Nel Stakes a Claim on Another Key Frontier of Hydrogen Implementation

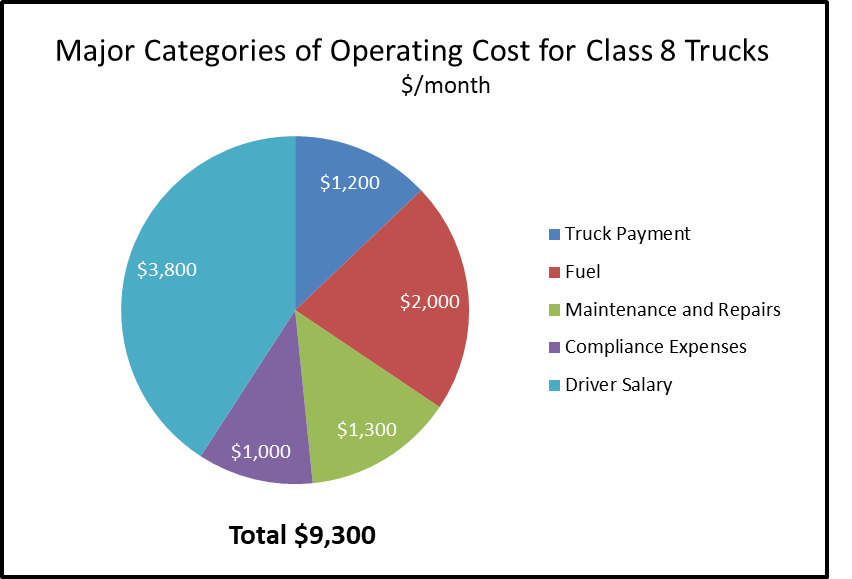

On June 28, Norwegian hydrogen company Nel ASA issued a press release announcing that the company will supply “448 electrolyzers and associated fueling equipment to Nikola Motor Company as part of Nikola’s development of a hydrogen station infrastructure in the U.S. for truck and passenger vehicles.” The Nikola-Nel arrangement is a globally significant step in the process of implementing a full-scale hydrogen energy economy. And although its approach for supplying green energy to hydrogen fueling stations does not involve ammonia, it seems likely it will ultimately help make the case for ammonia as an economically advantaged option.