CCS Ammonia

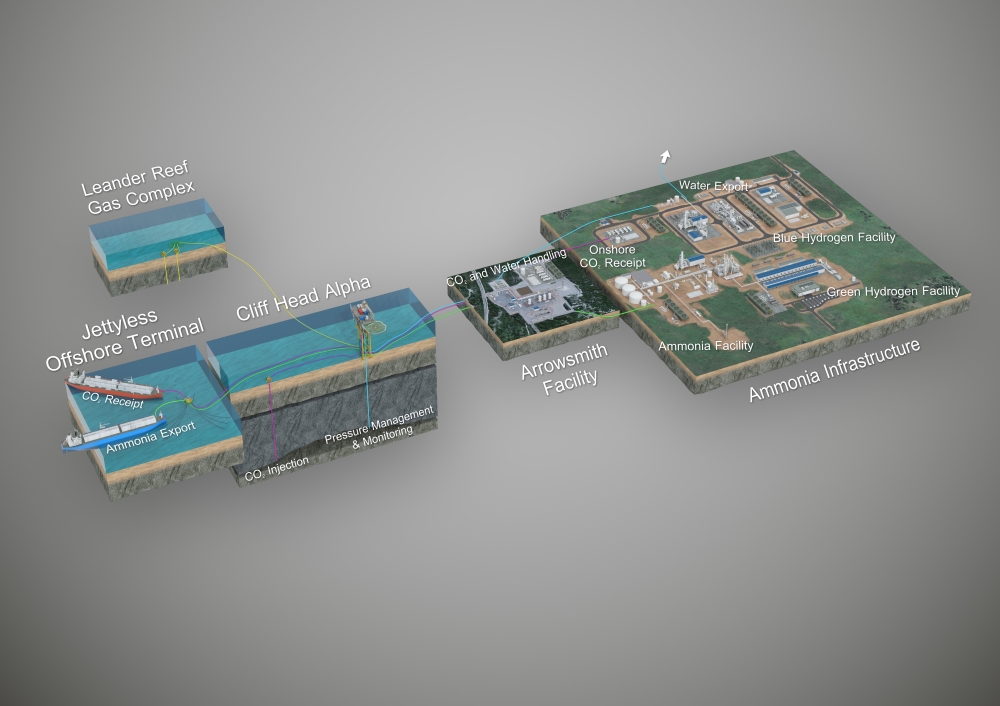

CCS-based ammonia exports from Australia & Canada to South Korea

Two mega-projects will establish CCS ammonia supply chains to South Korea for use as a power generation fuel. In Western Australia, Pilot Energy and new project partners Samsung C&T will develop the Mid West Clean Energy Project, while Hydrogen Canada Corp has announced a Korean offtaker for its production project near Fort Saskatchewan, Alberta.

Namikata Terminal to be repurposed into an ammonia-ready clean energy hub

Led by Mitsubishi, a new seven-member council will seek to transform Namikata Terminal in southern Japan into an ammonia-focused clean energy hub. The hub will handle over 1 million tonnes of ammonia annually, receiving imports from production hotbeds such as Corpus Christi & Lake Charles on the US Gulf Coast.

LSB Industries & partners: low-carbon ammonia production on the Houston Ship Channel

LSB Industries, Vopak Moda, INPEX and Air Liquide will collaborate on the pre-FEED stage for a new, mega-scale, CCS-based ammonia project to be located on the Houston Ship Channel. From 2027, the new plant will produce over 1.1 million tonnes of ammonia per year.

US hydrogen hubs revealed: coast-to-coast projects to anchor new industry

The US Department of Energy has selected seven hydrogen hub applications to proceed to a funding negotiation stage, with $7 billion to be split between them. Fertiliser, power generation, industrial decarbonisation and heavy vehicle transport are all target markets for the new hubs, with locations to range from the Gulf Coast, Appalachia, the Midwest to the Californian coast.

OCI Global: renewable ammonia in Texas

OCI will offtake electrolytic hydrogen feedstock from New Fortress Energy’s ZeroParks facility from 2025, allowing for the production of 80,000 tonnes per year of renewable ammonia at its Beaumont plant in Texas. This “over-the-fence” feedstock approach will also be employed in the development of a new multi-million tonne per year, greenfield ammonia plant in Beaumont, with Linde to own & operate an adjacent, CCS-based hydrogen production plant.

Barents Blue: new CCS operator, partnership with Fertiberia

Horisont Energi will partner with PGNiG Upstream Norway for the Barents Blue ammonia project. After the departure of original CCS partners Equinor and Vår earlier this year, Horisont also announced that Fertiberia would join as 50:50 development partner.