Gigastack Phase 2 Receives Funding in the UK

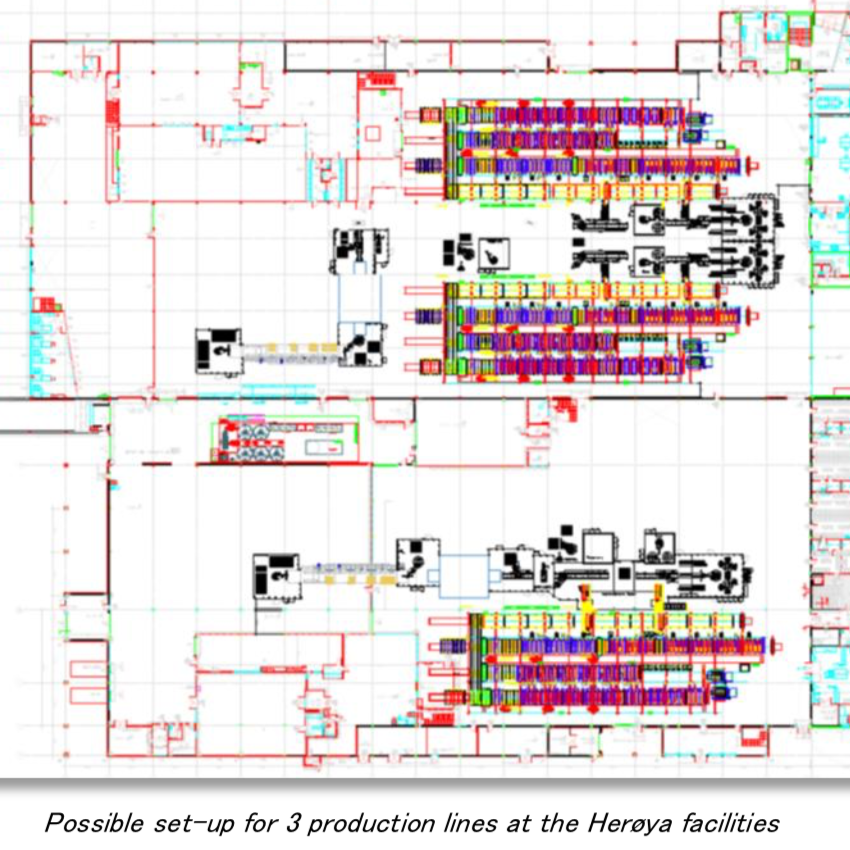

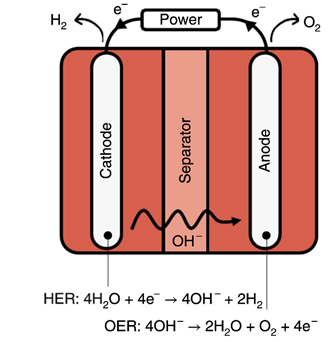

Earlier this week the United Kingdom’s Department for Business, Energy & Industrial Strategy (BEIS) announced that a group led by ITM Power has been awarded GBP 7.5 million (USD $9.7 million) for the second phase of a renewable hydrogen project dubbed “Gigastack.” According to the BEIS announcement, “Gigastack will demonstrate the delivery of bulk, low-cost and zero-carbon hydrogen through ITM Power’s gigawatt scale polymer electrolyte membrane (PEM) electrolysers . . .” with the goal of “dramatically reduc[ing] the cost of electrolytic hydrogen.” The hydrogen produced will be used for petroleum refining, although the project partners have their eyes on opportunities that go well beyond desulfurization of oil.