Catalysts

Ammonia-fueled four-stroke engine performance & implementation, fuel supply systems

Catalyst Solutions for Clean Ammonia Energy: From Emission Control to Ammonia Cracking

Amogy, A*STAR target ammonia-to-power demo on Jurong Island

As part of the new MoU, A*STAR will join Amogy in R&D on ammonia cracking catalysts, develop digital tools and workforce training programs for scale-up, and eventually demonstrate one of Amogy’s ammonia-to-power systems on Jurong Island.

Duiker Clean Technologies: FID reached for pilot ammonia cracking facility

Duiker Clean Technologies will construct and operate an industrial-scale pilot plant for its ammonia cracking technology in the Netherlands, thanks to government and EU funding.

Industrial demonstration of ammonia cracking: exploring global progress

Here, we explore the current demonstration landscape for large-scale cracking. To produce pipeline-quality hydrogen at future energy import hubs, industrial-scale ammonia cracking is still to be derisked and demonstrated, although certain parts of the overall process have been proven at scale. What are the technology elements to be considered, and who are the first-movers deploying the technology in a variety of global locations?

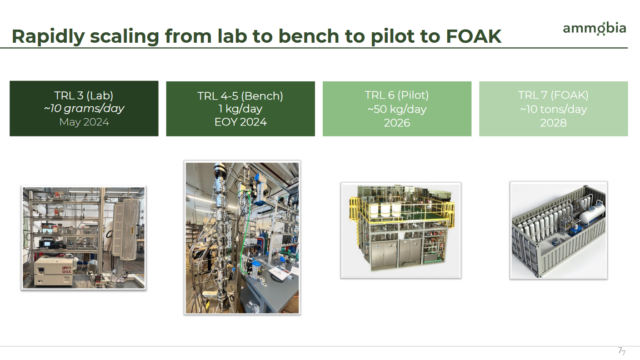

Funding for ammonia energy startups in 2024

2024 has seen successful funding rounds for a number of ammonia energy startups, ranging in focus from catalyst development to next-generation, modular synthesis technologies.