully-electric, photocatalytic ammonia cracking reactor at LOTTE Chemical’s HQ in Ulsan, South Korea. Syzygy’s reactor technology uses light from ultra-high-efficiency LEDs to crack ammonia into zero-carbon hydrogen, eliminating combustion emissions usually associated with chemical manufacturing. The announcement is one of several new ammonia collaborations this week, with LOTTE, ITOCHU and Sasol all announcing new agreements.

ACWA Power and POSCO join forces on ammonia

Saudi-based ACWA Power and South Korean-based POSCO will join forces to develop new hydrogen and ammonia production projects, with an eye towards decarbonising POSCO’s power generation and steel making activities in South Korea. The pair are already significant players in the ammonia energy space, with POSCO setting ambitious goals for production & imports, and ACWA involved in multiple mega-projects in the Middle East.

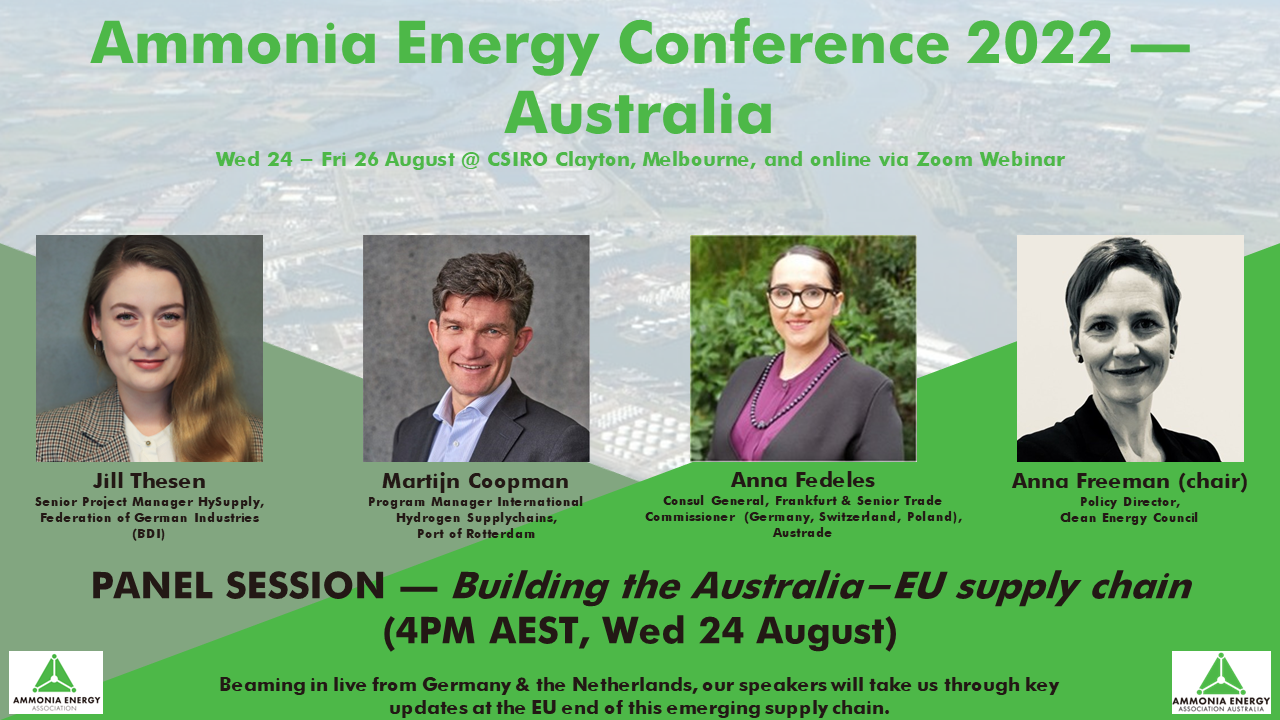

Building the EU end of the Australia-Europe supply chain

At this year’s Australia conference, we recognise that interest in Australian ammonia is on the rise. At previous conferences we’ve witnessed the strengthening of ties between Australia, Japan and South Korea, and this year we see a new player emerge. The EU’s growing ambitions have catapulted it into the ammonia conversation, and the nascent of an Australia-Europe ammonia supply chain is quickly developing. To give our audience the EU-perspective, we welcome a terrific virtual panel beaming in live from the Netherlands, Germany and Italy: Jill Thesen (Federation of German Industries), Martijn Coopman (Port of Rotterdam), Anna Fedeles (Austrade) and Anna Freeman (Clean Energy Council). Join us in-person or online, and make sure to register by the end of this week (Friday 29 July) to secure the early-bird rate.

Dual-fuel ammonia for power generation in South Korea

Doosan, KEPCO and Samsung will join forces to jointly develop a “dual-fuel green ammonia” power generation model that can be rolled out to 1 GW power plants in South Korea. In the trio, Doosan is charged with the development of ammonia dual-fuel boilers, indicating that coal co-firing is the target of the model rollout. As part of a different agreement, Doosan is also involved in ammonia-hydrogen gas turbine development with POSCO and KEPCO.