Ammonia for energy storage: economic and technical analysis

By Trevor Brown on March 02, 2017

Developers around the world are looking at using ammonia as a form of energy storage, essentially turning an ammonia storage tank into a very large chemical battery.

In the UK, Siemens is building an “all electric ammonia synthesis and energy storage system.” In the Netherlands, Nuon is studying the feasibility of using Power-to-Ammonia “to convert high amounts of excess renewable power into ammonia, store it and burn it when renewable power supply is insufficient.”

While results from Siemens could be available in 2018, it might be 2021 before we see results from Nuon, whose “demonstration facility is planned to be completed in five years.” But, while we wait for these real-world industrial data, the academic literature has just been updated with a significant new study on the design and performance of a grid-scale ammonia energy storage system.

This new study, published in the January 2017 AIChE Journal by researchers from RWTH Aachen University and JARA-ENERGY, examines ammonia energy storage “for integrating intermittent renewables on the utility scale.”

The German paper represents an important advance on previous studies because its analysis is based on advanced energy technologies with a focus on process integration. As such, it demonstrates what ammonia can realistically achieve in the near future, not just what it was constrained to do in the past. It complements another recent study by researchers from Israel, which I discuss below, and completely updates the results published by Oxford University in 2015, which ignored the synergies of process integration.

Market size

The energy storage market is immature, and its potential size and value is swiftly evolving. The paper cites an estimated requirement of up to 28 GW / 40 TWh of “compensating capacity” in Germany, “and five times more in the United States for successful integration of fluctuating renewables.”

To put this into context, based on an energy content of about 3 MWh per metric ton of ammonia, meeting this demand with ammonia would require additional ammonia production capacity of around 13 million tons per year in Germany, or 65 million tons per year in the US, roughly four times the existing installed ammonia capacity in each country. The unanswered question is what share of the energy storage market could be captured by ammonia-based systems but, whatever fraction it will be, this presents a significant business opportunity for ammonia synthesis technology providers.

In other words, the energy storage market dwarves the fertilizer market.

Viable technology

For this to be viable, an ammonia-based energy storage system must display “High round-trip efficiency, low cost and considerable flexibility.” Maximizing efficiency – or minimizing the losses from converting power to ammonia and then back to power – is the major advancement revealed by the German paper.

This is achieved through process integration: designing a system specifically for energy storage, instead of piecing together existing technologies without synergy.

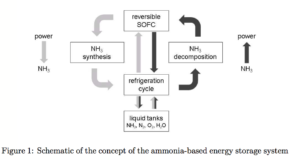

For example, a reversible solid oxide fuel cell performs two functions: it generates hydrogen from electricity and also generates electricity from hydrogen. To balance the load from intermittent renewables, these two functions are required at different times, so achieving both with one piece of technology reduces the system’s capital cost. Extensive deployment of heat exchangers throughout the system, especially between the fuel cell and the Haber-Bosch reactor, reduces the overall power requirements. And the pure oxygen stream produced by water-splitting is reused to power the fuel cell.

An ammonia-based energy storage system is proposed. It utilizes a pressurized reversible solid-oxide fuel cell for power conversion, coupled with external ammonia synthesis and decomposition processes and a steam power cycle. A coupled refrigeration cycle is utilized to recycle nitrogen completely. Pure oxygen, produced as a side-product in electrochemical water splitting, is used to drive the fuel cell …

The system can achieve a round-trip efficiency as high as 72%. The lowest levelized cost of delivered energy is obtained at 0.24 $/kWh, which is comparable to that of pumped hydro and compressed air energy storage systems.

Marquardt et al: Conceptual Design of Ammonia-Based Energy Storage System: System Design and Time-Invariant Performance, AIChE Journal 01/28/2017

I note that this levelized cost of delivered energy, at $0.24 per KWh, is better than the target set by the US Department of Energy’s ARPA-E in its “REFUEL” program, which specified a competitive “source-to-use energy” cost of $0.30 per KWh in its funding announcement for ammonia as a carbon neutral liquid fuel.

This performance was measured against a benchmark system that consisted of separate units, including a PEM-electrolyzer, Haber-Bosch synthesis unit, and a gas turbine, which displayed “a round-trip efficiency of as low as 34.2%.” For context, this benchmark is consistent with the out-dated Oxford paper, which had concluded:

As a solution for grid-level storage, ammonia seems a poor choice primarily because of its relatively low round-trip efficiency (23-41%) compared to other emerging technologies such as liquid air (50-70% round-trip efficiency) and pumped heat energy storage (72-80%).

Bañares-Alcántara et al: Analysis of Islanded Ammonia-based Energy Storage Systems, University of Oxford, 09/2015

Obviously, increasing round-trip efficiency to 72% presents a major advancement, and should encourage broader consideration of ammonia-based energy storage systems. (The Oxford paper, which is 157 pages long, nonetheless provides a valuable analysis.)

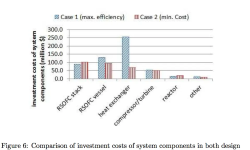

However, the German paper also specifies a second system: the first, with energy efficiency of 72%, was optimized without regard for cost; the second was optimized for cost, and yet it still displayed a round-trip efficiency of 64%, more than double the energy efficiency cited in the Oxford paper.

The authors illustrated these trade-offs between cost and energy efficiency in a chart that shows how the second system reduces capital costs, including an almost $200 million saving in heat exchangers.

The cost-optimized system was “designed for a net discharge power of 100 MW, which meets the minimum requirement of centralized energy storage for the integration of wind energy.” It assumes that the wind farm has a capacity factor of 42% (meaning the wind isn’t blowing 58% of the time), and that the ammonia system runs “a daily storage cycle with equal charging and discharging times of 10 hours.”

Two thirds of the system cost is spent on the reversible fuel cell; the process integration is achieved with “little additional investment, while the system efficiency doubles.” In addition, because “the investment cost of the storage tanks is negligible … the economics of the ammonia-based energy storage system is hardly affected by enlarging the storage tanks for longer storage cycles,” meaning that larger systems would demonstrate significant economies of scale. “The investment cost share of the storage tanks increases only by 3% from a daily to a weekly storage cycle, which corresponds to an increase in the levelized cost of merely 0.01 $/kWh.”

The ammonia-based energy storage system demonstrates a new opportunity for integrating energy storage within wind or solar farms. As the paper states, “the geographical site of a wind park does often not offer the favorable conditions for a pumped hydro or compressed air energy storage system,” because these require major physical attributes like a nearby reservoir or underground cavern.

For large-scale (MW / GWh) and long-term (hours-days) storage, this system beats batteries because of its low cost: for batteries, the “sizing of the energy capacity and the power capacity cannot be separated. Therefore, the investment cost may increase significantly, if only an expansion of the energy capacity is expected.”

The ammonia-based energy storage system presents an economic performance which is comparable to the pumped hydro and the compressed air energy storage systems. The major advantage of the ammonia-based system is the much broader applicability, because it is not constrained by geological conditions. Compared with battery technologies, the lower levelized cost of the ammonia-based storage system attributes to its capability of storing energy in large quantities over a long period of time at low cost.

Marquardt et al: Conceptual Design of Ammonia-Based Energy Storage System: System Design and Time-Invariant Performance, AIChE Journal 01/28/2017

Power-to-Fuel-to-Power

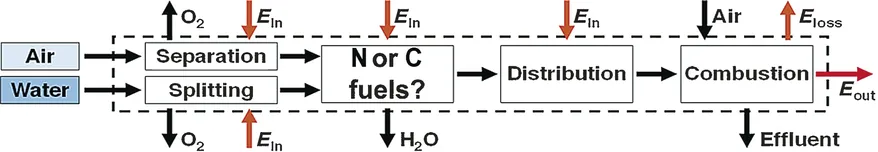

In Israel, researchers recently published a complementary study that compared carbon-based and nitrogen-based synthetic fuels. Their analysis is relevant here because it similarly examines the round-trip efficiency of the power-to-fuel-to-power cycle: their use of the word “fuel” simply refers to any medium for energy storage – including non-traditional “fuels” like UAN.

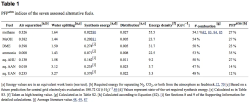

This Israeli study provides a comparison between ammonia and other, more frequently discussed carbon-based synthetic fuels, including methanol and DME, and still concludes that ammonia has the highest round-trip efficiency, according to their Power-to-Fuel-to-Power (PFP) analysis.

For synthetic fuels using electrolytic hydrogen, ammonia presents a significant advantage over carbon-based fuels by merit of its chemical structure and stochiometry. “One mole of CO2 yields only one mole of methanol using only two‐thirds of the available hydrogen. On the other hand, two moles of ammonia are produced per mole of N2, without wasting any of the hydrogen feedstock.” Water-splitting to produce hydrogen is generally the most energy-intensive part of any synthetic fuel production process, so the hydrogen wastage represented by methanol production presents a significant energy burden.

Ammonia has the lowest required energy for feedstock separation, even when compared to carbon‐based fuels in the case of flue‐gas‐derived CO2.

We showed that a nitrogen economy, where renewable hydrogen is chemically stored on abundant nitrogen in the form of a nontoxic and safe nitrogen-based alternative fuel, is energetically feasible, and that novel nitrogen-based fuels are comparable on an energy-return basis to existing carbon-based fuels.

Grader et al: Nitrogen‐Based Fuels: A Power‐to‐Fuel‐to‐Power Analysis, Angewandte Chemie, 07/25/2016

These studies make a compelling argument for the consideration of ammonia-based energy storage systems but, while we wait on data from industrial demonstrations, the German paper outlined a series of questions yet to be answered.

First, the reversible fuel cell must become proven: “The development of the RSOFC is still in an early stage. Fundamental issues, such as cell fabrication methods and reversible operation, still require further research.”

Second, improvements to the Haber-Bosch process would not only increase efficiency but also social acceptance, because the “high pressure (over 200 bar) … raises concerns about system complexity and safety. A pressure reduction helps increase the societal acceptance of the proposed concept.” I’ve written about the development of such low-pressure adaptations to the Haber-Bosch process, including projects funded under the US Department of Energy’s ARPA-E “REFUEL” program.

Third, the analysis of an ammonia energy storage system operating on a “time-invariate” (constant) basis creates an inconsistency in their assumptions, because such a system is defined as operating on 10-hour daily on/off cycles. However, they promise to address this in the next stage of their research:

The agile operability of the start-up/shut-down processes, for example, determines the frequency of the cyclic operation and thus the applicability of the energy storage system … Regarding the design methodology, given a variable load trajectory, such as a power supply curve from a large-scale wind park, sizing an energy storage system requires an evaluation of the time-dependent deployment of the system … The system design and operation of the ammonia-based energy storage system under time-variant operation will be investigated in a future publication.

Marquardt et al: Conceptual Design of Ammonia-Based Energy Storage System: System Design and Time-Invariant Performance, AIChE Journal 01/28/2017

You can also read the full article at ammoniaindustry.com.