Producing cheap, clean hydrogen: new updates

By Julian Atchison on December 08, 2021

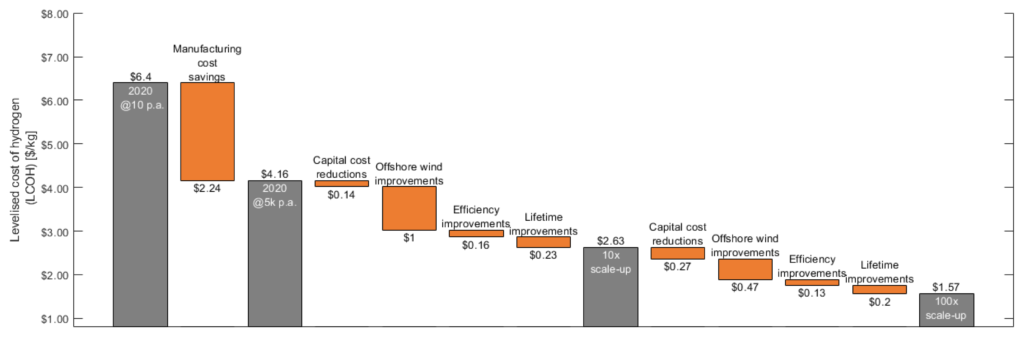

Key techno-economic drivers reducing the cost of hydrogen

A team at Durham University has shown that a massive scale-up of PEM electrolyser manufacturing capability can slash the capital costs of producing electrolyser units by up to 70%. Mass manufacturing would also have a large impact on the price of hydrogen, with deployment & installation of the produced electrolyser units then driving down the $/kg cost even further. The authors use a baseline production capacity of ten 200kW PEM electrolyser units per year for a given factory, noting that the largest PEM electrolyser factory in the world currently has 30 MW production capacity (~150 units). Planned multi GW factories will be capable of producing 5,000 of these units per year per GW of production capacity.

The authors estimate that the current, baseline cost of hydrogen ($6.40/kg) would be pushed down to $4.16/kg if production capacity was lifted to 5,000 units per year. Improvements in offshore wind turbine technology and a ten-fold scale-up of current installed electrolyser capacity further reduces the cost of hydrogen to $2.63/kg, with a one hundred-fold scale-up further reducing the cost to $1.57/kg. A similar pattern holds for the capital cost of electrolyser units: a baseline of $1990/kW, to $590/kW (production capacity increases) then on to $431/kW and $300/kW (installed capacity increases).

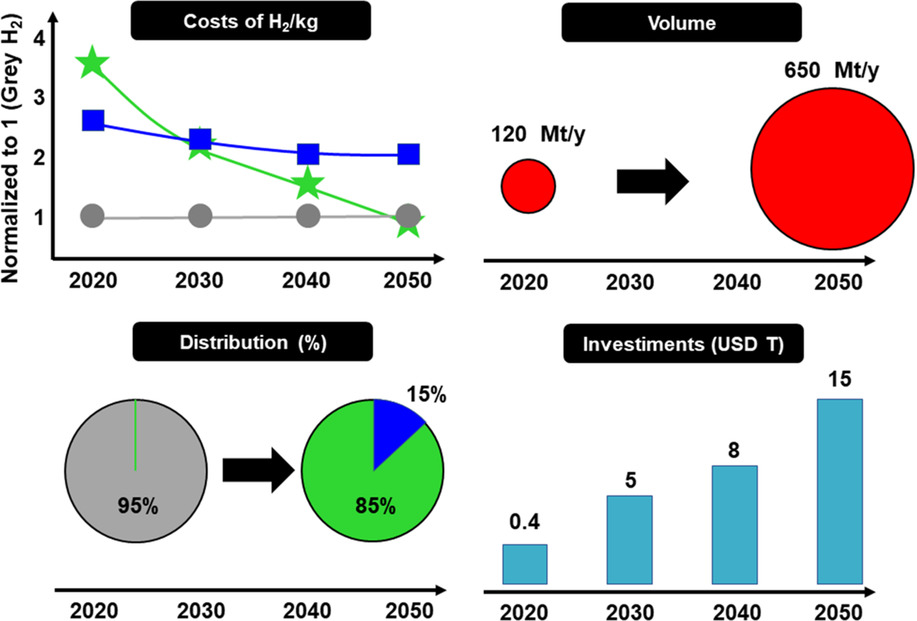

Avoiding water competition in hydrogen production

In their review of different production pathways, a team from the University of Campinas has proposed more focus on electrolysis of waste and seawater to produce hydrogen. The use of water sources unfit for human consumption to produce hydrogen represents an opportunity to “produce clean energy with social responsibility”, according to the authors.

Prototypes and small-scale demonstrations of wastewater & microbial electrolysis cells exist and show promise (especially if deployed in a distributed, point-of-use fashion), but significant material engineering obstacles stand in the way of seawater electrolysis. The authors note that progress has been made applying protective layers to electrodes to block the approach of interfering species, and that promising work is proceeding in high-performing catalysts that are a mixture of Pt and earth-abundant metals.

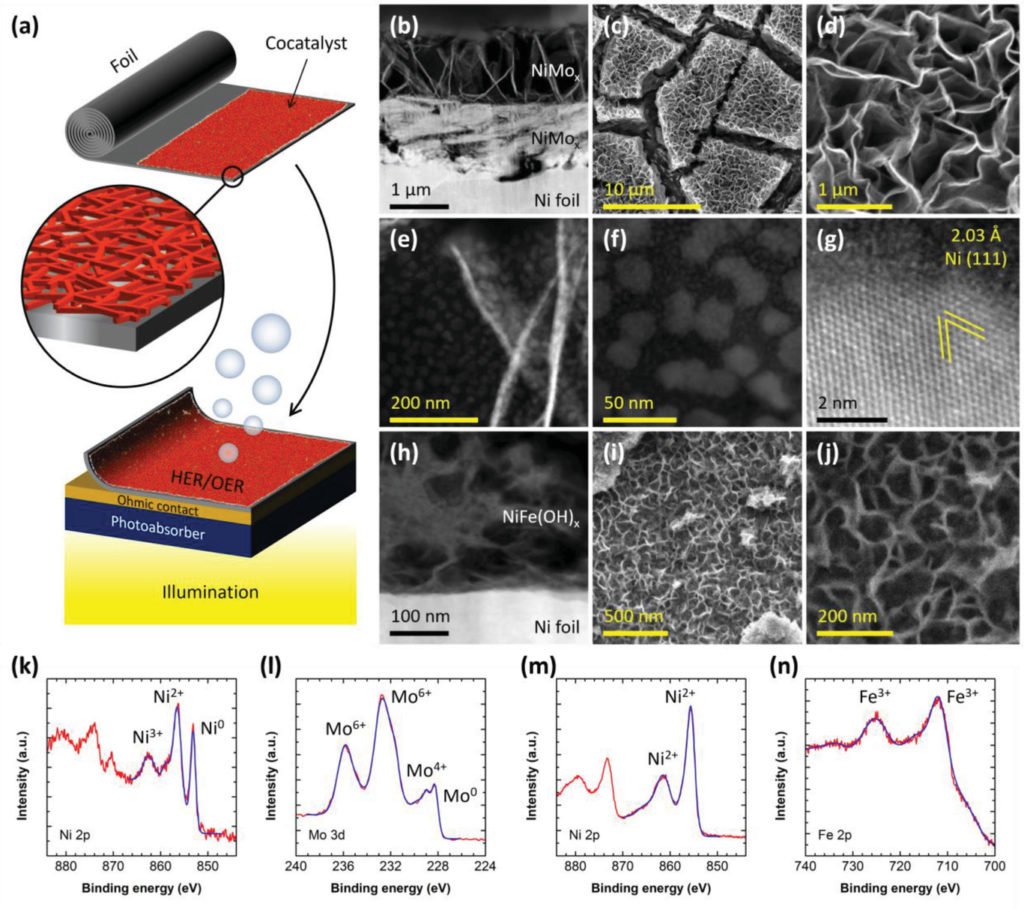

New catalysts for hydrogen production from sunlight

And a team from the Australian National University has demonstrated a new pathway forward for hydrogen production directly from sunlight. A new “photoelectrode” design incorporates optimised photoabsorbers (Si and GaAs) with an earth-abundant cocatalyst (in this study, a Ni-based foil) achieves a solar-to-hydrogen efficiency of 13.6% and maintains an efficiency of over 10% for longer than nine days – results previously unreported in solar water splitting systems.

In an interview with Australian press, the authors explain that their approach solves a common stability issue with photoelectrodes by using the Ni-based cocatalyst foil to shield the operational surface from chemical degradation. The possibility of combining solar photovoltaic cells with solar water splitting cells on household rooftops also presents an exciting opportunity: distributed, small-scale green hydrogen production that can be used onsite to offset intermittent renewable energy generation.