Technology status: PEM electrolysis for renewable ammonia production

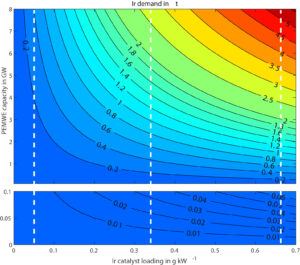

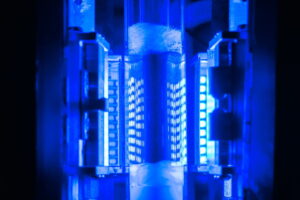

Recent PEM technology developments have centered around two issues: i) the relative scarcity of Iridium, and ii) the membrane thickness, limiting the efficiency of the PEM electrolyzer. This week we explore new approaches to both, including work by precious metal company Heraeus, and Norwegian start-up HyStar.