BASF, Evonik: “biomass-balanced” ammonia for polyamide products

By Julian Atchison on October 16, 2024

Evonik receives first delivery

BASF has successfully delivered its first shipment of BMBcertTM grade ammonia to Evonik. Claiming a product carbon footprint at least 65 % lower (based on EU default values), the ammonia is produced via a biomass balanced approach:

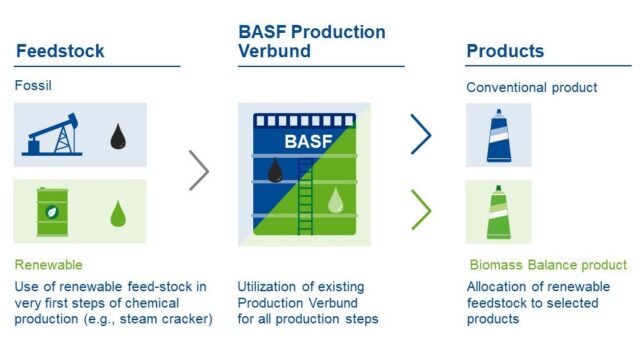

BASF applies a biomass balance approach to replace fossil resources at the beginning of the production process with certified biomethane from biowaste raw materials which are attributed to the product. The mass-balanced product is certified according to ISCC PLUS standards. In addition, BASF is using electricity from renewable sources for the manufacturing of the ammonia, further reducing its PCF.

Details of the biomass-balance approach for ammonia production, from BASF’s official press release, 7 Oct 2024

BMBcertTM grade ammonia is ISCC-PLUS certified, allowing Evonik to incorporate the raw material into its own emission accounting processes. Evonik plans to use ammonia as a raw material in the production of a range of products, including VESTAMIN curing agents for epoxy resins used in industrial flooring, marine and anticorrosive paints, shoe soles, sunglasses, gas pipes, safety-related automotive parts and others. BASF sees its mass-balanced products as “drop-in solutions”, given they have exactly the same chemical properties as the corresponding fossil-based products.

Evonik and BASF share the same vision: We are convinced that the chemical industry can transform and replace fossil with renewable feedstocks and utilities. The supply with ammonia BMBcert is a big milestone for both of us.

Jens Aßmann, Vice President Business Management Ammonia Value Chain and Operations Amino Resins at BASF, in his organisation’s official press release, 7 Oct 2024