University of Minnesota’s Ammonia Program

By Stephen H. Crolius on December 16, 2016

The American Institute of Chemical Engineers (AIChE) will present a Webinar on December 21 on “Distributed Ammonia Synthesis.” The presenter will be Edward L. Cussler, Distinguished Institute Professor at the Chemical Engineering and Materials Science (CEMS) Department of the University of Minnesota.

Distributed ammonia synthesis is one focus related to ammonia energy at the University of Minnesota – but just one. In fact, UMinn is the locus of a unique and globally significant collection of research efforts that promise to have significant impacts in the ammonia industry and the broader energy sector. The UMinn research program is notable both for the range of its interests and for the collegial consultation that links the individual pieces into a purposeful whole.

The story started in the early 2000s with an initiative by UMinn’s West Central Research and Outreach Center (WCROC). Led by Director of Renewable Energy Mike Reese, the Center obtained a state grant to construct a wind-to-hydrogen demonstration system.

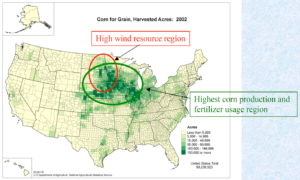

The case for the project was built on three observations: first, Minnesota produces no fossil fuels and imports more than $10 billion worth of energy each year; second, the western part of the state has abundant wind resources; and third, the southwestern part of the state lies in the corn belt that includes northern Illinois, Iowa, and eastern Nebraska.

The original vision was to covert wind to hydrogen that could be used to power the transportation sector. This hydrogen economy could be given a boost in the near-term by converting hydrogen to ammonia that could be sold into the local agricultural market.

Even as Reese was overseeing construction of the demonstration system at the WCROC, he built alliances with other UMinn stakeholders with capabilities relevant for practical realization of the green energy vision. These included faculty members from the UMinn Institute of Technology (since renamed the College of Science and Engineering); the College of Food, Agriculture, and Natural Resource Sciences; and the Institute on the Environment.

A core premise of wind-to-ammonia is that economic plant scale will be much smaller than the 1,000+ ton-per-day facilities common in today’s ammonia industry. Two different groups are now working on ammonia synthesis approaches that could help with the economics of small-scale, “distributed” plants.

One group, led by Cussler and Professor Alon McCormick, also of the CEMS Department, is working on a method that employs “reactive separation” using calcium carbonate as an absorbent to capture ammonia as it is synthesized. According to a paper published in Industrial Engineering & Chemistry Research, this method enabled benchmark ammonia synthesis parameters to be achieved even with a significant reduction in reaction vessel pressure.

Another group, led by Rongsheng Ruan of the Department of Bioproducts and Biosystems Engineering, is investigating a method of ammonia synthesis that is compatible with both lower temperatures and pressures. This method is based on technology Ruan developed while studying production of fuels from biomass feedstocks. The technology, as described in a pending patent application, involves non-thermal plasma (NTP). According to a presentation delivered at the 2015 NH3 Fuel Conference, NTP is a type of plasma that consists of “energized ions and highly reactive radicals made in non-pressurized gas with electrical discharge.” The patent application states that “the NTP effectively provides energy to overcome certain reaction barriers. It is believed that a non-thermal plasma works in synergy with certain catalysts directly dissociating gaseous molecules reactant to form highly reactive free radicals or ions while also possibly reducing the activation energy required by the catalysts to function efficiently.”

UMinn will be able to contribute on the fuel-use side as well, thanks to a $250,000 grant that was recently awarded to the Department of Mechanical Engineering and the WCROC (and reported in Ammonia Energy in September). The grant will fund development and demonstration of a dual-fuel engine that can power a farm tractor. Once commissioned, the engine will run on a mixture that is up to 50% ammonia by energy content. The use of compression ignition for a fuel mixture of this type puts UMinn into the same group of ammonia engine developers as Sturman Industries and Iowa State University, as detailed in an Ammonia Energy article on the range of engine technologies under development. At the heart of the system will be a thermal reformer that is integrated with the exhaust manifold and that will use the heat from the exhaust gases to produce partial decomposition of the ammonia into nitrogen and hydrogen.

The aspiration of the UMinn ammonia program extends beyond technology development. With participation from contributors such as Prodromos Daoutidis from the CEMS Department and Stephen Kelley from the Humphrey School of Public Affairs, the group is working on big-picture questions. At one end of the spectrum is the technical design of a “distributed” production system consisting of many small plants that are able to draw on local wind and biomass resources and serve regional markets for fertilizer and transportation fuels. At the other end is formulation of public policies that motivated governmental agencies could employ to encourage development of such a system.

Today, the UMinn ammonia activities sum to an integrated, multidimensional program that is working to enable real-world adoption of an alternative system of fertilizer and energy supply. According to Reese, such scope and magnitude is a long way from where he and his WCROC colleagues started in the early 2000s. “We got some money to build a wind turbine,” he said, “which made us look into the challenges for wind energy in rural areas: the expense of transmission, utility disinterest.” The idea of wind-to-hydrogen was raised, which led to investigation of large-scale electrolysis and contact with Norsk Hydro. It was the example of Norsk Hydro and its role as a pioneer in ammonia production that brought ammonia into the thought process. Ammonia was deemed a good fit for the program given the dominance of agriculture in the regional economy.

The UMinn wind-to-ammonia team has been self-organizing from the start, without top-down leadership or formal structure. Daoutidis says that a group – typically consisting of 10-12 faculty members, post-doctoral fellows, and graduate students – meets regularly to discuss matters of common interest, such as potential sources of project funding.

Reese says that funding for the effort has virtually all come from the State of Minnesota. The Legislative-Citizens Commission on Minnesota Resources, which recommends grants to be made out of the Environment and Natural Resources Trust Fund (ENRTF), has been consistently supportive – no doubt because of the group’s focus on building sustainability into the state’s rural farm economy. This aligns with the ENRTF’s goal of providing “a long-term, consistent, and stable source of funding for activities that protect, conserve, preserve, and enhance Minnesota’s air, water, land, fish, wildlife, and other natural resources.”

Registration for Cussler’s Webinar on December 21, 2016, is $69 for AIChE members and $99 for non-members.