Ammonia-powered cruising on the Baltic Sea

By Sofia Furstenberg Stott on May 10, 2023

CAMPFIRE

Based in north-east Germany, the CAMPFIRE consortium is an alliance of impressive size & industrial clout. It gathers 76 different partners (51 local industry partners, 20 research institutes and 5 international partners), to “develop and implement green ammonia technologies to enable new economic pathways”. Their key ambitions are to decentralize storage of renewable energy, build on the current “drive in shipping to decarbonise”, find technical and safety solutions for ammonia infrastructure and logistics, and to develop legal frameworks to enable this development. Sponsored by the German Federal Ministry of Education and Research (> € 55 million), it is part of an innovation program called Wandel dursch Innovation in der Region – “Change through innovation in the region”.

GreenBalticCruising, powered by ammonia

One of the 23 CAMPFIRE projects explores an ammonia opportunity in the Baltic Sea. The GreenBalticCruising project addresses techno-economic and safety solutions for a cruise ship route across the Baltic Sea, powered by ammonia fuel. Carnival Maritime GmbH, together with Port of Rostock, Yara, DNV, IKEM, ZBT and INP, aim to find answers to ammonia related issues such as a bunkering feasibility in the Port of Rostock, new cruise port harbour structures required, cruise ship design, and ammonia bunker supply (amongst others). The project will also conduct a technical evaluation of a new propulsion system that consists of an ammonia cracker and a fuel cell, in order to compare its performance to that of a propulsion system powered by LNG.

We gathered key partners in the project for a Maritime Ammonia Insights webinar last month to learn more about the ammonia-powered cruising concept. AEA Maritime Director Sofia Fürstenberg Stott was joined by Sebastian Prochnow (Rostock Port GmbH), Donald Höpfner (Yara GmbH & Co KG), Malte Zeretzke (Carnival Maritime GmbH) and Urs Vogler (DNV). You can watch a replay of the session via the AEA’s Vimeo channel, and download the speaker presentations.

At high level, the project ambitions are to “open a path to technology leadership and market capitalization of regionally produced ammonia technologies”. The consortium will do so by finding general approaches to main challenges for zero-emission shipping, as well as exploring feasible legal and political frameworks and the economic viability and availability of ammonia as a shipping fuel.

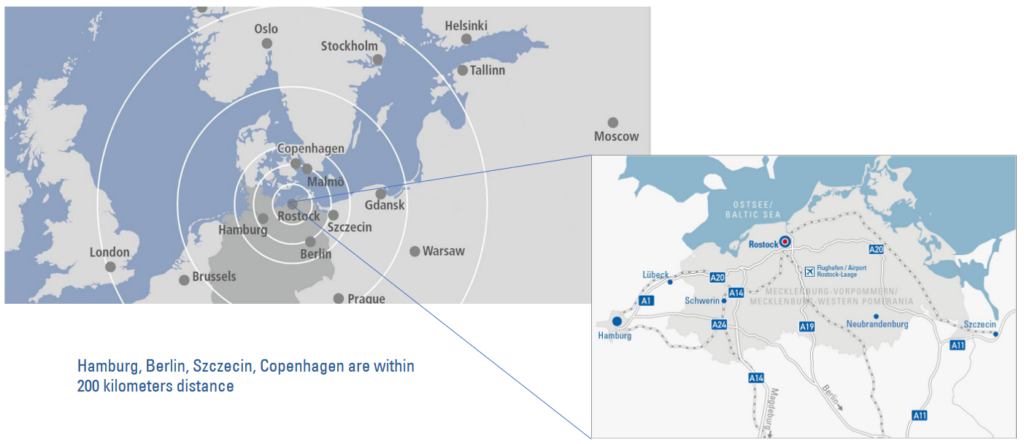

Rostock

Located in the estuary of the river Warnow on the German north coast, Rostock is a key shipping location. Hamburg, Berlin, Szczecin, Copenhagen and Malmö are all within 200 km. Rostock Port GmbH is a port operator, infrastructure owner and a landlord port authority, three quarters owned by the city of Rostock. It is the biggest German port on the Baltic Sea, and the only German deep-sea port on its Baltic coastline. Here, Yara has a chemicals terminal, and at the river mouth, the picturesque town of Warnemünde hosts the cruise terminal connected to the port. This is the backdrop to potential ammonia synergies which this project aims to explore.

Yara Clean Ammonia was established as a separate segment and business unit in 2021 to focus on green and blue ammonia. Yara has about 20% of the market share in traded ammonia world-wide, which translates to 4.1 million tonnes of ammonia transported during the 1st quarter of 2022. At the Yara terminal in Rostock, it hosts the largest ammonia storage in Germany with a current import capacity of 600,000 tonnes of ammonia per year.

Future fuels for Baltic cruise ships

Is ammonia a guiding star for cruise ships? AIDA Cruises, represented in this project by Carnival Maritime GmbH, aims to achieve net-carbon-neutral ship operations by 2050. To reach there, AIDA Cruises is working toward its 2030 goal to reduce its carbon intensity by 20% (relative to a 2019 baseline).

Recognizing biofuels as a short-term bridging technology (are expected to soon hit availability limits of sustainability feedstocks), Carnival Maritime GmbH is determined to explore hydrogen-derived options for the longer-term horizon. “Low availability of low-carbon fuels, and low maturity of high efficiency technology options”, are hurdles being faced today. Having a long-term perspective is therefore essential: “Clever engineering is needed to make cruise ships fuel-ready for a zero-carbon and zero-emission future”, says Malte Zeretzke, at Carnival Maritime GmbH.

Logistics to deliver ammonia fuel

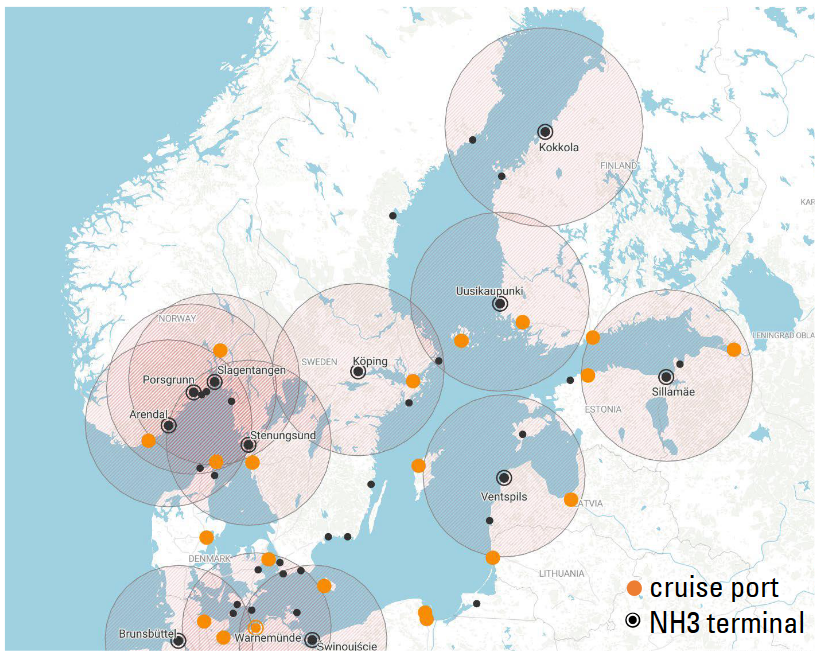

As a first work package, the project has assessed the current state of ammonia production and storage facilities across the Baltic Sea. A well-developed infrastructure was found, where existing ammonia terminals could be classified as basically suitable also for ships’ bunkering. Most of these locations are all within 100 nautical miles from the major cruise and ferry ports in the region, which is a feasible distance for a future ammonia bunker barge.

The existing presence of ammonia terminals could theoretically provide sufficient availability of ammonia to Baltic Sea cruise ships on a 14-day voyage (1-2 bunkering stops, average 1,000 tonnes at each stop), provided there was a build-out of ammonia bunker barges across the intended route network. Ship-to-ship bunkering is the transfer method of choice for these high volumes, and may also be suitable for ferries bunkering ammonia in the Baltic (between 100-1,000 tonnes at a bunkering stop).

Safe bunkering

The second work package developed a feasibility study as the basis for a future ammonia bunkering permit. Through a HAZID workshop, they assessed how bunkering of ammonia safely can take place at the Warnemünde cruise port and at the Rostock seaport through four different scenarios: ship-to-ship & truck-to-ship bunkering at the cruise port, ship-to-ship bunkering at the RoRo/ferry berth, and truck-to-ship at the cargo vessel berth.

The conclusion from this initial study is that under the current project assumptions, all options are considered feasible, from both a ship & port safety and an environmental safety perspective. Due to space limitations at Warnemünde, the truck-to-ship bunkering option at the cruise port is not likely to occur. The project will now further detail the options and their specific operational aspects, to define necessary safety zones for further advancement of an actual bunker location.

What’s next? One of the questions the panelists received during the webinar was related to how this study may inform policy makers. Engagement with the German energy ministry and Rostock municipality is planned in the near future, to further inform of the outcomes to date, especially with regards to suggested potential bunker locations and respective safety distances.

Participants were also eager to know whether cruise passengers may be more willing – being environmentally conscious – to accept a higher ticket price to assist the implementation of new fuels. The audience heard that there is currently no active push from customers to pursue new fuels, and that levers other than ticket prices – better engineering, higher occupancy trips, more attractive destinations/cruise routes – would be the first ones pulled in this decarbonization journey.