Battolyser update: combined battery-electrolyzer technology wins industry contest, targets TRL8 in 2020

By Trevor Brown on December 14, 2018

Dutch start-up Battolyser BV was today declared the winner of Industrial Energy Enlightenmentz 2018. The award was announced at the annual Industry & Energy event, held at the Brightlands Chemelot Campus in Geleen, which this year focused on the theme When Electrons Power Molecules.

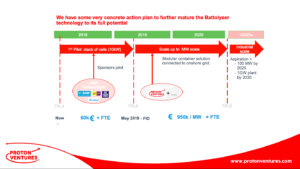

At the NH3 Energy+ Topical Conference last month, Hans Vrijenhoef of Proton Ventures gave the opening presentation, co-authored by Fokko Mulder of TU Delft, in which he described the battolyser’s robust combination battery and electrolyzer. He also mapped out Battolyser BV’s technology development and investment pathway, beginning with the kW-scale pilot plant that is already underway and expected to be operational by Spring 2019, and a MW-scale, modular, containerized plant which should be complete by the end of 2020. Reaching a technology readiness level of TRL8, Battolyser BV then aims to increase industrial scale swiftly, demonstrating a 100 MW unit by 2025 and a 1 GW battolyser by 2030.

The integration of Edison’s nickel-iron battery with robust alkaline electrolyser technology yields an efficient battery and — when fully charged — an electrolyser that can produce hydrogen and oxygen. The hydrogen can be used as chemical feedstock or be stored as fuel for seasonal storage, while the battery provides electricity storage for minutes, up to day and night. Overall energy efficiencies reach 80 to 90 percent. This development from the research group of Prof. Fokko Mulder at TU Delft is now taken forward in the start-up Battolyser BV founded by TU Delft, Proton Ventures and Mulder. A first up-scaled battolyser pilot plant is currently being realised next to Nuon’s Magnum powerplant in Eemshaven.

Utilities NL, Battolyser wins Industrial Energy Enlightenmentz 2018, 13/12/2018

In June 2018, Battolyzer BV announced a €480,000 grant from Waddenfonds, a Dutch public-sector funding agency. As we reported at that time:

The battolyser is a battery that stores electricity in the conventional galvanic manner until it is fully charged. At that point, the device uses any additional electricity supplied for the electrolysis of water and evolution of hydrogen. If the device is integrated with hydrogen buffer storage and an ammonia production train, the result will be a versatile and highly scalable energy storage system that can provide responsive grid support on all time scales from seconds to months.

Ammonia Energy, Battolyser Attracts Grant Funding, Corporate Support, 06/21/2018

The demonstration 10 kW battolyser is expected to be complete in May 2019. It is being installed on the site of the Magnum power plant, which, as a direct result of the Power-to-Ammonia study published in 2017, is currently being converted to run on hydrogen fuel, with the long-term ambition of using imported ammonia as the hydrogen storage and transportation medium.

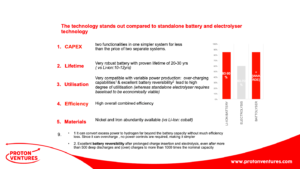

The benefits of combining two capabilities into one piece of hardware are clear, but most profound where they impact the economics of energy storage. Batteries are essential for short-duration energy storage (seconds, minutes, hours) but are not suitable for long-term storage (weeks, months, seasons) because batteries will never have the energy density of chemical fuels. According to Vrijenhoef’s presentation, 200 GWh could be stored using hydrogen with a footprint of 10 hectares (0.04 square miles) whereas, with batteries, the same amount of energy would require a footprint of 2,000 hectares (8 square miles). By bringing these two technologies together, Battolyser BV allows power plants to access both short- and long-duration energy storage markets.

The battolyser has additional economic attractions. The nickel-iron battery’s proven lifetime of 20-30 years improves significantly over the Li-ion battery (10-12 years). Combining two functions in one device reduces system complexity for the operator and, because the battery is designed to overcharge, power controls are not required. The components are plentiful and cheap, with none of the resource availability issues that impact lithium or copper markets. The battolyser has “excellent battery reversibility,” allowing for a high degree of utilization.

With its roadmap to TRL8 in 2020, and a development pathway toward 1 GW units, Vrijenhoef disclosed in his presentation that Battolyser BV has secured patents and registered its name worldwide. The company’s first sales of kW-size units is “anticipated late 2019.”

The third annual NH3 Event in Rotterdam, which is hosted by Proton Ventures, will take place on 6-7 June, 2019. We can expect a full progress report on the demonstration plant, and news of potential cost reductions from electrode development, from Vrijenhoef and Mulder at that conference.