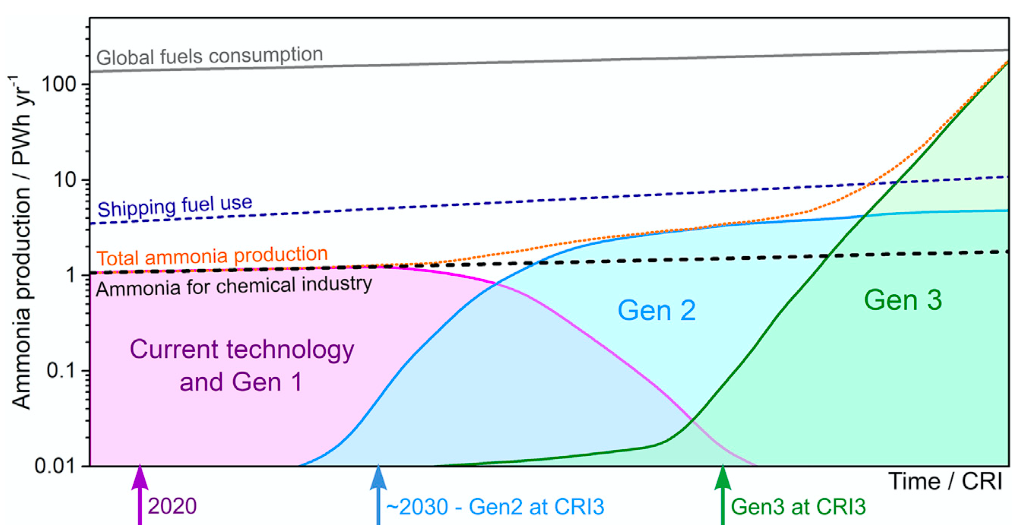

Earlier this month, Doug MacFarlane and his team of researchers at Monash University published A Roadmap to the Ammonia Economy in the journal Joule. The paper charts an evolution of ammonia synthesis “through multiple generations of technology development and scale-up.” It provides a clear assessment of “the increasingly diverse range of applications of ammonia as a fuel that is emerging,” and concludes with perspectives on the “broader scale sustainability of an ammonia economy,” with emphasis on the Nitrogen Cycle. The Roadmap is brilliant in its simple distillation of complex and competing technology developments across decades. It assesses the sustainability and scalability of three generations of ammonia synthesis technologies. Put simply, Gen1 is blue ammonia, Gen2 is green ammonia, and Gen3 is electrochemical ammonia. It also outlines the amount of research and development required before each could be broadly adopted (“commercial readiness”). The paper thus provides vital clarity on the role that each generation of technology could play in the energy transition, and the timing at which it could make its impact.

Ammonia Synthesis

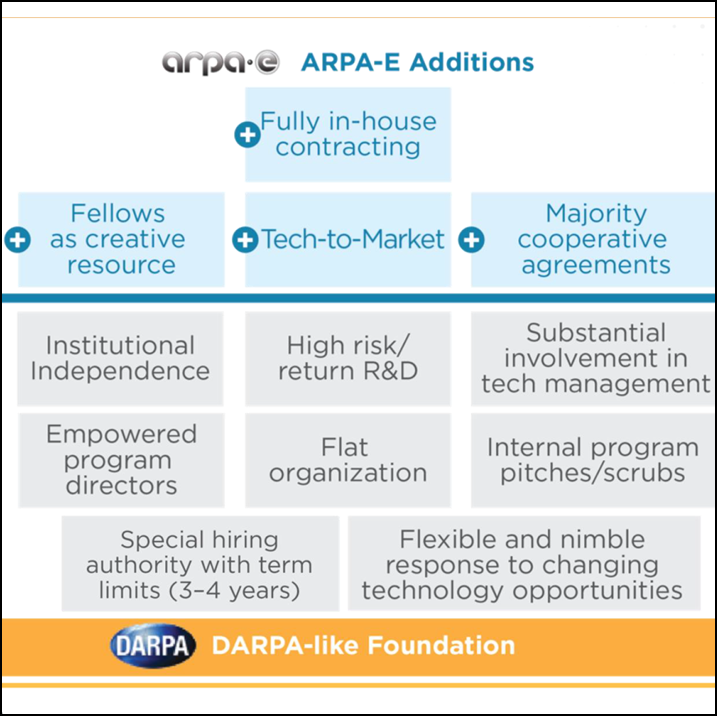

ARPA-E Issues RFI for Next-Gen Ammonia System Integration

This week the United States Department of Energy’s Advanced Research Projects Agency – Energy (ARPA-E) issued a Request for Information under the title “Next Generation Ammonia System Integration Project.” This is a strong signal that ARPA-E intends to see the ammonia energy technologies in its portfolio through to commercial fruition.

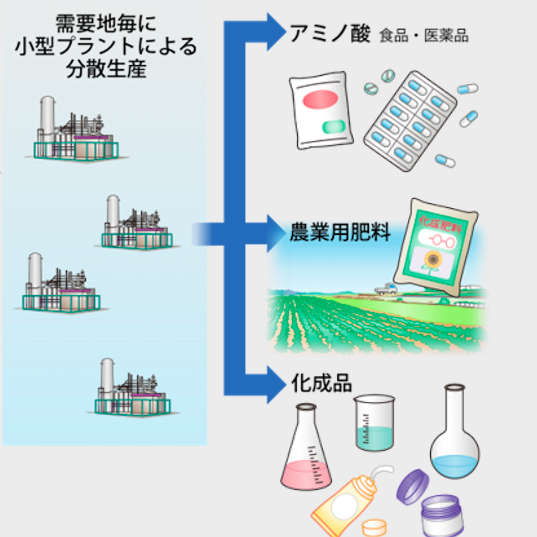

Small-Scale Ammonia Synthesis Technology on Track for 2021

On October 6, 2019, the Nihon Keizai Shimbun published an article that confirmed a goal set at the 2017 launch of Japanese chemical technology developer Tsubame BHB. The goal is to have Tsubame’s ammonia synthesis technology ready for licensing in 2021. According to Tsubame’s English-language Web site, its technology “makes it possible to produce ammonia even at small-scale plants” – good news for ammonia energy project developers interested in distributed production concepts.