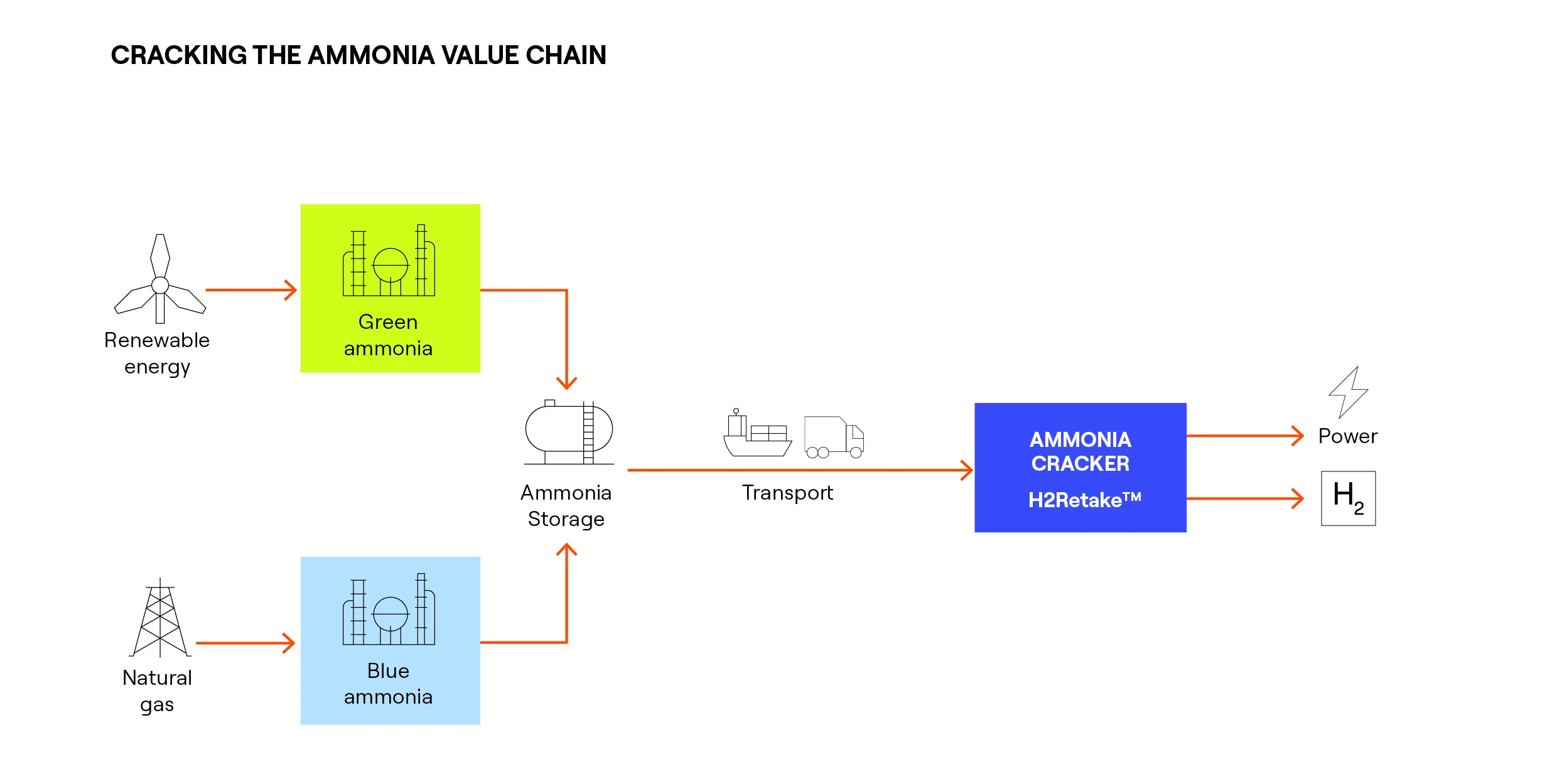

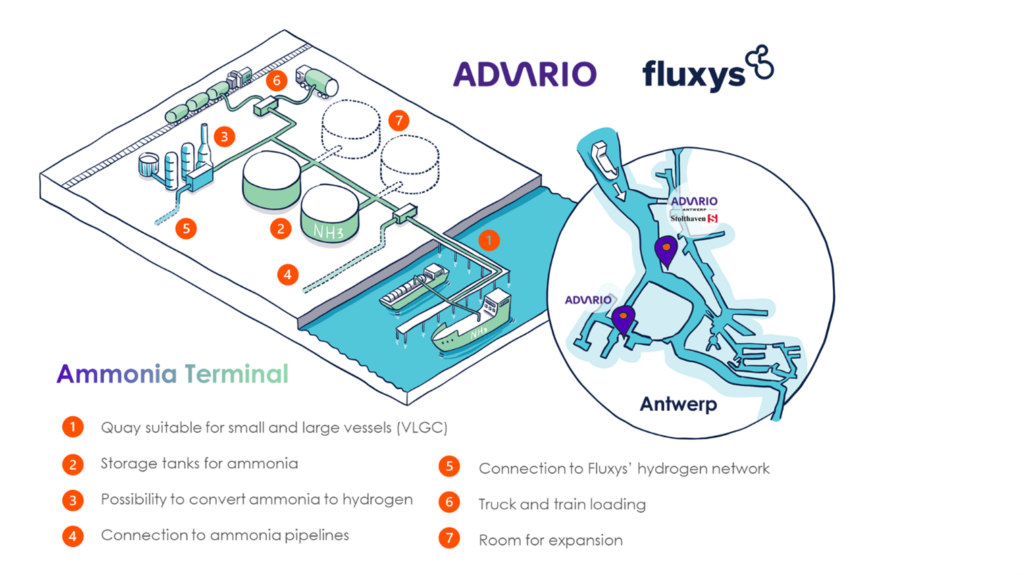

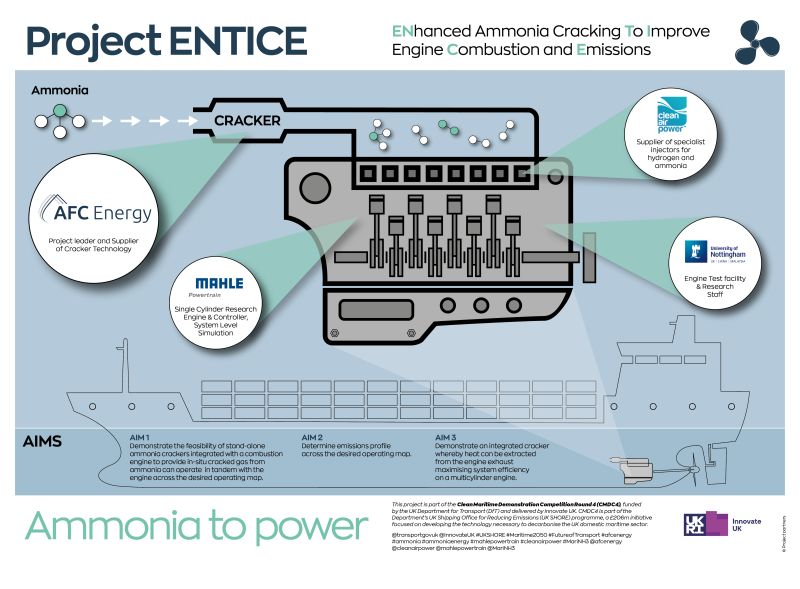

Ammonia logistics as a hydrogen energy carrier may follow different paths: large-scale crackers and distributed applications for industry or mobility. In this work, the focus is on the distributed applications for mobility, dimensioning a Hydrogen Refuelling Station Case and giving the current status of the Ammogen projects that will follow a similar schema. A real comparison between supply with current hydrogen cylinder deliveries and supply with green ammonia and crack it back to hydrogen onsite before its use. Advantages regarding logistics, technology scaling opportunities and potential for improvement are considered for this application. Finally, the main challenges that are being…