Mitigating emissions risks from ammonia-powered vessels

By Julian Atchison on March 20, 2023

Mærsk Mc-Kinney Møller Center: challenges, but emissions “not a showstopper”

Technology solutions to manage emissions from ammonia-powered internal combustion engines will be commercially available on a similar timeline to the engines themselves, a new report from the Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping concludes. The authors also conclude that the increased scrutiny on the possible risks of ammonia combustion emissions will be beneficial, as it will necessitate a proactive approach from stakeholders:

Increased focus has been placed on the emission risks of ammonia as a marine fuel during the design and development on ammonia DF ICEs, which can give confidence that safety and emissions expectations are being properly set from the beginning. This proactive approach is also informed by the learnings from the introduction of LNG as a marine fuel where methane slip was not fully understood and addressed upfront.

Conclusions, from Managing Emissions from Ammonia-Fueled Vessels, Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping (March 2023)

When considering the potential emissions of N2O – the ammonia combustion by-product with the greatest potential greenhouse effect – the authors expect that engine developers & vessel owners will not accept a level more than 0.06 g/kWh, roughly twice that of current, conventionally-fueled maritime engines. Interestingly, the authors note that engine designers are currently:

…targeting a scenario where acceptable ammonia slip and N2O emission levels are achieved without the need for after-treatment technology. NOX regulatory compliance would then be achieved with after-treatment, similarly to other fuels.

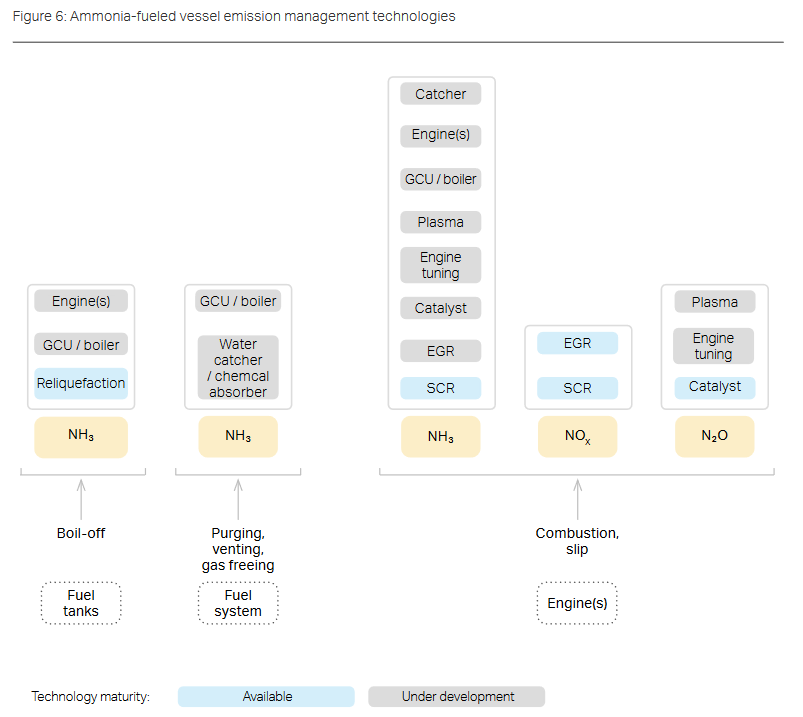

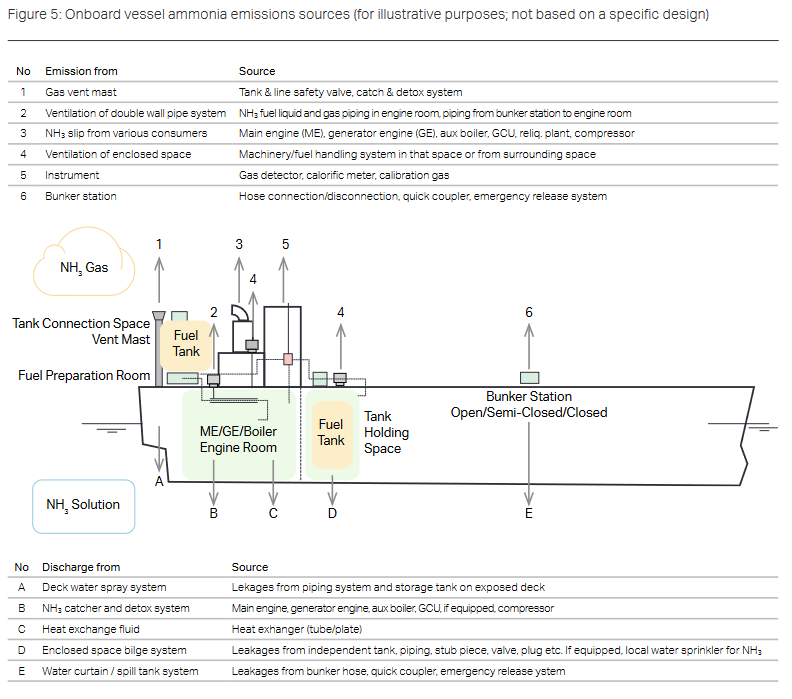

Emission management technologies, from Managing Emissions from Ammonia-Fueled Vessels, Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping (March 2023)

Suggesting a high level of confidence from the industry that emission challenges will be met. In terms of the NOx treatment technologies available, the report details a number of possible scenarios on-board a vessel and the current suite of technologies available. Though most of these technologies are still under-development for use with ammonia engines, their use with conventional, fossil fuel engines is well established.

Key knowledge gaps

In the absence of industry-wide emissions limits from ammonia internal combustion engines, the report authors had to set their own maximum levels. Future thresholds will only be able to be set once extensive testing data is available, leaving a current void in understanding. The authors also note the classification societies all set different emissions thresholds in their ammonia fuel guidelines, so industry-wide discussion and negotiation will be required to set a common standard.

On the idea of a common standard, the authors emphasize that all stakeholders – engine manufacturers, NOx mitigation technology specialists, regulators, ship owners and the like – must work together to ensure different pieces of the puzzle are not developed in isolation. With retrofit & newbuild costs for ammonia-powered vessels likely to be a huge factor in decision-making, standardisation, efficiency and common safety standards will all be critical to ensuring success.

And, while the tank-to-wake emissions savings of ammonia fuel are now well understood, we are missing the full picture of the well-to-tank emissions of ammonia fuel – particularly CCS-based ammonia. The authors point out that upstream, fugitive methane emissions associated with gas exploration would need to be factored into the use of “blue” ammonia fuel.

You can download the full report here.