Recovering ammonia fuel from wastewater & agricultural waste

By Julian Atchison on December 08, 2021

Wastewater

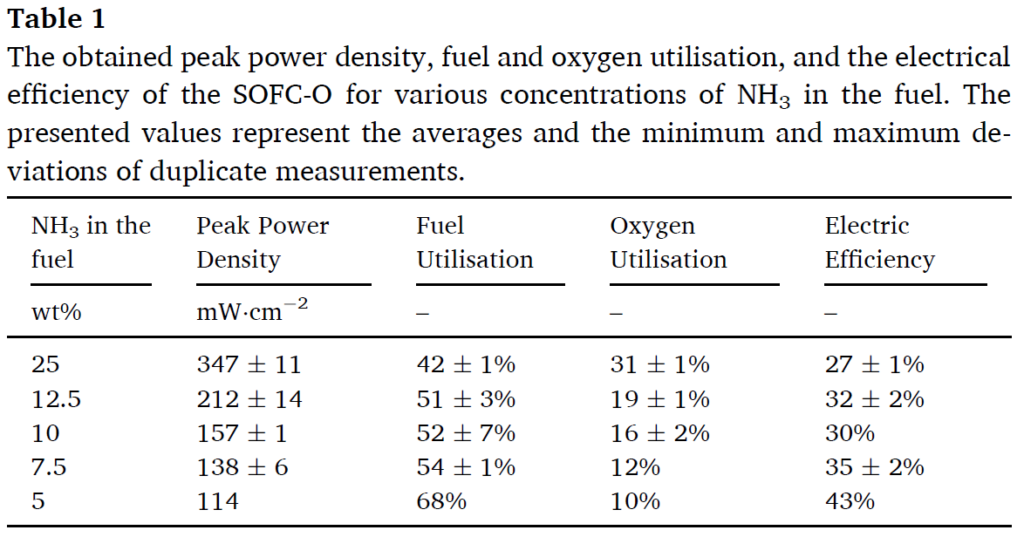

A team from the Delft University of Technology has demonstrated that ammonia recovery in the form of gaseous ammonia-water mixtures (via vacuum membrane stripping of a wastewater feed) can be used to power a solid oxide fuel cell (SOFC). Promisingly, the integrated setup also produced more power than it consumed. The highest ammonia concentration recovered by the experimental setup was 11 wt%, from feedwater containing 10g/L ammonia at a slightly elevated temperature (35 degrees). As little as 5 wt% ammonia was required to successfully power the SOFC.

The authors noted that the observed cracking efficiency of ≥95% in their setup was less than reported for previous SOFC studies (the combination of high operating temperatures and presence of nickel-based catalysts in SOFCs cracks the ammonia fuel into hydrogen, which then is consumed at the anode). But, the authors also note that “dry” (or anhydrous) ammonia (70 wt%) was the fuel of choice for these studies – recovery via vacuum membrane stripping cannot achieve a wt% this high. So while more optimisation work of their approach is required to ensure maximum cracking, this study demonstrates a viable pathway forward for ammonia recovery & utilisation from wastewater feeds.

Pig waste

A new UK consortium including the Agriculture and Horticulture Development Board (AHDB), Beta Technology, Duynie, Projex Solutions, the University of Leeds and a commercial pig farm in North Yorkshire have received £600,000 in government funding to demonstrate a novel solution to harvest green ammonia from pig waste slurry (PigProGrAm). Technical details are limited at this stage, but reducing ammonia emissions from agriculture in the UK is a priority focus of the AHDB. Last month a team of global researchers estimated 60% of particulate air pollution (PM2.5) in the UK originates as ammonia emissions from farms, and that the introduction of simple mitigation methods could save £23 in health damage for every £1 spent in the UK. Recovery & utilisation projects like PigProGrAm offer further possibilities, particularly as the UK moves towards the use of green hydrogen and ammonia fuels.

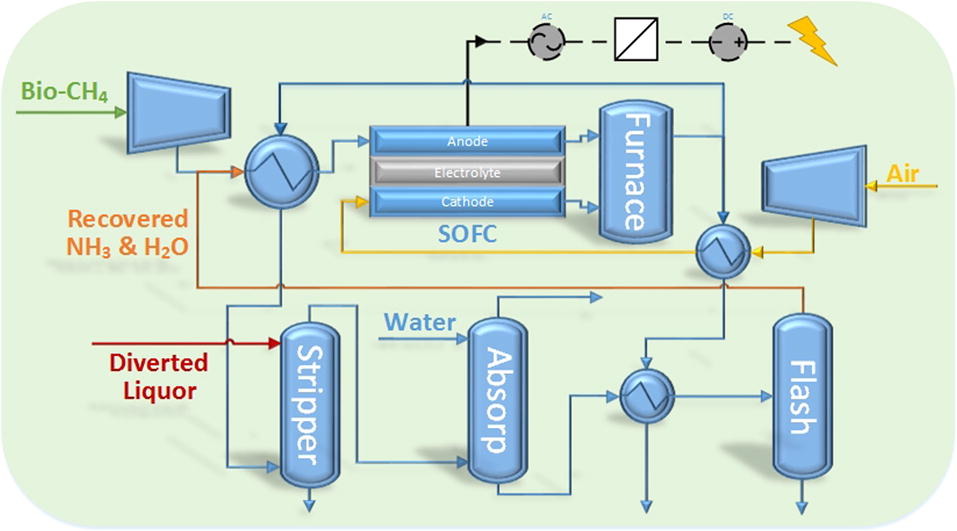

The University of Leeds has experience in the ammonia recovery & utilisation space. In 2019 a team modeled ammonia recovery from digestate liquor at a wastewater treatment plant (WWTP) for use in a SOFC. This ammonia would otherwise have to be destroyed via time and energy-intensive processes for the overall effluent to be safe for discharge back into the environment. The results suggested 82% of ammonia could be successfully recovered, with the integrated setup producing electrical power at a higher efficiency than biogas combustion (a widely-used method of power generation in WWTPs). The combined findings – decreased energy consumption by avoiding treatment processes & increased on-site power generation – were calculated to save 3.5 kg CO2e per person served by the WWTP every year.

Poultry waste

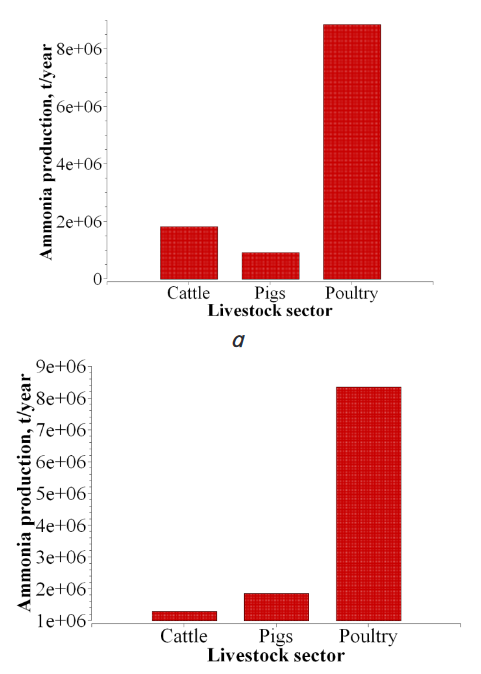

A team from the Ukrainian National University of Food Technology has proposed a new method of sourcing useable ammonia fuel from poultry waste. By carefully regulating of the levels of ammonium present in their experimental biogas reactor during anaerobic digestion, both ammonia recoverable from solution and a highly concentrated biogas product were successfully obtained. Although the authors calculated their production process requires 111GJ per tonne of ammonia produced (cf. Haber Bosch 38 GJ/tonne), scaling this process up at poultry farms, adding co generation facilities and utilising waste heat from biogas combustion would make the comparison far more favorable (and the process economically feasible).

Poultry waste has huge potential for ammonia production on farms. It has the highest nitrogen content of livestock waste and – although on a per animal basis daily waste production is relatively small – much higher numbers of poultry are reared on a farm of a given size (compared to cattle or pigs). The authors estimate that potentially 8 million tonnes of ammonia per year could be generated from poultry waste in both the US and the EU via their anaerobic digestion process.