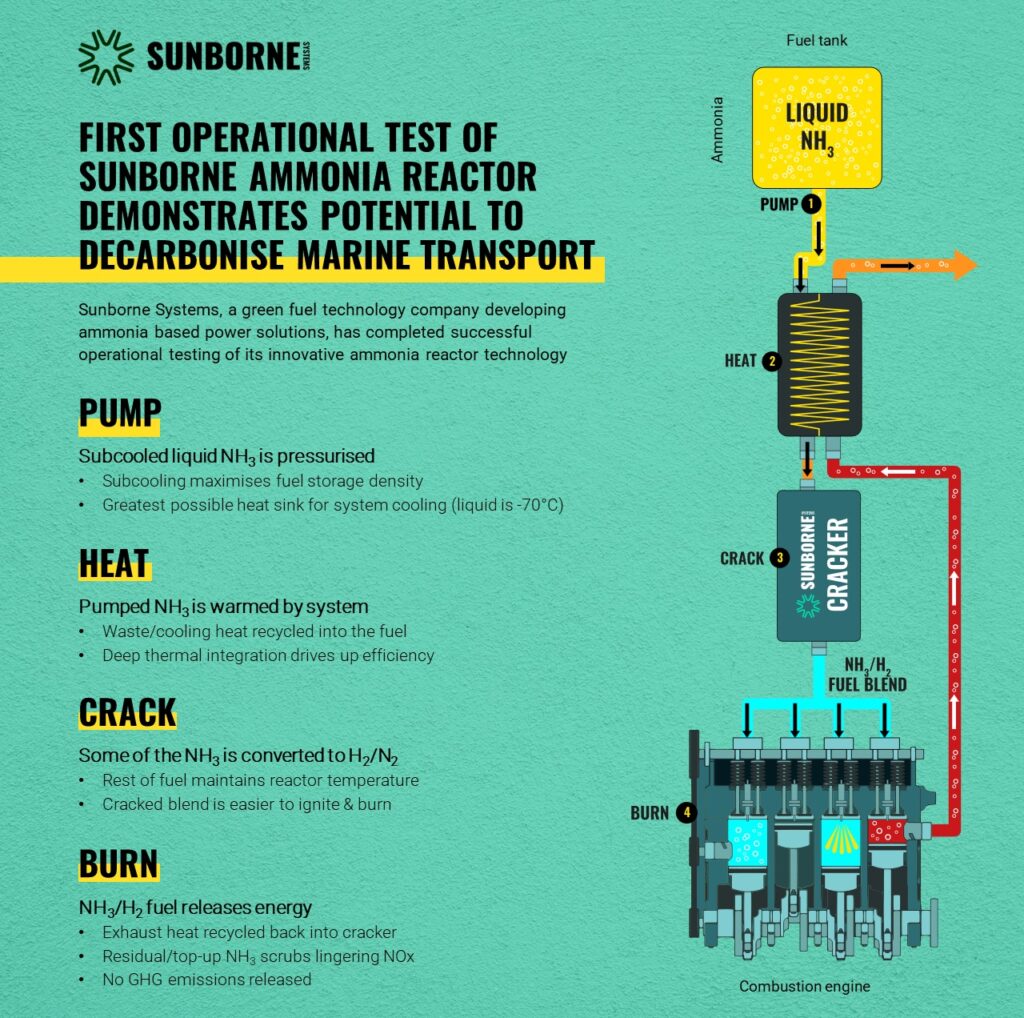

Sunborne Systems ran a successful demonstration for its ammonia cracking reactor in Oxford, producing a fuel blend capable of powering a small vehicle or small generator unit. Also in the UK, AFC Energy announced a similarly successful demonstration of its integrated cracker and purifier system, producing hydrogen fuel which meets purity & ISO standards for heavy vehicle refueling.

Cracking Ammonia

KBR to provide cracking tech for new South Korean project

KBR will deploy its new H2ACTSM ammonia cracking technology in Daesan, South Korea, delivering 200 tonnes of hydrogen per day as fuel for power generation. The new project is part of Hanwha Corporation’s decarbonisation push which includes co- and 100% firing of hydrogen fuel in gas turbines, ammonia production & export, and ammonia-powered vessels.

The NH3 Kraken: Amogy’s ammonia-powered tugboat

As part of our Maritime Ammonia Insights series, we explore progress onboard the NH3 Kraken, Amogy’s ammonia-powered tug being developed in New York state. We heard updates on vessel retrofits, design points, project partners, the ongoing relationship with the US Coast Guard, HAZOP assessments, regulatory work and the remaining challenges before the tug hits the water for operational trials. Amogy’s Abigail Jablanksky and Chief Safety Solutions’ Herbert Fowlkes joined Conor Furstenberg Stott in conversation.

Tracking the development pipeline of ammonia-ready vessels

In vessel news this week:

- Samsung Heavy Industries’ ammonia-powered, ultra-large ammonia carrier design has been granted AiP by Korean Register.

- Pherousa Green Shipping’s new fleet of six Ultramax vessels will be developed alongside partner OSM Thome.

- And Avance Gas has triggered the option of two mid-sized LPG/ammonia carriers, noting growth in global seaborne ammonia trade.

Japan consortium to explore ammonia imports to Osaka

Mitsui & Co., Mitsui Chemicals, IHI Corporation and the Kansai Electric Power Company will explore the establishment of a hydrogen & ammonia supply chain based in Osaka. Ammonia fuel will be used to decarbonise electricity generation, and cracked to provide a feedstock for other industrial processes like steel-making. In South Korea, a similar partnership is evolving between LOTTE and Air Liquide. You can learn more about the emerging nexus between ammonia cracking and steel-making at our upcoming annual conference in Atlanta, USA.