Decarbonizing fossil-based ammonia production in North America

By Kevin Rouwenhorst on June 22, 2022

The second webinar of our new series Ammonia Project Features focused on various pathways for decarbonizing fossil-based ammonia production in North America. Blake Adair (Manager Projects, Innovation and Product Development at Nutrien) and Dr. Amgad Elgowainy (Senior Scientist and Group Manager at Argonne National Laboratory) discussed lower carbon ammonia production pathways from fossil feedstocks and the carbon intensities attached. The recording is publicly available via our YouTube channel (you can also download the speaker presentations).

Ammonia with decreased carbon footprint at Nutrien

Canada-based Nutrien is the world’s third largest producer of nitrogen fertilizer, and the world’s largest producer of potash. Nutrien has committed to decreasing its greenhouse gas emissions (scope 1-2) by 30% per tonne of product produced by 2030 (vs. 2018 baseline).

Nutrien already has various existing low-carbon ammonia plants. For example, it produces about 490,000 of low-carbon ammonia per annum in Joffre, Alberta, utilizing by-product hydrogen from an adjacent ethane cracker. According to analysis by Dr. Elgowainy and co-workers, this hydrogen has a carbon dioxide footprint about 25% lower than conventional, natural gas-based hydrogen production.

Recently, Nutrien announced its intention to build a clean ammonia facility with a capacity of 1.2 million tonnes per annum in Geismar, Louisiana. The proposed plant has at least 90% reduction in carbon dioxide emissions (scope 1-2) compared to conventional ammonia production. The front-end engineering design (FEED) phase is ongoing, with a final investment decision expected in 2023. If approved, the $2 billion ammonia production facility would begin construction in 2024, and full production is expected by 2027.

Technologies to improve carbon capture rates

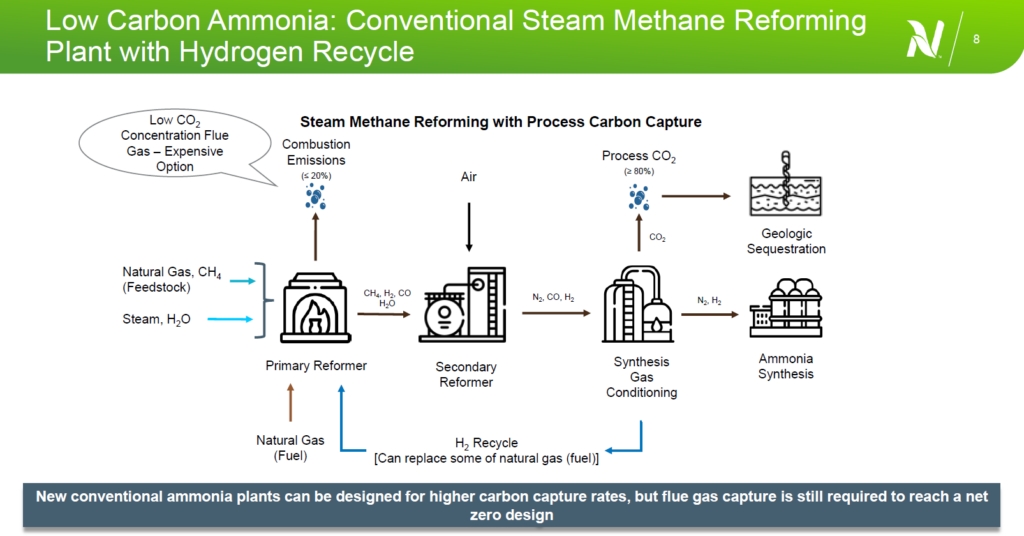

Most ammonia plants are based on steam methane reforming (SMR) for hydrogen production, in which about two third of the natural gas is used as hydrogen feedstock, and the remaining third of the natural gas is combusted as a fuel. The carbon dioxide formed during hydrogen feedstock production is concentrated and easily removed, but the flue gas from natural gas combustion contains low concentrations of carbon dioxide, which is difficult to remove. This means about one third of the carbon dioxide is difficult and expensive to capture.

One alternative to decrease emissions is to recycle some of the produced hydrogen as a fuel, thereby displacing natural gas. This results in less carbon dioxide in the flue gas, resulting in an overall higher carbon capture rate. It should be noted that this carbon dioxide should still be permanently sequestered in order to decrease carbon dioxide emissions.

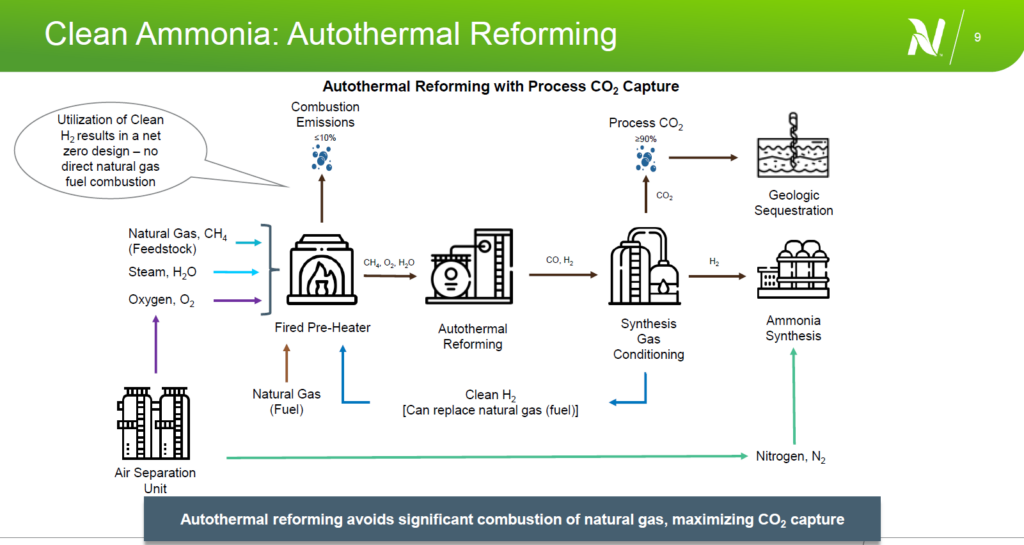

Another technology pathway for hydrogen production from natural gas is autothermal reforming. In this case, both the natural gas reforming to hydrogen, and natural gas combustion occur within the same autothermal reforming reactor. The benefit of this technology is that all carbon dioxide is available in concentrated form. According to IRENA, this allows for carbon capture rates above 98%.

Quantifying carbon intensities

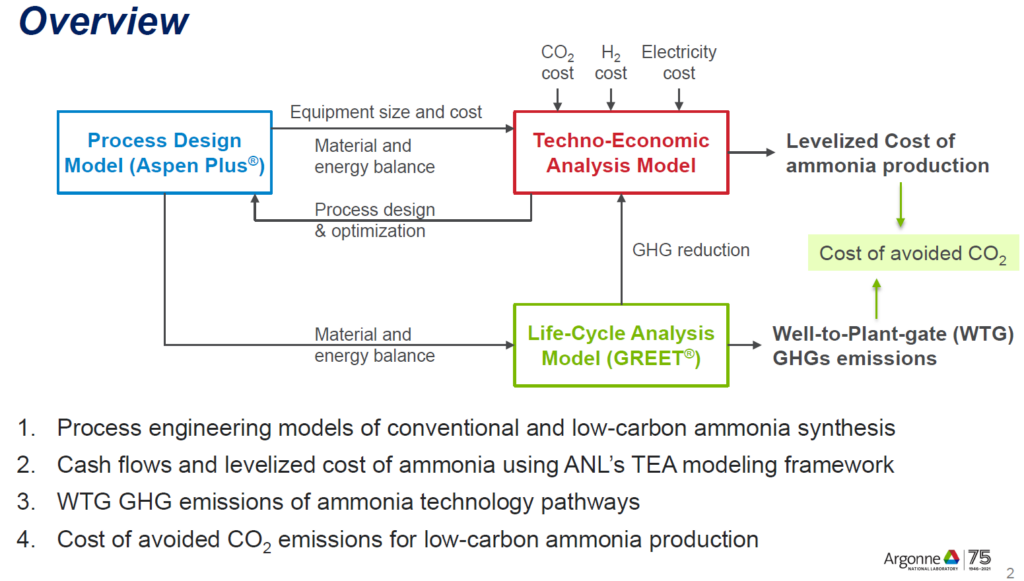

At Argonne National Laboratory, a model was developed to estimate the cost for mitigating carbon dioxide emissions from ammonia production, based on the levelized cost of ammonia production and well-to-gate greenhouse gas emissions. Inputs for these are a Process Design Model, a Techno-Economic Analysis Model, and a Life-Cycle Analysis Model. Fossil-based ammonia production pathways with and without carbon mitigation were discussed, as well as electrolysis-based ammonia production using renewable electricity or nuclear power.

The model estimates that a 55-70% carbon dioxide emissions reduction is achievable for natural gas-based ammonia production with carbon capture and storage (CCS) using the well-to-gate Life-Cycle Analysis. This includes emissions from natural gas extraction, a topic extensively discussed during our previous Project Features webinar. Methane emissions from natural gas extraction vary substantially, and should be a key focus for full supply chain decarbonization. Next to carbon emissions, other sustainability criteria should be assessed, such as the water footprint, air pollution, resource availability, long term sustainability & security among others.

The carbon avoidance cost

The model developed by Argonne National Laboratory shows carbon dioxide avoidance costs from fossil-based ammonia production are in the range of $20-120 per tonne of carbon dioxide. The main determining factor for this cost is the transport distance by pipeline, assumed to be in the range of 100 miles (interstate) to 1000 miles (cross-continent).

The carbon dioxide avoidance cost can be further decreased due to the 45Q tax credit for carbon capture projects, which provides a tax benefit for sequestering carbon dioxide. Carbon dioxide used for enhanced oil recovery (EOR) receives a $35 tax credit per tonne of carbon dioxide, while carbon dioxide for permanent CCS (not including EOR) receives a $50 tax credit per tonne of carbon dioxide sequestered. Given that the cost of CCS can be lower than $50 per tonne of carbon dioxide in some cases, this suggests more CCS projects will likely be announced.

In conclusion, fossil-based ammonia production plants with a decreased carbon footprint are emerging in North America for two reasons:

- carbon mitigation incentives from the federal government are easily available and make a substantial contribution to project costs, and

- commercially-mature technology solutions for low-emissions hydrogen production are widely available.