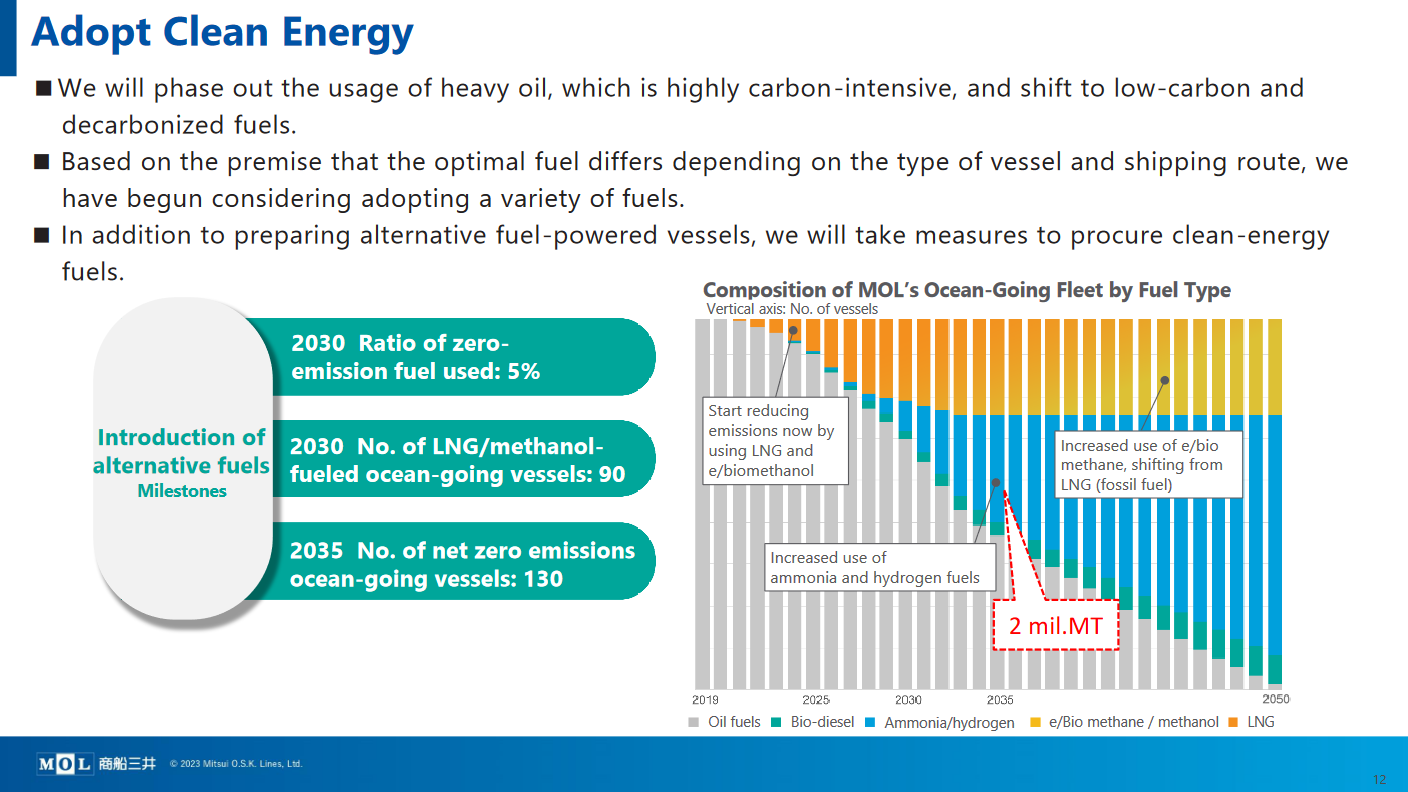

New marine engine partnerships to accelerate deployment

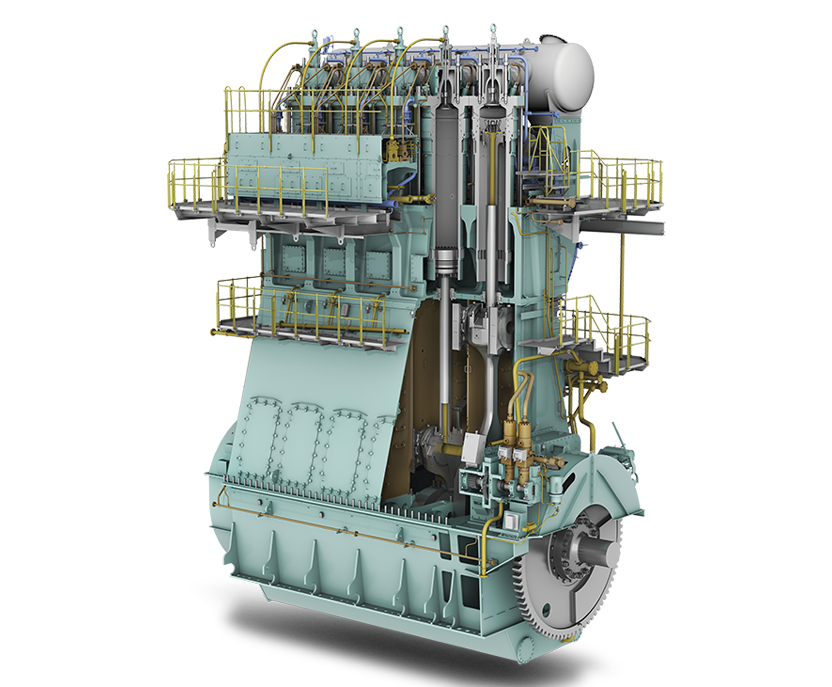

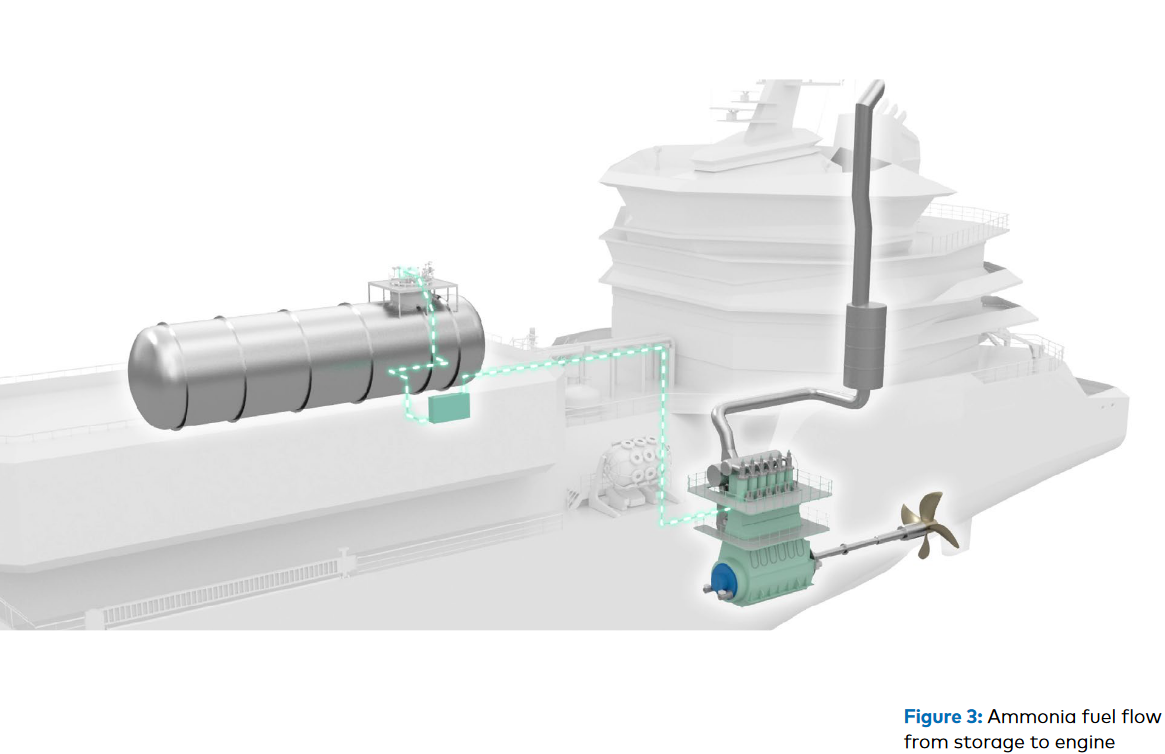

Expected to become commercially available in 2025, WinGD’s X-DF-A ammonia powered engines will be fitted on Samsung Heavy Industries’ newbuild vessels. Eastern Pacific Shipping expects its ammonia powered Newcastlemaxes and VLAC fleet to be delivered from 2026 onwards, after signing a series of agreements with MAN Energy Solutions and other key partners.