Green Ammonia at Oil and Gas Scale: Ammonia Energy Conference 2020 Keynote

By Julian Atchison on December 10, 2020

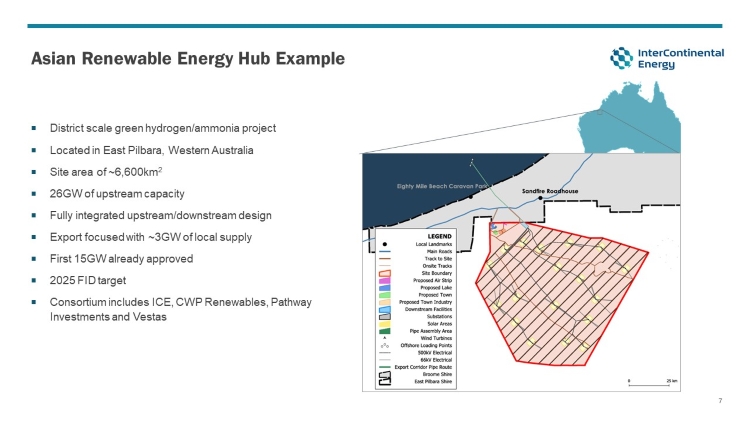

What does green ammonia look like at oil and gas scale? To open the Ammonia Energy Conference 2020 – and give us some insights into this question – we were thrilled to welcome Alex Tancock, Managing Director of InterContinental Energy (ICE). Since 2014 ICE has been in the business of identifying the new generation of “Green Supergiants”: green hydrogen and green ammonia fusion projects based on large-scale renewable energy. Alex was excited to pass on the key lessons learnt from the development of ICE’s first publicized project – the Asian Renewable Energy Hub (AREH) in north-western Australia.

A template for “Green Supergiants”

By 2050 the world will be producing somewhere between 0.5 and 1.5 trillion tonnes of green hydrogen every year, and ICE believes green ammonia represents the best vector to market for this product. This is a big leap from where we are now – so how do we get there? ICE has settled on a relatively simple template for large-scale green ammonia production:

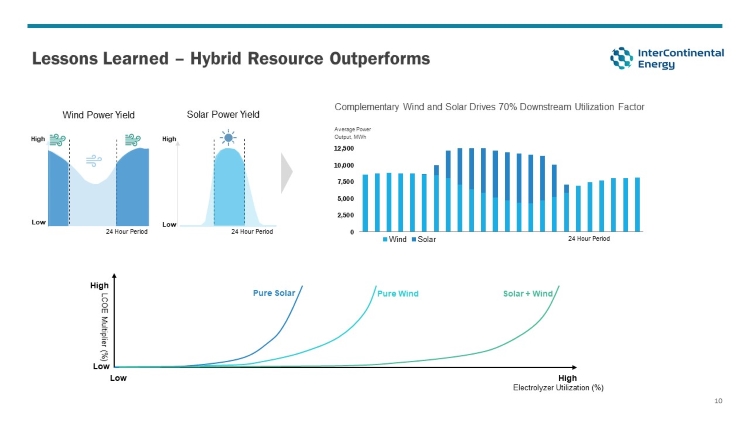

- Massive build out of world-class, wind-solar hybrid energy generation (wind >8.5 m/s; solar >1900kWh/m2) on sparsely or uninhabited coastal sites

- Use of desalinated water in hydrolysers (no use of at-risk water sources like rivers or aquifers)

- Export via VLGCs (Very Large Gas Carriers, 50,000 tonnes to start, but likely double that size in the future)

AREH is a prime example: a ~6,600km2 uninhabited, coastal site with a planned 26GW of upstream wind-solar power generation and export of green ammonia via an off-shore fuelling tower. The massive overbuild of hybrid wind-solar energy generation (26GW vs. 14-15GW of installed electrolysers) is deliberate: 3GW at least is reserved for local supply and the development of industry (eg. green steel) in the East Pilbara region, and there’s been a surge in interest for power offtake in the last twelve months. ICE projects some groundbreaking prices for AREH output post-2030: upstream solar/wind <2c/kWh, green hydrogen at <$1.5/kg and green ammonia at <$350/ton post-2030.

What’s needed

But as impressive as these statistics are, AREH is a drop in the ocean compared to what’s needed. AREH’s green ammonia and green hydrogen output would represent 1-2% of the global traded LNG market in energy equivalents annually. In the power sector, this would be equivalent to 40% of Japanese coal-fired generating capacity co-firing with 20% ammonia. In the maritime sector, this would fuel just 200 of the globe’s 10,000 large container vessels running on 100% ammonia. In transportation, this could fuel one million long-haul heavy duty trucks, which is less than one sixth of just the European market.

Many AREHs are needed in the future to supply the volumes of green ammonia and green hydrogen the world will be demanding.

The advantages of scale

But scale shouldn’t be viewed with trepidation. In Alex’s experience, scale actually unlocks the full potential of these “Green Supergiants”: cheaper CapEx costs, increased reliability of hybrid renewable energy power generation (at least 70% in the case of AREH), large volumes of redundancy and modularity, as well as the advantages afforded by construction over long time-frames. When considering the sheer volume of consumer demand we know exists, overproduction won’t be an issue for the green ammonia industry in the coming decades. And, when looked at through the lens of decarbonisation and emissions targets, these projects will be vital to international climate action.

Ultimately, Alex sees the names of the “Green Supergiants” being part of the global energy consciousness by 2050, just like the names of the biggest oil fields – Safaniya, Kashagan etc. – are well-known today. Coming together in forums like this to share lessons and project templates is a priority, but acceleration to scale is the next challenge.

Q&A

How do sizing decisions for Haber Bosch (HB) reactors help buffer any variability?

A “rocks and pebbles” approach to HB reactors builds in valuable system variability for ammonia production. Large, world-class HB reactors don’t enjoy being switched on and off, but smaller modules don’t mind as much. You only have the luxury of these design choices at scale though.

Tell us more about engagement with Traditional Landowners and ICE’s approach to a sustainable workforce.

The AREH team is proud of its world-leading effort in engaging with traditional landowners and local First Nations communities , and this began on day one of the project. ICE’s benchmark isn’t “what is the minimum required?”, but “what is the right thing to do for the long-term benefit of the community?”. This is also the approach taken with regards to the future AREH workforce. A culture of FIFO and DIDO (fly-in, fly-out and drive-in, drive-out) work in regional Australia has destructive consequences for mental health and home life, and the decision of the AREH team was to build a town where whole family units could live and find meaningful employment.

Do you see much of a future for grey ammonia?

Grey ammonia producers should be worried about stranded assets. Even if green ammonia doesn’t reach parity cost until (best case) 2040, that’s not far away if you’re building something with a 50-year economic life. And remember, customers will be willing to pay a little more for certified green product. This month we’ve seen a massive announcement from Fortescue Metals Group in the renewable energy build-out/green ammonia space (ambition of 235GW globally), so the risk for first movers is decreasing every month.

You can download the slides from this keynote, Green Ammonia at Oil and Gas Scale. If you wish to view the archived video of the keynote speech and Q&A session, please register for the conference to access all session recordings. You can also browse and download all of the Ammonia Energy Conference 2020 presentations.