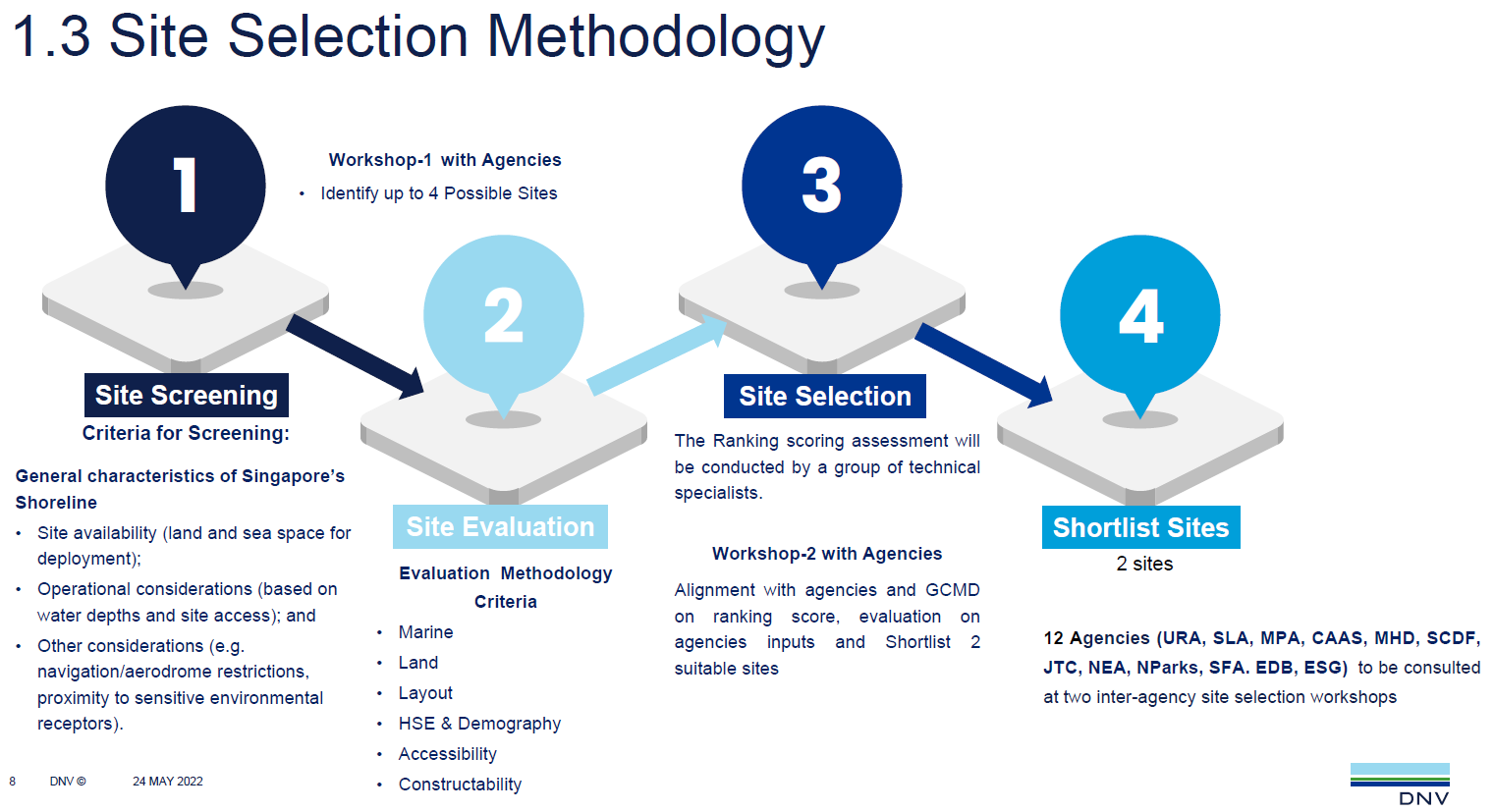

Our latest episode of Maritime Ammonia Insights revealed key details about the Ammonia Bunkering Safety Study currently being undertaken in Singapore. The study is led by the Global Center for Maritime Decarbonisation (GCMD), with DNV acting as a consulting partner. Lau Wei Jie (GCMD) took us through the high-profile lineup of study partners, and explained how the study aims to develop an extensive technical guideline for ammonia bunkering, similar to TR 56 (which covers LNG bunkering). Dr. Imran Ibrahim (DNV Maritime Advisory), then explained the technical scope of the study, how pilot project sites will be selected, and how the study partners are using previous work from Rotterdam and Oslo to hone their approach. Our audience was eager to understand how this work in Singapore might be applied elsewhere, and keenly awaits the results, which are due for public release in February 2023.