Ammonigy: Speedboats powered by green ammonia

By Julian Atchison on March 02, 2022

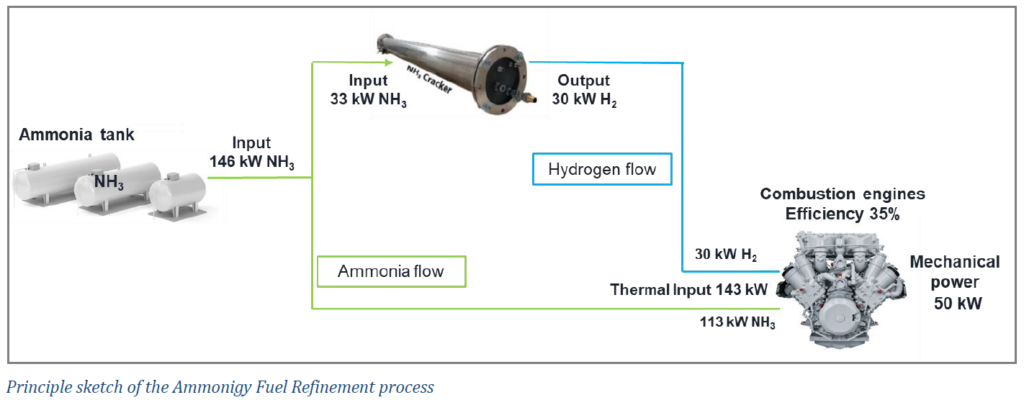

Stuttgart-based organisation Ammonigy has been developing a suite of unique ammonia-powered applications since 2020. Prototypes of ammonia-fueled road vehicles, stationary power generators and inland water vessels have all been developed based on two simple technologies: a modular cracking unit that provides hydrogen to act as an “igniter” for the ammonia fuel, and an exhaust treatment system to minimise NOx emissions from the engine. But, while the principles behind Ammonigy’s technology solutions are very familiar to our readers, using them to convert a speedboat to run on ammonia fuel is certainly new!

The GREEN AMY

The 13m long, diesel-powered Sea Ray 390 had its two Mercury V8 engines replaced by a single MAN industrial gas engine. Twelve 40kg ammonia gas tanks provided fuel, which, along with the Ammonigy Fuel Refinement (ammonia cracking) unit, were installed within the cabin of the boat.

Overall the system provided 50kW of mechanical power output – about one-sixth of the 380 horsepower the boat was rated at when diesel-powered, but much higher than required for the test speeds of <10km/hour. NOx emissions testing was performed on an identical reference engine on land, and it was determined lean operating conditions (0.98<λ<1) were optimal, with the only pollutant being ammonia slip (<20ppm). This would be fully treated by adding an SCR catalytic converter after Ammonigy’s exhaust treatment system (ironically, this would have been the setup anyway with a diesel-powered engine).

But fully converting the speedboat to run on ammonia fuel doesn’t make sense: above speeds of 14km/hour this model becomes a “glider”, which requires huge amounts of fuel to operate. Rather, the low-speed trial was meant to imitate a vessel like an inland cargo barge, and then scale-up the results.

Ammonigy based their scale-up calculations on a typical inland waterways vessel: 400kw power output on a 100 meter vessel carrying 1,000 tonnes of freight at >10km/hour over a range of 1,000km. Promisingly, the AFR cracking unit for this vessel would only need to be twice the size of the unit installed in the speedboat cabin – easily accommodated on a vessel that size. At least 26 m³ of ammonia fuel would also be required – again, a feasible fuel load for a vessel of this type that would be easily accommodated. The next step will be to implement the two pieces of technology (and a bigger MAN engine) on a barge-sized cargo vessel.

For more details, download Ammonigy’s white paper here.

Beyond ammonia speedboats

So what are the next steps? Ammonigy CEO Christian Hermle told Ammonia Energy that a barge-sized demonstration makes perfect sense, and that they are keeping their eye out for potential partners and funding in Europe. Ammonigy is currently engaged in a similar low-speed, constant-power demonstration project – engines for heavy rail transport – and expects to release those results at the end of this year.