A Fuel Standard for Ammonia: panel wrap-up from the Ammonia Energy Conference 2020

By Julian Atchison on December 15, 2020

What are the key considerations for a future Ammonia Fuel Standard? On November 17, 2020, the Ammonia Energy Association (AEA) hosted a panel discussion moderated by Ron Stanis from GTI (Gas Technology Institute), as well as panel members David Richardson from Airgas, Rob Steele from EPRI (Electric Power Research Institute), Eric Smith from IIAR (International Institute of Ammonia Refrigeration), and Dorthe Jacobsen from MAN Energy Solutions at the recent Ammonia Energy Conference. The AEA Fuel Standard Committee has been developing a draft product specification that will facilitate the acceptance of ammonia as a fuel. The overall message from panelists came through loud and clear: the draft standard is ready for stakeholder comments, and the Fuel Standard Committee welcomes your input.

Ammonia is set to play a role in decarbonisation efforts across a number of industries globally. Ammonia has the advantage of being a “new old product:” more than a hundred years of production means the technologies and standards for ammonia storage, transport, safe handling, and industrial use are mature and well-defined. But, as ammonia moves from being fertiliser to fuel, there’s one key ingredient missing: a recognised fuel standard. Moderator Ron Stanis also made the point that new players in the ammonia space (especially power utilities) are uncertain of the regulatory and permitting landscape for using ammonia as a fuel, and desperately need clarity. It’s an exciting time, and the AEA’s mixed community of career experts and ammonia rookies means we have a chance to develop a fuel standard that works for everyone: energy generators, ammonia producers, distributors, storage agents and industry regulators. So, what’s the current status of the new fuel standard, and what extra information do we need from stakeholders?

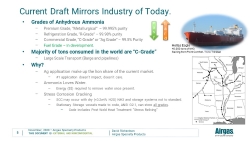

David Richardson (chair of the AEA’s Fuel Standard Committee) presented the Committee’s draft standard. There are not many surprises, as the draft standard mirrors the product specification that we see with current grades of ammonia available on the market:

- Premium or Metallurgical (Met-grade) ammonia at 99.995% purity,

- Refrigeration (R-grade) ammonia at 99.98% purity,

- Commercial or Agricultural (C-grade) ammonia at 99.5% purity, and

- A future Fuel grade ammonia to sit at or below C-grade in terms of purity.

Although most ammonia is produced at fairly high purity, it absorbs water easily and this impurity is expensive and energy-intensive to remove. It’s also well-established that a small amount of water content in ammonia (0.5% and above) significantly improves the safety of storing the product due to reduction in corrosion stress cracking – this then improves ease of distribution and safe handling. Taken together, these factors have helped shape the current market for ammonia. The biggest end user of ammonia is agriculture (consumes about 80% of global production), an industry that is sensitive to changing costs and that doesn’t require a high purity product – C-grade ammonia is therefore the cheapest, most readily available form of ammonia around the world.

So is C-grade ammonia sufficient for use as fuel? Can potential ammonia fuel customers take advantage of a readily-available, cheap product? The answer is a resounding yes. Later on in the panel session Dorthe Jacobsen outlined MAN Energy Solution’s preliminary marine fuel standard for ammonia that is based on C-grade product. Speaking for power generating customers, Rob Steele even welcomed the supply of ammonia with 2% water content – they’ll be happy to burn it as fuel! There is also demonstrated use of C-grade ammonia in fuel cells and cracking applications.

But there’s still much more work to do. We need a fuel standard that reflects a wide range of end uses and anticipates the direction the industry wants to go in. Will storage be in a vapor or liquid form? Will storage be refrigerated or pressurised? What level of impurities are end users willing to deal with? Even details like how we measure those impurities and whether we need new units of energy measurement for ammonia fuel (like BTU) are important. We need to know all these basic details from a variety of end users to get this standard right, and David and the Committee welcome your feedback.

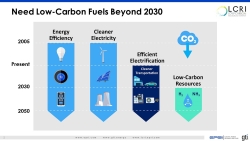

The panel then moved onto three different stakeholders for a perspective on a potential fuel standard. Rob Steele’s organisation EPRI is a newcomer to the ammonia space but represents over 90% of the electric power utility business in the USA, including a well-established gas turbine industry that has spent decades fine-tuning its machinery to produce the lowest possible NOx emissions. Any future fuel standard for ammonia needs to address the biggest concern on the minds of power generators: emissions. There’s currently more focus on hydrogen as a low-carbon fuel, but ammonia is at the top of the list for low-carbon fuel solutions in the crucial stretch between 2030 and 2050 when deep, bold decarbonisation steps will need to be taken. The power generation industry is particularly interested in ammonia-hydrogen blended fuels (90:10, 80:20 and 70:30), and the sooner we can develop world-class fuel standards and proceed with testing the better.

The International Institute of Ammonia Refrigeration (IIAR) has been advocating for and developing the highest quality standards for ammonia refrigeration for half a century, and Eric Smith is a firm believer in the wider industry controlling its own destiny on the issue of a fuel standard. The IIAR’s set of nine ammonia refrigeration standards is well-regarded by both the US EPA and OSHA, and demonstrates how industry and regulators can work together for a better outcome. IIAR has recently changed its standard to lower purity requirements for refrigeration clients, who have discovered added benefit from the improved safety, handling and storage associated with lower purity ammonia.

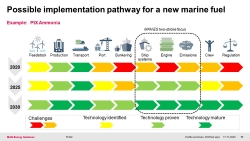

Dorthe Jacobsen closed the panel from the perspective of a marine engine designer. The last decade has seen rapid development in dual-fuel marine engines capable of burning a wide range of fuels, even though IMO and ISO have lagged behind with developing the applicable fuel standards. Ammonia is clearly a potential fuel for the marine industry long-term, though hard work is certainly required – the technical challenges for burning ammonia in marine engines need to be resolved in the next year or so for demonstration vessels to be ready by 2023-4. MAN ES has based its preliminary ammonia marine fuel design on the cheapest, most widely-available ammonia source (C-grade) and is eager to get moving – everyone’s efforts are needed to cut the shipping industry’s GHG emissions at least 50% by 2050.

If you wish to view the archived video of the fuel standard panel discussion, please register for the conference to access all session recordings. You can also browse and download all of the Ammonia Energy Conference 2020 presentations.