Zero-carbon shipping

NH3 Clean Energy: bunkering and CCS agreements for flagship project

NH3 Clean Energy will collaborate with Woodside to progress the Angel CCS project offshore of the Pilbara in northwestern Australia. Meanwhile, NH3 will work with Oceania Marine Energy and Pilbara Ports to establish an ammonia bunkering service at the Port of Dampier by 2030, targeting iron ore transport between Australia and Asia.

Emission performance of ammonia-fueled, four-stroke marine engines

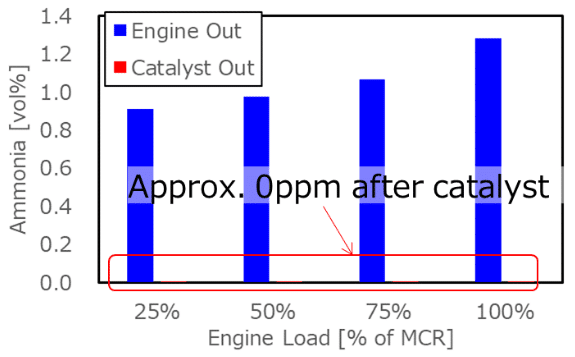

We explore recent, full-scale, four-stroke engine testing results from IHI and Wärtsilä. Testing indicates N2O emissions can be almost fully eliminated with catalytic treatment, and significantly lower NOX emissions for engines running in ammonia mode, compared to running on diesel. While ammonia slip remains a key consideration due to the design of a four-stroke engine, catalytic treatment of the exhaust can eliminate even high concentrations, and release mitigation systems have already been designed and deployed to ensure safe operations.

Ammonia marine fuel cheapest option from late 2030s, dual-fuel vessels lowest-risk

Based on their analysis, UMAS and the University College of London conclude that scalable e-fuels have the highest potential to meet shipping’s new decarbonization targets, but that the next decade is critical to ensure supply chains are ready to supply these fuels. Ammonia-LNG dual-fuel vessels represent the lowest-risk, cheapest decarbonization option to the mid 2030s.

Trafigura orders ammonia dual-fuel vessels from South Korea

Trafigura has signed a contract for four medium-sized gas carriers, featuring WinGD dual fuel ammonia engines. The vessels will be built at HD Hyundai Mipo Dockyard in Ulsan, South Korea, and the first ship will be delivered in 2028.

Class societies prepare for marine ammonia fuel: safe operations, crew training, and risk management

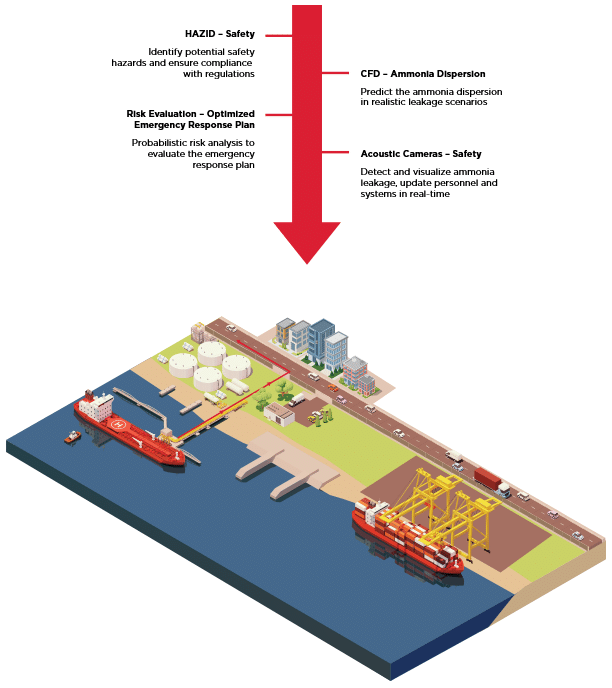

ClassNK, DNV, Lloyd’s Register and the American Bureau of Shipping have all released new resources to support the implementation of marine ammonia fuel. We explore vessel operation guidelines and best-practice recommendations, seafarer training programs, and models for ammonia leak dispersion onboard vessels.

Emission performance of ammonia-fueled, two-stroke marine engines

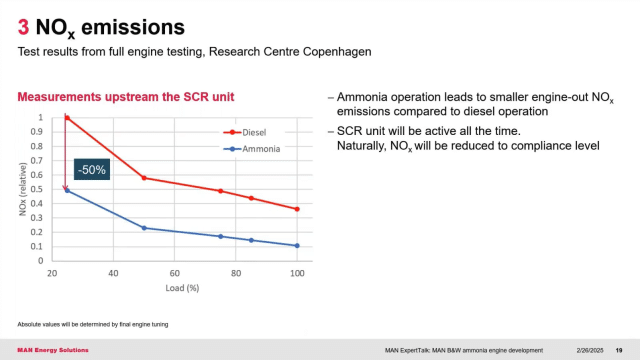

We explore recent, full-scale, dual-fuel engine testing results from leading maritime vendors such as MAN Energy Solutions and WinGD. Testing indicates negligible emissions of the potent GHG N2O (which can be fully eliminated with catalytic treatment), and significantly lower NOX emissions for engines running in ammonia mode, compared to running on fuel oil or diesel. Overall, compliance with IMO Tier II and III emission limits is well within reach for the first generation of ammonia-fueled maritime engines.

UK Coastguard, Department of Transport: preparing for ammonia-fueled vessels

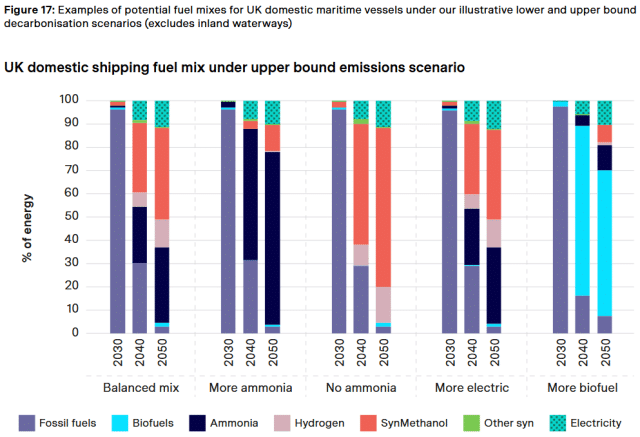

The UK’s Maritime and Coastguard Agency has set out timelines and processes for operators of ammonia-fueled vessels to engage with authorities in preparation for operations in UK waters. Ammonia fuel is included in the Department of Transport’s first-ever Maritime Decarbonisation Strategy, with as much as 70% of the forecast fuel mix being ammonia by 2050.

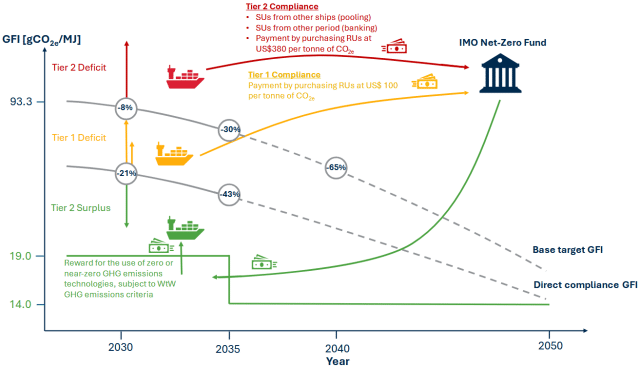

MEPC 83: global shipping gets its first-ever emissions pricing mechanism

The regulations send a clear signal to industry – business as usual operations will become significantly more expensive, and zero or near-zero (ZNZ) technologies and fuels represent one of the better opportunities to make deep emissions cuts. Following the historic vote at the IMO, we explore critical timelines for the new regulations, compliance thresholds, mechanisms for vessels to comply, and uncertainties that remain.

Fortescue & CMB.TECH: charter signed for ammonia-powered iron carrier

The Newcastlemax vessel is expected to be delivered to Fortescue by the end of 2026, and will feature WinGD’s X‑DF‑A dual-fuel engine. The vessel is one of a series under construction at Qingdao Beihai Shipbuilding in China.