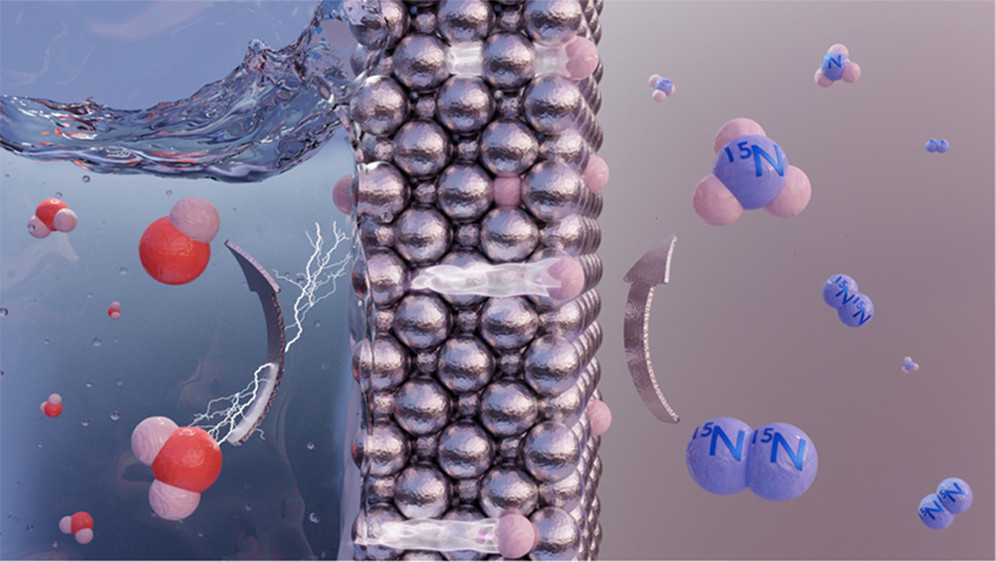

A road ahead via lithium-mediated electrochemical nitrogen reduction?

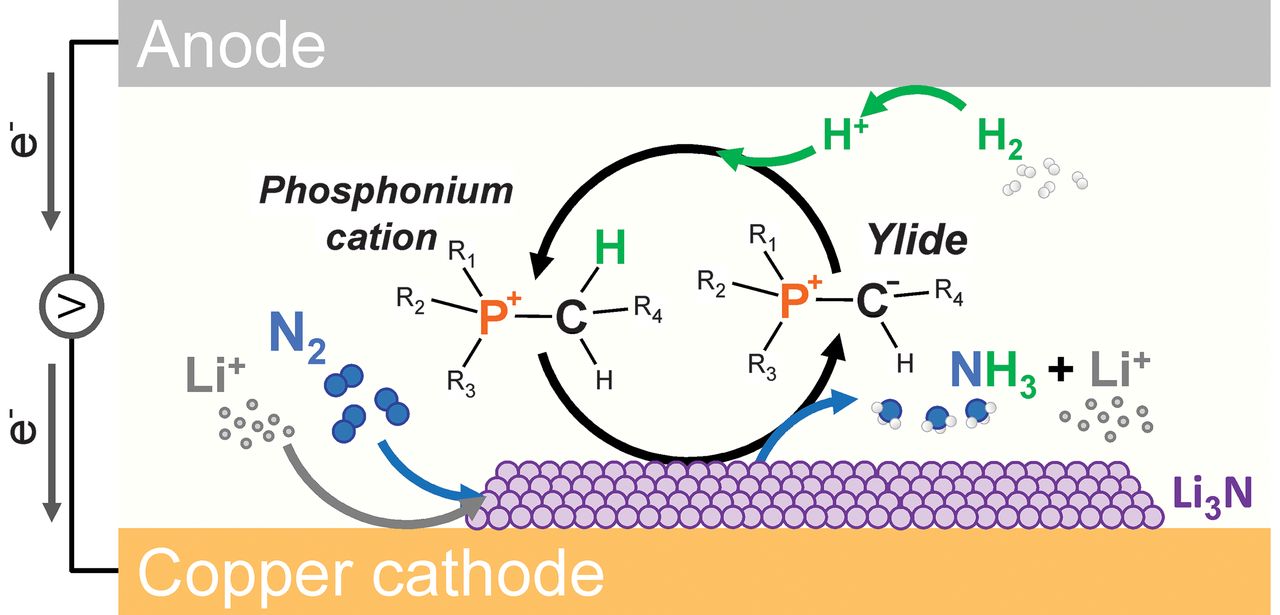

Realisation of electrochemical nitrogen reduction to ammonia has proven to be a herculean scientific challenge. Recently, a focus on Lithium-mediated synthesis has delivered promising results. Last year a team from Monash University in Australia unveiled their phosphonium “proton shuttle” method, and this year have reported nearly 100% Faradaic efficiency for the reaction (with promising reaction rates). Late last year, a team from the Technical University of Demark (DTU) reported that addition of small amounts of oxygen gas drastically increased Faradaic efficiencies and production rates. The results push electrochemical synthesis R&D ever-closer to elusive benchmarks set for commercial realisation.