Engie, Siemens, STFC, and Ecuity awarded funding for green ammonia-to-hydrogen in UK

By Trevor Brown on September 06, 2019

Last week, the UK Department for Business, Energy and Industrial Strategy (BEIS) announced a “£390 million government investment to reduce emissions from industry,” with a focus on low-carbon hydrogen supply and clean steel production. As part of this investment, a consortium led by Ecuity Consulting that includes Siemens, Engie, and the Science & Technology Facilities Council (STFC), has been awarded £249,000 to perform “valuable research on the role of ammonia in the delivery of low cost bulk hydrogen for use in the UK energy system.”

The use of green hydrogen to decarbonise parts of the UK energy system is critical to the UK achieving its net zero target. However the storage and distribution of hydrogen presents a significant challenge, as production and use may not take place at the same site or at the same time.

Ammonia offers a solution to this challenge. The storage and distribution of ammonia are well established, mature practices with well-established and mature supply chains. The missing element is the cracking technology, which is in its infancy but without which, ammonia cannot be used to enable the hydrogen economy. This project will focus on the development of highly efficient and scalable cracking technology.

The project brings together cutting edge catalyst technology developed by STFC, engineering capability from Engie, green ammonia expertise from Siemens and market analysis from Ecuity to deliver a holistic approach to demonstrating the feasibility of this technology.

Ecuity Consulting press release, Partnership secures £250,000 funding for cracking green hydrogen research, September 5, 2019

BEIS investment: $390 million for low-carbon hydrogen

This project, described in the announcement as the “Ecuity Consulting - Harwell Ammonia to Renewable Hydrogen Project,” is one of 13 projects that were awarded funds last week for work in the “Hydrogen Supply feasibility phase.” Another seven projects received funding in the “Industrial Fuel Switching feasibility phase.” All together, 20 projects were awarded nearly £7 million under two specific government programs: a £20 million Hydrogen Supply program and a £20 million Industrial Fuel Switching competition.

These 20 projects all focus on “feasibility phase” work and, presumably, will lay the foundation for future implementation phase projects, for which BEIS has earmarked much larger amounts of investment. For example, the announcement includes a call for evidence in support of its £250 million Clean Steel Fund.

The full £390 million investment planned by BEIS will be targeted as follows:

£40 million Hydrogen and Fuel Switching Innovation Fund to explore how the technology can be rolled out across the UK to help cut emissions

£100 million competition to enable greater supply of low carbon hydrogen for use across the economy to help businesses decarbonise

£250 million Clean Steel Fund to support the iron and steel industry, which currently accounts for 15% of industry emissions, to transition to a low carbon future, including using hydrogen

UK Department for Business, Energy and Industrial Strategy press release, Hydrogen-powered distillery to produce sustainable gin, August 29, 2019

These sums are in addition to the previously announced £100 million investment in the government’s “Industry and CCS Innovation programme for low carbon industrial innovation, which includes both hydrogen and Carbon Capture Usage and Storage (CCUS).”

For reasons best known to BEIS, all this news was hidden at the bottom of an announcement about decarbonizing a small gin distillery.

Siemens Green Ammonia Demonstrator

The “Harwell Ammonia to Renewable Hydrogen Project” is an offshoot from an existing project, the Green Ammonia Demonstrator, which Siemens is operating at the STFC Harwell campus, near Oxford, in the UK. As we reported when the pilot plant began operating in June 2018, it connects fluctuating wind power to an electrolyzer, which produces renewable hydrogen to feed a 30kg/day Haber-Bosch unit. The project also includes a dedicated ammonia engine to generate power from ammonia fuel, demonstrating the feasibility of the full round trip: renewable power to ammonia, energy storage in the form of ammonia, and ammonia back to electricity.

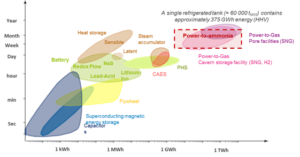

The argument for using ammonia for energy storage is not to compete with batteries, which excel in short-term, small-scale storage markets, but to address long-term and large-scale energy storage markets by providing a carbon-free alternative to conventional chemical energy stores: fossil fuels.

In the future, most decarbonized economies will continue to face energy imports or exports, transcontinental supply chains, and long-term storage demands (hoping, of course, that distributed generation and electrification will also provide energy independence for many). In this scenario, where hydrogen solves the problem of carbon dioxide emissions from fossil fuels, ammonia solves the problem of hydrogen storage and distribution at scale.

The Green Ammonia Demonstrator looked at ammonia for energy storage, generating electricity using ammonia as a fuel. This new project looks at ammonia for hydrogen storage, generating renewable hydrogen by “cracking” the renewable ammonia molecule.

Ian Wilkinson, Green Ammonia Programme Manager, Siemens plc, said: “The use of ammonia as a hydrogen vector can help make a UK hydrogen economy real, by providing a practical way of storing and transporting hydrogen in bulk. Efficient and scalable ammonia cracking technology is the final link in the green hydrogen chain …”

Mechanical Engineer, Tristan Davenne from STFC said “… The funding received from this BEIS Hydrogen Supply Competition has allowed STFC to draw on multi-disciplinary expertise in catalysis and mechanical engineering to design a novel and efficient ammonia cracker. This can be integrated with the green ammonia plant and used to demonstrate the production of green hydrogen from ammonia.”

Ecuity Consulting press release, Partnership secures £250,000 funding for cracking green hydrogen research, September 5, 2019

This is important work, and similar projects are already underway elsewhere, most notably the CSIRO hydrogen purification membrane technology, now being further developed by Fortescue Metals Group, which cracks ammonia and purifies the hydrogen to the stringent fuel quality requirements of the PEM fuel cell. The CSIRO technology aims to support Australia’s energy export economy by facilitating the use of ammonia-delivered hydrogen in East Asian transportation markets.

Engie’s cost analysis, at the Ammonia Energy Conference

Engie, the global energy and services group, will be supporting this new project by “providing our research capability, as well as UK & wider-global energy and technical expertise.”

Engie is becoming increasingly involved in ammonia energy projects. Earlier this year, Engie announced a partnership with Yara to study the feasibility of solar ammonia production in Australia’s Pilbara region. And, in July, Chilean ammonium nitrate producer Enaex announced another Engie feasibility study for “the design, construction and operation of a green ammonia production complex based on renewable hydrogen” (I will be writing about this project in greater detail in the coming weeks).

Insight into Engie’s role in this new project might be gleaned from a forthcoming presentation at the Ammonia Energy Conference, in Orlando, FL, November 12-14.

According to the abstract for the presentation, Ammonia As Hydrogen Carrier to Unlock the Full Potential of Green Renewables:

In this presentation, the potential of ammonia as hydrogen carrier for large scale hydrogen transportation will be discussed on the basis of both modelling and experimental work …

Thanks to the in-house HYTAC calculation tool (Hydrogen Transportation Analysis and Costing) developed within ENGIE Lab CRIGEN to compute the hydrogen transportation cost, several large scale hydrogen production and transportation scenario are analyzed for various renewable electricity sourcing and according to different demand scenario and transportation distance. The potential of ammonia, liquid organic hydrogen carrier, methanol and SNG as hydrogen carrier for the long distance transportation of green hydrogen from several areas of important renewable energy technical potential to oversea utilization point is analyzed and compared. In the presented work, the entire process value chain is considered from renewable electricity sourcing, green hydrogen production, hydrogenation process, maritime transportation, dehydrogenation and final utilization of hydrogen for mobility or industrial applications. A cost breakdown analysis is provided helping to define the main contributor to the levelized cost of delivered energy and demonstrate R&D efforts to be done to reach a economic profitability.

The question of green hydrogen recovery using a centralized or a decentralized ammonia cracker is still unanswered. First, centralized fired heated ammonia cracker does not exist so far at size to produce hundred of tons of hydrogen per day. Then, considering the stringent limit in ammonia content into the hydrogen feeding a PEM fuel cell (0.1 ppm), selective dehydrogenation reactor are required in order to reduce purification cost of the forming gas produced. In this presentation, first results of experiments performed on an innovative compact decomposition reactor will be introduced. Obtained performances will be compared on the technical and economic point of view with a designed centralized cracker.

Camel Makhloufi, Pierre Olivier, Nouaamane Kezibri, Alexi Liedes (R&D – ENGIE Lab CRIGEN), Ammonia As Hydrogen Carrier to Unlock the Full Potential of Green Renewables, Ammonia Energy Conference 2019

The full schedule for the Ammonia Energy Conference 2019 has been published and registration is now open. Engie’s presentation will be given at the end of the second day of technical presentations, which take place November 12 to 14, in Orlando, FL.