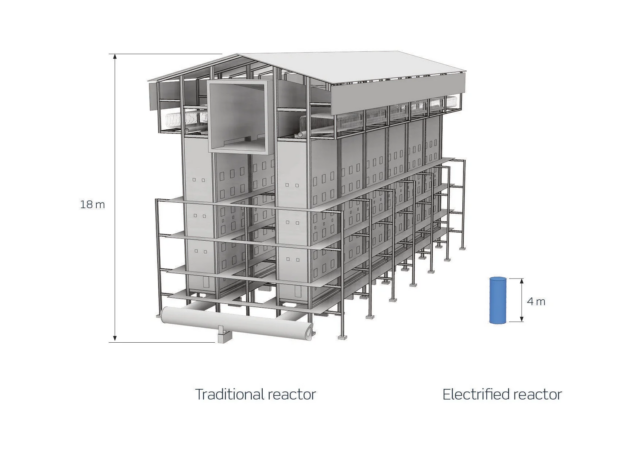

Clariant catalyst to feature in largest electric SMR project to date

Clariant will manufacture catalysts for a new electric steam methane reformer (eSMR) project, which will begin producing 150 tons per day of syngas from 2026. The 10 MW unit will be fed with renewable electricity, producing syngas for a to-be-named German customer.