H2Pro targets tonne-per-day scale renewable hydrogen capability by 2030

By Geofrey Njovu on March 16, 2023

Sumitomo Corporation has signed an MoU with H2Pro, an Israeli renewable hydrogen production technology company, to jointly work towards commercial scale production of renewable hydrogen. Through this partnership, Sumitomo Corporation will support H2Pro’s demonstration experiment in Israel this year (200kg per day) as the first step towards the goal of achieving tonnes-per-day scale production of renewable hydrogen by 2024. The two companies will also consider joint manufacturing of renewable energy production equipment in the future.

A highly efficient, membrane-free water electrolysis method

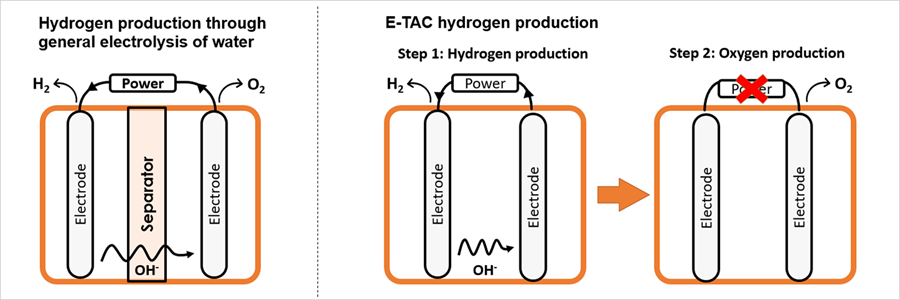

Low efficiency in the electrolysis process can lead to high hydrogen production and operational costs, and is considered one of the main constraints impeding commercial scale production. H2Pro has developed a new method for water electrolysis, called Electrochemical, Thermally Activated Chemical water splitting (E-TAC). While oxygen and hydrogen are generated simultaneously in conventional electrolysis and require separation by a sequestration membrane (which requires precious metals and is therefore costly), the E-TAC method generates oxygen and hydrogen separately, which eliminates the need for the membrane in a simpler and more efficient process (~75% for conventional electrolysis vs 98.7% for the E-TAC method).

The electrochemical magic at the heart of the E-TAC system is based on a property of nickel(II) hydroxide (Ni(OH)2), a compound that is widely used in rechargeable electric batteries. When an anode is composed of Ni(OH)2, the arrival of hydroxide ions during cell operation produces a chemical reaction in which the Ni(OH)2 is converted into nickel oxyhydroxide (NiOOH) plus a quantity of free electrons that can flow to the cathode.

This reaction continues until the number of Ni(OH)2 molecules that can be readily converted to NiOOH starts to dwindle. When that point is reached in the E-TAC system, the circuit is interrupted and electric current ceases to flow. In that environment, the NiOOH molecules spontaneously break down into Ni(OH)2 and O2. This process is accelerated by increasing the temperature in the cell. For the bench-scale version, the step 1 and step 2 temperatures were 250° C and 950° C, respectively. When the Ni(OH)2 has been regenerated, circuit continuity is restored and hydrogen generation begins anew

Description of the E-TAC chemical process, from “Israeli Group Develops New Electrolysis Technology”, Ammonia Energy Association 8 October 2019

H2Pro’s evolution since 2019

H2Pro emerged from the Technion-Israel Institute of Technology and has expanded significantly since its establishment in 2019, having run two major funding rounds; a $22M Series A funding round in 2021 (led by Breakthrough Energy Ventures and Sumitomo’s Israeli venture capital arm IN Venture), and a further $75M funding round in 2022 (led by Yara, Horizon Ventures, Temasek and others).