Ammonia vessel updates: the Castor Initiative, MS Green Ammonia & post-Panamax bulkers

Five ammonia vessel updates this week:

1. An ammonia/liquefied CO2 carrier concept design from Mitsui O.S.K. Lines & Mitsubishi Heavy Industries.

2. Approval in Principle for an ammonia-fueled car carrier designed by China State Shipbuilding.

3. Approval in Principle for the MS Green Ammonia.

4. An MoU between three members of the Castor Initiative to design & construct two Very Large Crude Carriers.

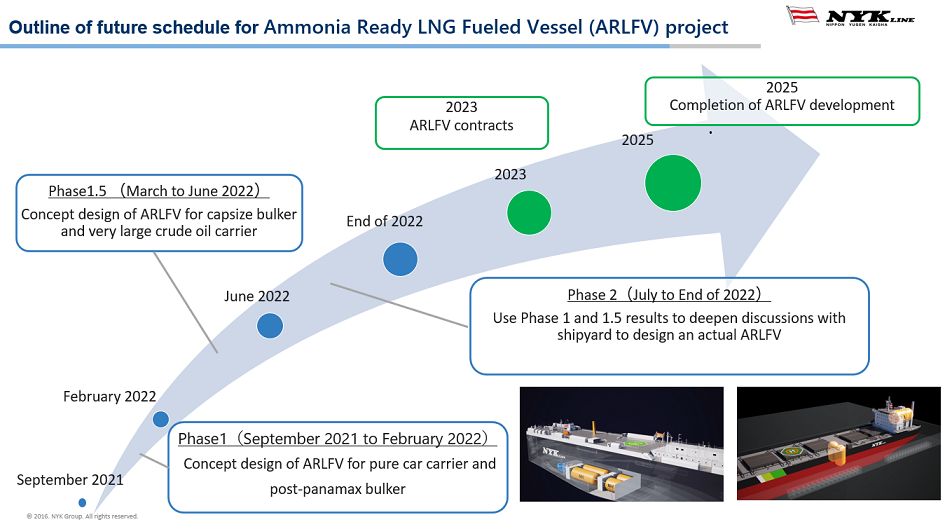

5. A concept design for up to four types of ammonia-ready, LNG-fueled vessels (ARLFV) from NYK Line.