Ammonia Gas Turbine

Two Stage Ammonia Combustion in a Gas Turbine like Combustor for Simultaneous NO and Unburnt Ammonia Reductions

Development of Low-NOx Combustor of Micro Gas Turbine Firing Ammonia Gas

Ammonia-Hydrogen Power for Combustion Engines

Ammonia for Power: a literature review

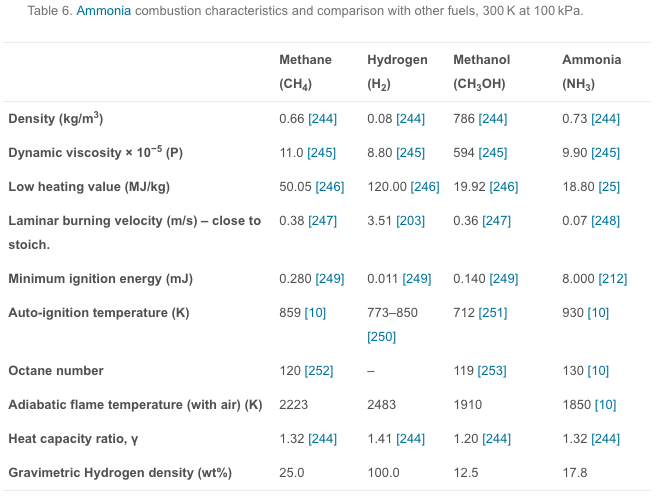

"Ammonia for Power" is an open-access literature review that includes over 300 citations for recent and ongoing research in the use of ammonia in engines, fuel cells, and turbines, as well as providing references to decades of historical case studies and publications. The review, written by a consortium of ammonia energy experts from the University of Cardiff, University of Oxford, the UK's Science and Technology Facilities Council, and Tsinghua University in China, can be found in the November 2018 edition of Progress in Energy and Combustion Science.

IHI Commits to Ammonia Energy. Big Time.

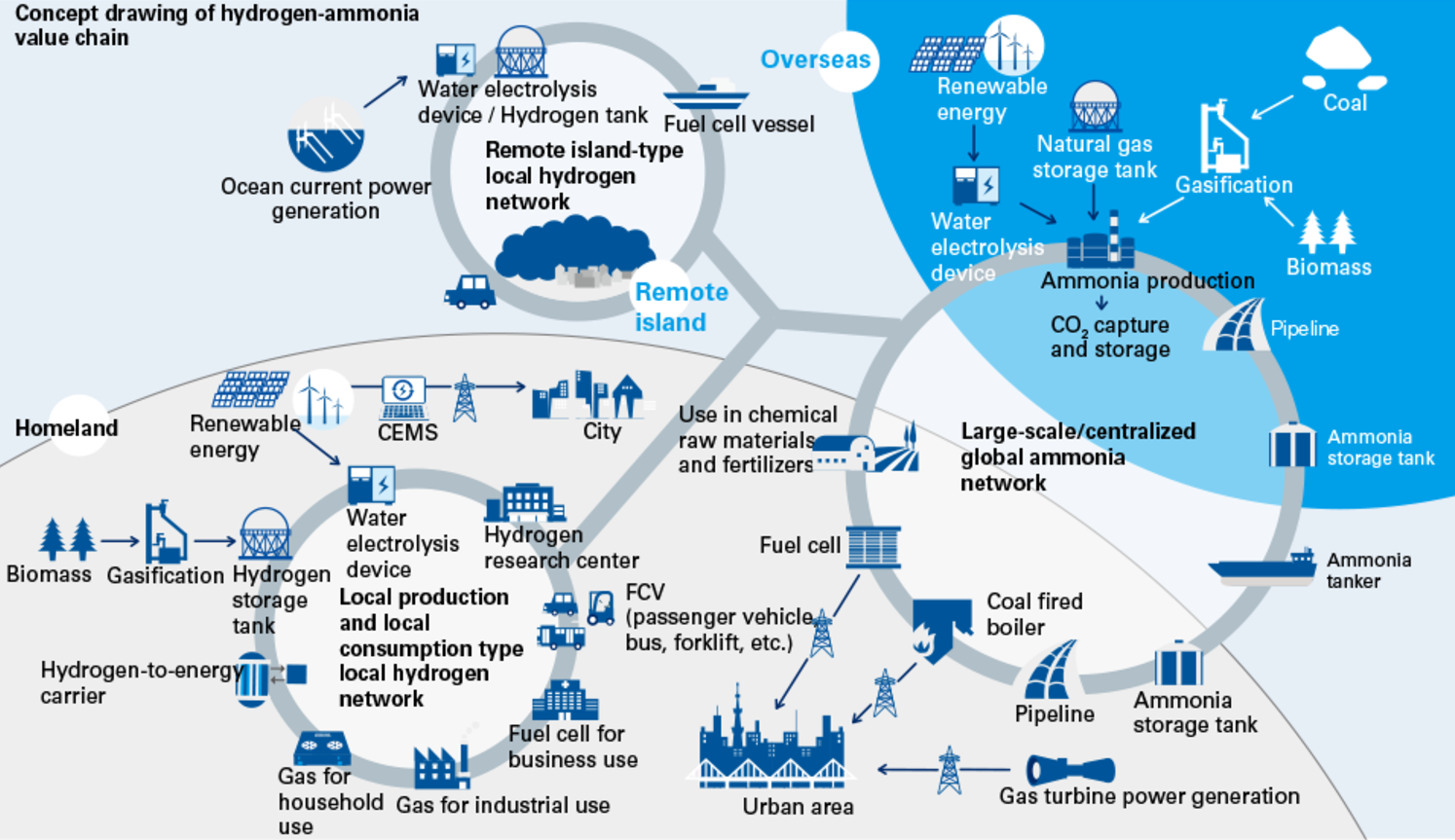

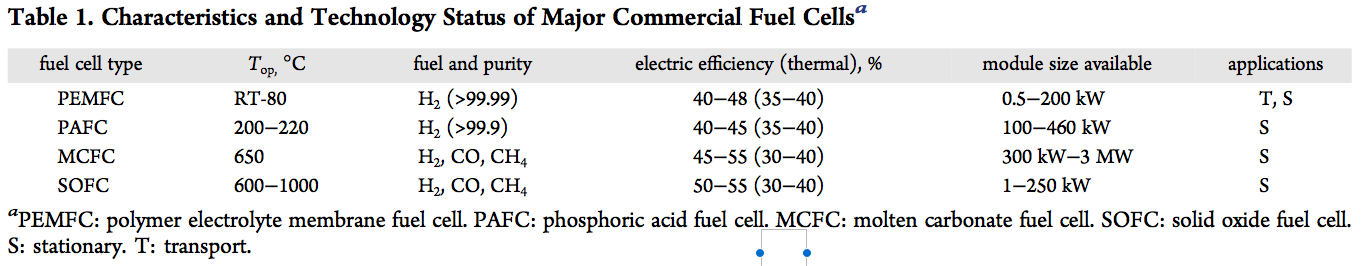

During his presentation at the November 2017 NH3 Energy + Topical Conference, Shogo Onishi of IHI Corporation described the progress made by IHI and Tohoku University in limiting NOx emissions from ammonia-fired gas turbines (AGTs). Regular attendees of the annual NH3 Fuel Conference identify IHI with its work on AGTs since the company also addressed this topic at the 2016 and 2015 events. However, a scan of published materials shows that AGTs are just one aspect of IHI’s activity in the ammonia energy arena. In fact, IHI is also looking at the near-term commercialization of technologies in ammonia-coal co-firing in steam boilers and direct ammonia fuel cells. This level and breadth of commitment to ammonia energy is unique among global capital goods producers.

Green Ammonia Consortium Comes to the Fore in Japan

On December 8, the Nikkei Sangyo Shimbun ran a story about the future of coal-fired electricity generation in Japan. The story touched on topics ranging from the plumbing in a Chugoku Electric generating station to the Trump administration’s idiosyncratic approach to environmental diplomacy. And it contained this sentence: “Ammonia can become a ‘savior’ of coal-fired power.” Clearly an explanation is in order.

Combustion Emissions from NH3 Fuel Gas Turbine Power Generation Demonstrated

Round-trip Efficiency of Ammonia as a Renewable Energy Transportation Media

A new study has made a major addition to the available literature on the economic benefits of ammonia energy. This latest study, published by researchers from CSIRO in Australia, provides the data needed to define the round-trip efficiency of using ammonia as a sustainable fuel and hydrogen carrier.

SIP "Energy Carriers" video: ammonia turbines, industrial furnaces, fuel cells

To demonstrate the progress of the SIP "Energy Carriers" program, the Japan Science and Technology Agency last week released a video, embedded below, that shows three of its ammonia fuel research and development projects in operation. R&D is often an abstract idea: this video shows what it looks like to generate power from ammonia. As it turns out, fuel cells aren't hugely photogenic. Nonetheless, if a picture is worth a thousand words, this will be a long article.